Volkmann vLoader Automatically Transfers Metal Powders to 3D Printers

The conveyor ensures continuous flow of powders to 3D printers for consistent, unattended production.

Share

Read Next

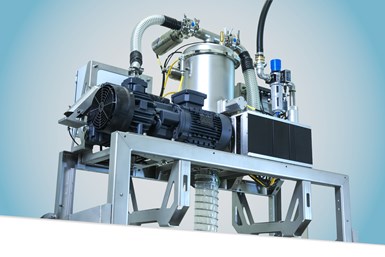

A Volkmann vLoader metal powder conveying system installed atop a 3D printer. Photo Credit: Volkmann

Volkmann’s vLoader metal powder conveyor applies the company’s signature vacuum conveying technology to assure a continuous flow of powder to one or more printers for consistent, unattended production without interruption, 24/7.

The vLoader metal powder conveyor can be installed directly on top of a 3D printer to automatically transfer metal powders from a bulk storage container, glove box, buffer hopper, reusable powder reprocessing system or other powder source through piping or hose and then gently discharges the powder into the printer’s supply hopper.

Automating the cumbersome, manual powder transfer process, the vLoader operates in a sealed system with a closed loop approach that eliminates the potential for worker exposure to toxic metal materials and safeguards the sensitive materials from contamination due to exposure to the work environment.

The metal powder loading system is suitable for integration with most 3D printers, operates in both normal air environments and under inert conditions, and may be retrofit onto printers in the field.

The powder conveyor is offered with the company's companion vDryer vacuum dryer as an option to automatically restore metal powders to a targeted moisture content value. Custom configurations for any additive manufacturing process are also available.

Related Content

-

Formlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

-

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.