AI-Assisted 3D Slicing Software Simplifies Dental 3D Printing Process

The software simplifies the 3D printing process so users don’t need special design training.

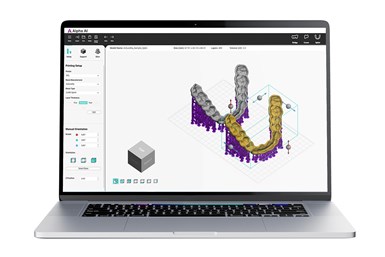

Ackuretta’s Alpha AI slicing software enables optimal AI-generated supports and orientation with just one click. Photo Credit: Ackuretta

Dental 3D printing provider leader Ackuretta offers an AI-assisted 3D slicing software, Alpha AI. This 3D printing slicing software is an evolution of Ackuretta’s Alpha 3D and is said to include several improvements from its predecessor.

The software enables optimal AI-generated supports and orientation with just one click. The AI-assisted slicing software is designed to orient, stack, nest and build supports for 3D prints with the click of a button, providing users with the performance and results they want, in a fraction of the time.

The company says extensive research has driven it toward artificial intelligence as the next logical step in its journey to make 3D dental printing accessible to everyone. Also, the technology is said to provide predictable results every time.

Alpha AI offers a streamlined process to guarantee success and eliminate human error. Users simply import an STL file on the software, click the icon for the desired application and start printing in seconds.

“Up to 75% of 3D printed applications result in failure because of poor orientation. Some clinicians and dental technicians have to go through a learning curve — which leads them to experience failed prints due to a few reasons, such as choosing the wrong printing parameters, not using the correct resin, lack of training and dealing with complex dental 3d printing software,” says Ayush Bagla, Ackuretta CEO. “Alpha AI comes to solve that exact problem. It uses machine learning to analyze data from thousands of real designs and comes up with the optimal orientation for a given application, including adding the necessary supports. Achieve the best result with just one click!”

The software has a universally compatible STL format for CAM software. Alpha AI enables users to orient an application, add the necessary supports and save it not only as i3dp and ibf (Ackureta Solution proprietary file format) but also as an STL file. The company says it aims to empower its customers by offering them a truly open system — for everything from 3D printing solutions to digital dentistry software. Dental experts can configure the print they want on Alpha AI (such as placing it with the right orientation and adding supports) and export the STL file to use on any other 3D printing CAM software specific to non-Ackuretta devices for printing.

Initially, the software will be capable of orienting and creating supports for splints, crowns, bridges and surgical guides. However, the company plans to offer regular updates and improvements every three months to add new features and functions to the dental 3D printing software.

The software is available in two versions — standard and premium. The standard version maintains the original features from ALPHA 3D with an improved UI/UX and includes a 14-day free trial to test the upgrades included in the premium version. After the trial, users can buy a 30-day or 365-day subscription to the premium version.

- Check out our Medical & Dental zone to learn more about some of the latest innovations in dental 3D printing.

Related Content

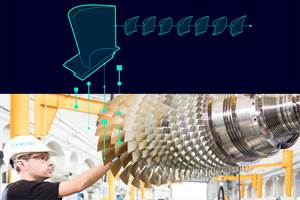

PhysicsX, Velo3D Partner to Provide Engineers with AI Simulation Tooling

The collaboration gives Velo3D customers access to AI-enabled physics simulation and optimization capabilities, and gives PhysicsX customers increased manufacturing flexibility to produce their most advanced concepts.

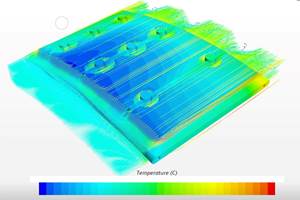

Read MoreSiemens’ Engineering HEEDS AI Simulation Predictor Optimizes Additive Manufacturing

The HEEDS AI Simulation Predictor empowers organizations to take full advantage of the digital twin to optimize products through advanced state-of-the-art artificial intelligence with built-in accuracy awareness.

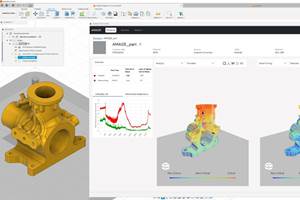

Read More1000 Kelvin’s AMAIZE AI Co-Pilot for Additive Manufacturing Now Available for Autodesk Fusion

The AMAIZE software is an “AI co-pilot” for engineers, predicting print issues upfront, performing corrections and generating industrial-grade, ready-to-use print files specific to a machine.

Read MoreVoxel Developing AI Alternative to Generative Design

Newly opened Ohio facility is where geometric cells are made and tested to inform the machine learning system that will “know,” without computation, what 3D printed form satisfies a given set of needs.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More