Massivit 10,000 Additive Tooling System for Composites Manufacturing

Rapid + TCT 2022: The system utilizes the the company’s Cast In Motion technology, which is said to enable direct printing of complex molds using high-performance casting materials.

Share

Read Next

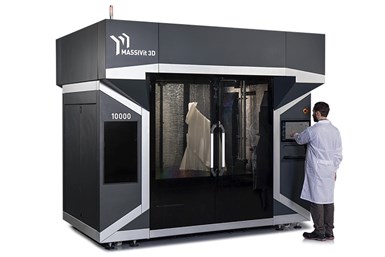

Massivit 3D’s 10,000 additive tooling system. Photo Credit: Massivit 3D

Massivit 3D’s 10,000 additive tooling system is designed to overcome bottlenecks in composite materials manufacturing. Based on the company’s Cast In Motion (CIM) technology, the system is said to enable direct printing of complex molds using high-performance casting materials. The technology is said to shorten tooling production time by 80%, reduce costs and decrease material waste associated with traditional tooling methods.

In addition to facilitating direct printing of molds, the enables fast production of complex prototypes, mandrels and plugs, the company says. The system is also said to empower composite fabricators to digitally produce complex, custom molds within a matter of days, instead of weeks. The CIM technology is said to combine ultrafast, additive manufacturing (AM) with high-performance, thermoset casting materials to enable automated tooling for composites.

It is said large tools and molds traditionally used for producing fiber-reinforced composite parts can be expensive, slow-to-build, wasteful and require extensive manual skilled labor. The 10,000 is said to offer market time- and cost-saving benefits for the manufacturing of large tooling, including simplified production and higher yield, simplified supply chain and reduced required stocks, and reduced waste of expensive materials.

The system process begins with an outer, sacrificial shell 3D printed with a water-breakable gel using Massivit 3D’s Gel Dispensing Printing Technology (GDP). A thermoset epoxy material (which is said to have high mechanical and thermal properties) is cast into that shell, forming an isotropic mold. Once the 3D printed tool is immersed in plain water, the sacrificial shell crumbles away, leaving the desired mold, ready to use.

Technical advantages are said to include design freedom which enables allows mold production of function-oriented, intricate geometries. The system is said to enable better and faster tool design cycles, including many features to reduce iterations. The CAD part to CAD mold design is said to enable improved accuracy, consistency and higher reliability. Users are also said to achieve true isotropy as well as high mechanical and thermal properties at elevated temperatures.

Related Content

-

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

-

In Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

-

Southern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.