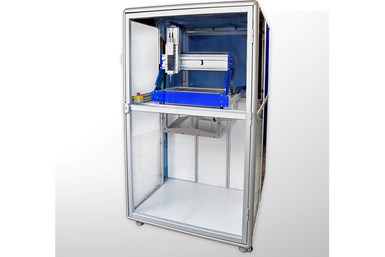

Chromatic RX-Flow 3D Printers for Reactive Extrusion Additive

RX-Flow printers are a low-cost option for manufacturers interested in testing and implementing industrial 3D printing with more durable, flexible materials than are available with FDM, SLA and other 3D printing technologies.

Share

Read Next

Chromatic 3D Materials’ RX-Flow line of 3D printers provides users with reactive extrusion additive manufacturing (AM) with thermoset polyurethanes. Designed for development work and low-volume industrial production, RX-Flow printers are a low-cost option for manufacturers interested in testing and implementing industrial 3D printing with more durable, flexible materials than are available with FDM, SLA and other 3D printing technologies.

Chromatic’s RX-Flow printers are based on the company’s RX-AM materials and technology platform specifically designed for 3D printing thermoset elastomers such as 2K polyurethanes. The printers include control systems and instrumentation designed for printing with Chromatic materials and software.

The company is offering monthly technical service subscriptions for purchase with each printer. Materials available for purchase include printable polyurethanes with Shore A hardness ranging from 50 to 90. Chromatic also provides custom materials with a variety of colors, hardness and special properties such as antibacterial, static discharge, biocides and more.

“There are many manufacturers who want to test drive 3D printing with thermoset engineering materials, but find industrial 3D printers cost-prohibitive,” says Dr. Cora Leibig, Chromatic 3D Materials CEO. “Our new line of R&D printers gives them a budget-friendly way to demonstrate proof of concept and take their first steps toward industrial-scale 3D printing with new technologies like reactive extrusion additive manufacturing.”

Chromatic offers R&D printers in two sizes: the RX-Flow 3500 which is 18.9" × 29.3" × 7.63" (479 mm × 743 mm × 194mm); and the RX-Flow 7000 which measures 26.75" × 41.1" × 7.63" (680 mm × 1040mm × 194mm)

The printers can produce up to 800 g/hr. Features include a T-track aluminum table and lead screw drive system. The printers carry a CE mark. Bespoke printers for larger volume industrial production are available on request.

- Learn more about Chromatic 3D Materials developing tough and flexible thermosetting urethanes for additive manufacturing. The resin formulation is only part of the path to scale.

- Chromatic also offers smooth-mode technology for 3D printing durable rubber parts.

Related Content

-

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.