With the launch of Artemis I, NASA is entering a new era of space exploration. This is the first mission of the program, which will eventually build a sustained human presence on the moon to prepare for exploration of Mars. It also marks the first launch of NASA’s Space Launch System rocket and Orion capsule, both of which include 3D printed components. On this episode of AM Radio, Stephanie Hendrixson and I examine how 3D printing is enabling Artemis I, and future applications for 3D printing in space travel. Listen to the episode above, or read on for the show notes and transcript.

Transcript

Julia Hider

The AM Radio podcast is brought to by the Additive Manufacturing Conference at IMTS. The leading industry event focused on 3D printing for production co-located with North America's largest trade show dedicated to manufacturing equipment, the AMC takes place September 14th and 15th at Chicago's McCormick Place. The Conference takes a practical applications-based look at the machines, materials and methodologies being used to 3D print functional components, including both tooling and end use production parts. The event is designed for owners, executives and engineers, as well as OEMs involved in durable goods manufacturing. Join the Additive Manufacturing team in Chicago for a day and a half of conference sessions and networking opportunities, find more information and register at AdditiveConference.com.

All right, welcome back, Stephanie. I want to talk to you about Artemis, but unfortunately, I don't mean your cat.

Stephanie Hendrixson

Oh, she'll be disappointed to hear that.

Julia Hider

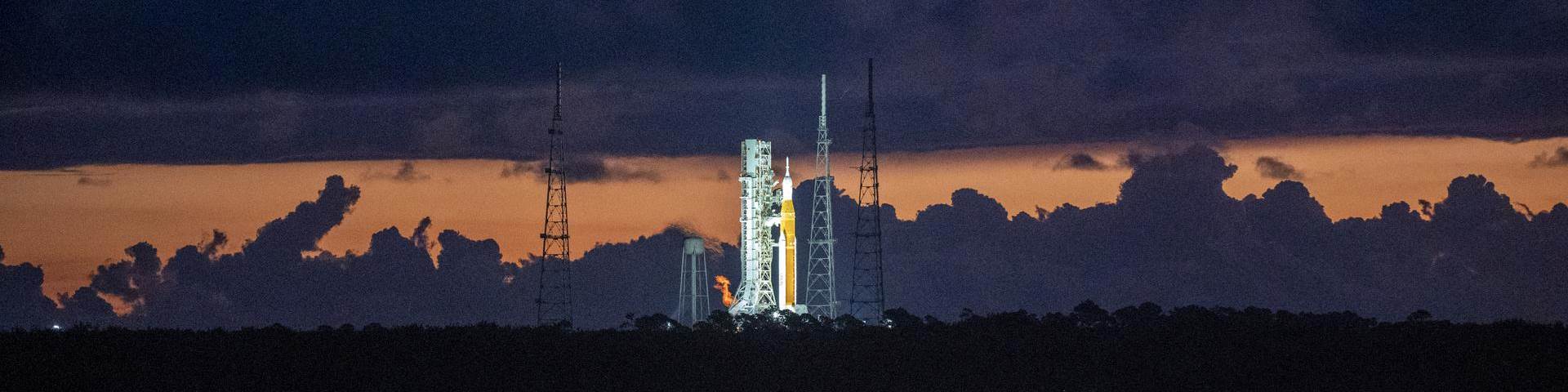

I know. But I want to talk about the NASA Artemis program because the Artemis I is supposed to launch on August 29. So it will most likely have launched by the time you're hearing this, there are some backup dates in case something goes wrong. So most likely it will have already launched by the time you're hearing this but in case you're not familiar, Artemis is a NASA program with the ultimate goal of sending humans back to the moon and exploring the possibilities of a sustained human presence on the moon. So this is the first mission of the whole program. And according to NASA, the goal for Artemis I is to demonstrate Orion the space capsule systems in space flight and test the reentry descent splashdown and recovery prior to a crewed flight. So this is an uncrewed flight, it's going to launch from Kennedy Space Center, orbit the moon for a little bit and then come back to Earth. And this is a big deal because this is the first time NASA will be launching the Space Launch System rocket, which is the most powerful NASA rocket to date. And the Orion spacecraft, both the SLS and the Orion capsule have 3D printed parts. And we can discuss those a little bit later in the segment.

Stephanie Hendrixson

Yeah, so I've been following Artemis, like I think a lot of people have, it's really exciting to think that we're gonna go back to the moon. And we're gonna do some different things on the moon than we have previously, like actually, maybe building habitats and trying to use the moon's resources in different ways. So I think this is a really timely moment to be talking about 3D printing in space, not only for things like Artemis that are on their way to space and things that are already out there. But to give a little bit of a futuristic look at how 3D printing might be used in the future. So earlier this year, I sat in on the Excellence in Space seminar had two additive industries for organizing that it was a virtual event, about a half day or so of different presentations. And it was super interesting, just all different ways that additive manufacturing, and space applications go together.

Julia Hider

Yeah. And from this event, you put out an article with six reasons space exploration, we'll need additive manufacturing. So do you want to, you know, go through this listicle and discuss some of the examples?

Stephanie Hendrixson

Yeah, sure. My very first example is really appropriate, getting vehicles to space. So that's exactly what we're seeing with Artemis right now. Additive manufacturing is allowing for assemblies to be consolidated, which means you you have fewer points of failure. We're seeing people introduce really innovative ways of like cooling engines and new materials. You know, one of the speakers at this event talked about how 10 years ago, there were only 12 launch companies, only 12 companies trying to figure out the the way to get vehicles and resources and things into orbit and further out into space. Today, there are more than 320. And I think a lot of them are using additive for for these reasons.

Julia Hider

Yeah, I went back and looked through the Additive Manufacturing Media site. And I found a couple of examples of 3D printed parts that are specifically on the SLS, which is sort of an unfortunately named rocket for people in 3D printing, because when I google SLS 3D printed parts, you just get selective laser sintering instead of Space Launch System. But anyway, I was able to come up with a couple of articles that we've written about 3D printed parts on this rocket. The first part is called a pogo actuator assembly. It's a vibration damping device that absorbs the shocks that are caused by blasts of propellant between the engine and the vehicle. So it's, it's an important part. And there are two components to this part, the pogo accumulator and the pogo z-baffle and together they kind of look like metal balloons, I guess. Aerojet Rocketdyne 3D printed these parts using powder bed fusion machines from us and concept laser. They have 3D printed and you know, both of the components. But just looking at the pogo accumulator, they've eliminated more than 100 welds and reduced costs by nearly 35%. And production time by more than 80%. So huge benefits like you were talking about.

Stephanie Hendrixson

Yeah, so another example that we've covered on our site. This was actually an episode of The Cool Parts Show, Masten Space Systems was working on the Broadsword engine. And so we had the combustion chamber for the engine here in the studio, and this is another case where like, this chamber would have been hundreds parts assembled together, they were able to 3D print it just in three parts. And by going to 3D printing, it actually allowed them to use a different material. So it was a metal matrix composite, basically aluminum that had this ceramic fill in it. So they got like all the lightweighting benefits from the aluminum material, but also the heat resistance and thermal performance from the ceramic. So those are some instances for launch vehicles. The next way that we're seeing 3D printing being used for space applications is to make systems that are going to be used in space. So things like satellites, rovers, the perseverance rover that landed on Mars has multiple 3D printed parts and assemblies on it. And I think you mentioned earlier the Orion capsule that also has some 3D printed parts.

Julia Hider

Yeah, there's another part from Aerojet Rocketdyne but these parts are for the reaction control system that control this spacecrafts roll, pitch and yaw. The original design was for the Apollo program. So it's pretty old. So they wanted to update it for Artemis, they were looking to reduce the number of engine parts and therefore increase the reliability make assembly and service easier or decrease costs, and just improve overall part performance. So they also wanted to redesign it to use new types of rocket fuel. So they used entomology to optimize the design, and they printed it on a fellow 3D printer. So the new RCS thruster is 1/5 mass, half the size and 1/3 the cost of a conventionally manufactured version. And because of the assembly consolidation, there is a reduced chance of failure during operation, which is a good result.

Stephanie Hendrixson

Yeah. So 1/3 the mass and half the size, like that's huge, because anything that you're going to get to space, like you want it to be like as lightweight, and as small as possible. So you can fit more into your payload and lots of really good benefits for making the things that we're trying to launch smaller and more compact with 3D printing. Now I want to get a little bit closer to the futuristic applications like things that we're seeing kind of in their infancy, things that are coming. So one example would be producing spare parts in space. So it's hard to anticipate everything that might go wrong, every tool or item that you might need. And so there are folks working on how do you produce things with a 3D printer in space that you might need. There's a company based in Florida called Made in Space, they've developed a couple of different printers that can work on the space station. They had a case study a couple of years ago, where they sent a wrench design file to the space station, and it was printed on the printer in orbit and was was usable. So that's an example of like extreme distributed manufacturing where the design is taking place on earth. And the files are getting sent and produced actually in space.

Julia Hider

Yeah, this was I was looking this up. It's a really interesting example. Because I've always wondered like, what are the effects of microgravity on 3D printing? And can you 3D print metal in microgravity? So they're exploring all of that, I think it'd be really interesting to see.

Stephanie Hendrixson

So yeah, there there are challenges with printing in space that various groups are working through. There also might be advantages, though. So that's kind of our next point, like there are organizations looking at can we manufacture products for Earth in space, because it's easier to do that. So one example this is not a 3D printed example. But like fiber optics, like certain types of fiber optic cables can be more easily manufactured in low Earth orbit than they can be on Earth. I've heard people talk about different things like like certain medications, like pharmaceutical applications, different types of chemicals, maybe can be produced more easily in space. And I'm sure we might find that there are some benefits to 3D printing without being held down by Earth's gravitational pull so much. Maybe we can use space to 3D print things advantage in the future.

Julia Hider

Yeah, this was absolutely crazy for me to think about, like you could have a factory in space, maybe in the future will be going on shop visits in space. Oh my gosh, and I call dibs on the first shop visit in space.

Stephanie Hendrixson

Absolutely. But also on that note, like making products in space, one of the big things that we might end up making is habitat like places for astronauts to live and work. I'm not sure if we'll call them astronauts if they're based on on the moon or some other place. But I know there are various projects kind of looking at this. One is called Moon to Mars planetary autonomous construction technologies or impact. And basically what they are hoping to do with the Artemis mission is figure out can we print like a structure that astronauts could live inside using the moon's regolith? So we're seeing lots of construction applications here on Earth where people are experimenting with trying to use the soil in the location where they're printing, and this is basically taking that same idea and applying it to the moon, and maybe applying it to Mars and other planets in the future.

Julia Hider

Yeah, this is another application that's just wild to think about. out, you could be living on the moon in a house made out of the moon.

Stephanie Hendrixson

But yeah, like it all kind of comes back to like that whole payload question like it would be so expensive to ship concrete to space. And so difficult, like, why not try and use the resources that are already there, I think a lot of what we're seeing with space is going to just amplify trends that we're already seeing on Earth. So distributed manufacturing with sending files back and forth. And then like extremely localized manufacturing by using the materials that are available. And then the the final point kind of along with that is outfitting those habitats. If people are going to live on the moon, even for just a short time, they're going to need furniture, like they're going to need a place to sit down, they're going to need a bed, if they're doing experiments, they're going to need lab equipment, they're going to need different instruments and things like that. And 3D printing could be a solution for that as well. Again, it's easier to ship raw material than it is to ship a completed table. And maybe you would find a way to use the resources that are already there in space to your advantage.

Julia Hider

So yeah, there's a lot of ways that space is using 3D printing right now and a lot of potential applications in the future.

Stephanie Hendrixson

Yeah, so we will put links to everything that we talked about in the show notes. So we are recording this before the Artemis launch, we anticipate that by the time you're hearing it, it will have launched. But this is going to be our last episode before IMTS before the International Manufacturing Technology Show.

Julia Hider

Yeah, we've been doing a lot of preparation ahead of the show. And it's almost almost here.

Stephanie Hendrixson

Yeah. So if you are a fan of AM Radio, we're actually going to be doing a live recording at the show. So if you're at IMTS on Friday, come over to the AM4U stage that's going to be in the AM pavilion in the West Building at 3 p.m. On Friday, we're going to be recording a conversation, me, Julia and our colleague Pete Zelinski on our observations from a week of IMTS. So it's going to be a good opportunity to catch up on additive news you might have missed. You can meet us if you come by and that episode will be coming out shortly after the show. So if you're not there in person, you'll be able to hear it after the fact Yep, should be exciting. So hope to see you there. If you'd like to show please subscribe to AM Radio on your favorite podcast platform give us a five-star rating. Tell a friend tell a colleague, a co-worker, somebody who might be interested about the show and thank you for listening.

Julia Hider

AM Radio is recorded with help from Austin Grogan and Seth Cooper. The show is edited by Alex Lytle and Stephanie Hendrixson. Our artwork is by Kate Bilberry. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in Cincinnati, Ohio. I'm Julia Hider. Thanks for listening.

Related Content

Zenith Tecnica Manufactures 3D Printed Hardware for NASA Psyche Mission

The node components designed by Maxar Space Systems were well suited to the advantages of EBM AM due to their complex geometries.

Read MoreEOS, Hyperganic Partnership to Elevate Space Components

Integration of Hyperganic Core, an AI-powered engineering software platform, with EOS’ digital additive manufacturing solutions aims to advance the space propulsion field.

Read More6 Reasons Space Exploration Will Need Additive Manufacturing

There are at least half a dozen ways 3D printing will contribute to space travel, research and habitation — and in some cases it already is. Insights from seminar focused on manufacturing challenges for the space sector.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

Space Launch System Accumulator is a Giant Leap for 3D Printing

A collaboration between Aerojet Rocketdyne and NASA is resulting in critical parts being 3D printed for new versions of the workhorse RS-25 engine.

Read More6 Reasons Space Exploration Will Need Additive Manufacturing

There are at least half a dozen ways 3D printing will contribute to space travel, research and habitation — and in some cases it already is. Insights from seminar focused on manufacturing challenges for the space sector.

Read MoreTo the Moon and Beyond with Additive Manufacturing

Aerojet Rocketdyne uses metal 3D printing technology from Velo3D to make a critical flight component lighter, smaller, and much less expensive than its predecessors.

Read More