LFAM

EOS Partners with Morf3D in Applied Digital Manufacturing Center

The center is designed to harness applied research, advanced engineering and application development, serial production and industry partnerships to drive the industrialization of digital manufacturing in high-growth markets.

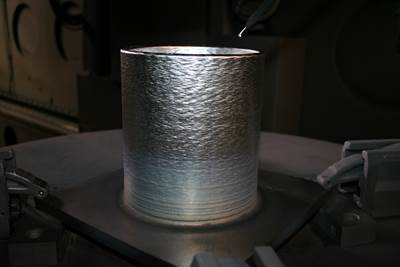

Read MoreAI to Aid Consistency in Electron Beam Additive Manufacturing

Machine vision and algorithms have helped EBAM users address problems as they occur in deposition, but AI could be able to predict problems before they happen.

Read MoreBigRep’s Shield Large-Format Dry Cabinet Prevents Material Degradation

Cabinet is designed to protect filament from material degradation by eliminating more than 99% humidity, thereby reducing material waste by 20% and repair costs up to 50%.

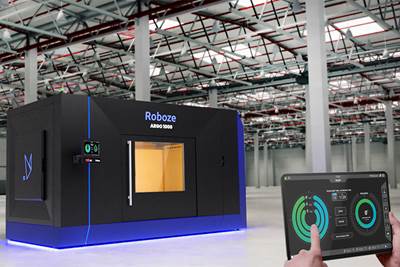

Read MoreRoboze’s ARGO 1000 Fabricates Large Parts Using Super Polymers, Composites

Printer uses more sustainable, high-performing super polymers and composites such as PEEK, Carbon PEEK and ULTEM AM9085F to reduce the strain on global supply chains.

Read MoreThermwood, Boeing, Navy Collaborate on Large-Scale Composite Tooling Research

Thermwood’s large-scale additive manufacturing (LSAM) machine was selected as the large-format additive manufacturing (LFAM) machine to conduct the technology development.

Read MoreMeet the LSAM Additive Printer

Thermwood Corporation, manufacturer of some of the largest composite thermoplastic additive manufacturing systems operating in industry today, has announced the availability of a new line of lower cost "print only" LSAM systems, called LSAM Additive Printers. (Sponsored)

Read MoreFarsoon’s FS721M Large-Frame Metal 3D Printer Offers Dual, Quad Laser Options

The printer is designed for high-volume series production, and includes features and capabilities to help ensure quality and repeatability, including high-performance, fully digital optics for controlling the lasers.

Read MoreThermwood Releases ‘Why LSAM’ Video for Large-Part Production

Video focuses on large-scale additive manufacturing systems (LSAM) for thermoplastic composite large-part production.

WatchA Resonant Harmony for Bell Casting and 3D Printing

When a 180-year-old bell foundry sought an alternate solution for expensive metal mold patterns, it turned to a 125-year-old company for a modern solution: large-format additive manufacturing.

Read MoreDigital Demo: Why LSAM?

Scott Vaal, Thermwood’s LSAM product manager, offers an overview of key aspects of the large scale additive manufacturing market. (Sponsored)

Read More

.png;maxWidth=300;quality=90)