Teton’s SmartSlice Reduces 3D Material Usage

Software can automatically optimize parameters so users can identify settings that yield the fastest print job by minimizing time and material while meeting strength requirements.

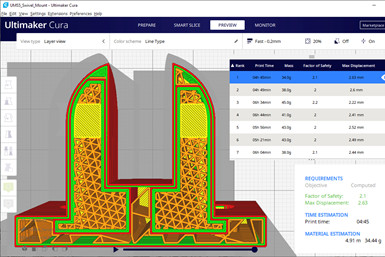

Teton Simulation’s SmartSlice software

Teton Simulation’s SmartSlice brings engineering-grade part simulation to Cura as a plug-in for Ultimaker Essentials users. Smart Slice is designed to reduce print times and material usage by optimizing print settings to ensure parts meets end-use requirements before parts are printed.

SmartSlice software creates the iterations virtually. Using the integration options of Cura’s open and pluggable platform, SmartSlice ensures that parts meet engineering criteria before printing, saving time and materials. Smart Slice is also well suited for replacing broken components to accelerate tool replacement, helping to get production back up and running quickly.

The company says that SmartSlice is easy to use and is extremely fast. It enables manufacturing engineers or machine operators to quickly iterate using the software rather than print unnecessary, wasted parts. Additionally, SmartSlice can automatically optimize parameters so users can identify settings that yield the fastest print job by minimizing time and material while meeting strength requirements. The technology also gives 3D printer operators near instant feedback on the viability of projects. Plus, the optimization feature takes the guesswork out of determining the right slicing parameters.

Related Content

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.