Tooling

3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

Read More3D Printing Enables Mold Shop to Rapidly Prototype Medical Parts (Video)

A case study involving Mantle’s 3D printing technology allowed moldmaker Westminster Tool to go from design to injection molded prototype medical parts in three weeks.

WatchHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreThermwood LSAM 510 Additive Printer Useful for Molding, Tooling

RAPID 2022: Thermwood’s LSAM 510 additive printer features a single fixed gantry and a 5 × 10 ft. moving table with a 4 ft. maximum print height and a maximum temperature of 450°C.

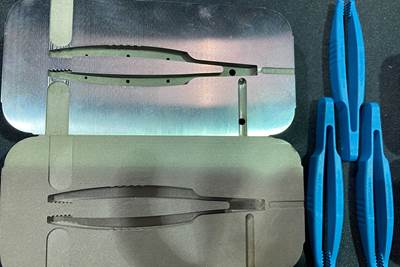

Read More3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

ListenHow to Improve Polymer AM Productivity 20X

A fast cycle time is critical to efficient production 3D printing, but it’s not the only thing. How you choose the right parts for AM, prepare jobs for production, and manage post processing will have just as big an impact on total 3D printing throughput. It all needs to work together to achieve maximum productivity.

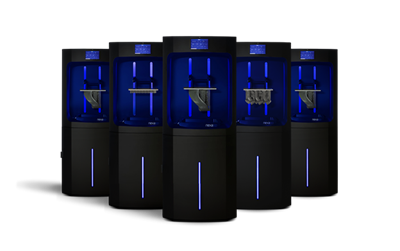

WatchMicro 3D Printer Complements Micro Moldmaking Capabilities

For micro mold provider Accumold, the Nano Dimension 3D printer provides a way to produce micro-scale prototypes and rapid tooling.

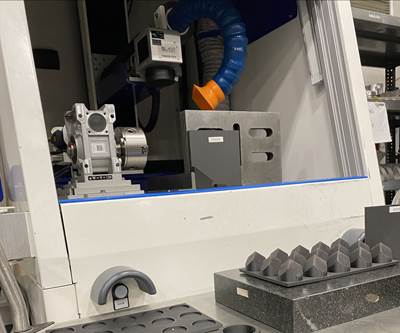

Read MoreFor Automated Machining Business, 3D Printing’s Value-Add Keeps Adding Up

Through robot grippers, assembly aids, custom kits and coolant hardware, additive manufacturing impacts every stage of production.

Read More3D Printing Reduces Time, Cost of Building Molds for Composites

Massivit 3D’s cast-in-motion technology uses a 3D printed gel to expedite production and lower costs associated with making molds for large, fiber-reinforced composite parts.

WatchReshoring, Tooling, Sustainability and More: Top 10 Stories of 2021: AM Radio Episode #9B

Reviewing our most-viewed stories of the year revealed some of the topics that have been top-of-mind for additive manufacturers. Read or listen to the countdown.

Listen