LFAM

10 Trends from Formnext 2021

The largest trade show for additive manufacturing technology returned with an in-person format this November. Editors Peter Zelinski and Stephanie Hendrixson share sights and trends from the event.

WatchABB Introduces Software Capabilities to Simplify Robot Programming for AM (Includes Video)

Slicer software output can be converted to a robot program. The user chooses speed and precision of printing, but no specialized knowledge of robot 3D printing is needed.

WatchFormlabs Launches Postprocessing Form Wash L, Form Cure L

The automated, postprocessing machines provide users with a streamlined workflow for large-format 3D printing.

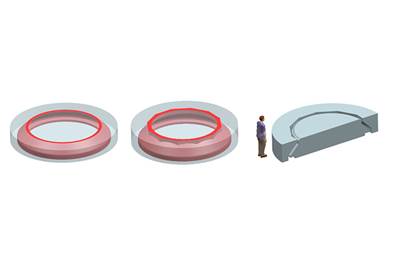

Read MoreFor Sustainable 3D Printed Architecture Think Renewable, Not Permanent

The design choices of today won’t be the trends of tomorrow. Aectual chooses to embrace changing tastes by making it easy to procure and recycle 3D printed architectural elements.

Read More3D Printing at the Turn of Iten’s Century

This specialist in laminates, composites and plastics manufacturing will turn 100 years old in 2022. 3D printing in polymer will be part of the company’s next hundred years, leadership says.

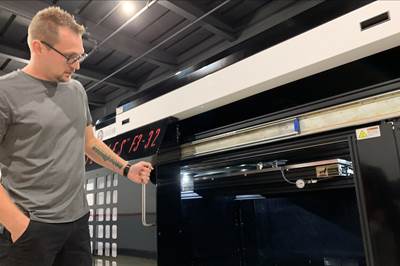

Read MoreMVP Updates Large-Scale Thermoset Composite AM System

The RAM 48 has a print area of 4 ft. × 8 ft. with modular, expandable 4 ft. × 4 ft. sections to enable custom build dimensions.

Read MoreAirtech’s Dahltram Resins Approved for Use on All Thermwood LSAM 3D Printers

The company says its Dahltram range of resins are suitable for multiple print platforms, providing production flexibility with end-use material validation.

Read MoreThe Way Ahead for Wire Arc Additive Manufacturing

Tooling today, production tomorrow. The capability will advance as value is increasingly seen in lead time savings and design opportunities. Parts that today are cast offer a particularly promising application for a process that is “welding, except not.”

Read MoreFlight Simulator Made Through Large-Scale 3D Printing: The Cool Parts Show #33

Our biggest cool part so far! Printing this massive structure in one piece saves cost and time for L3Harris.

WatchResearch Partners Building World’s Largest Sand Binder Jetting Printer

3D printing provides flexibility to produce large turbine components near offshore wind projects, lowering transportation costs and offering environmental benefits.

Read More

.png;maxWidth=300;quality=90)