What Is Material Extrusion 3D Printing?

Material extrusion extrudes material through a nozzle and selectively deposits it layer-by-layer to form an object. After three decades of material advancements and a diverse array of start-ups and applications, the use cases for this technology are still going strong.

Material extrusion was the second of now seven AM processes to reach the market and see commercial success. Thanks to material advancements and a diverse array of start-ups and applications, material extrusion is still driving a lot of excitement three decades after its introduction.

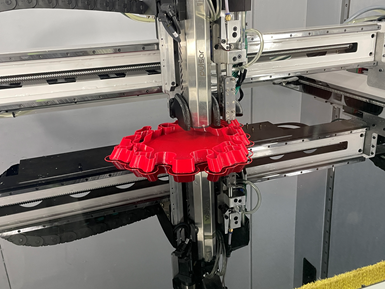

Material extrusion 3D printers range from desktop machines all the way to large-format printers big enough to stand inside. Recently, "medium" format printers like this one from Cincinnati Inc. have become more prevalent.

As the name implies, material extrusion extrudes a material through a nozzle (or orifice) and selectively deposits material layer-by-layer to form an object. Material extrusion is kind of like squeezing toothpaste out of the tube, except that plastic hardens a lot faster after it is extruded and cools down.

What is used in material extrusion?

Most material extrusion systems use a spool of plastic filament as the feedstock, which costs about $20/kilogram for standard materials (PLA, ABS, PC, etc.). Proprietary filaments can be 2-3 times more expensive, and advanced materials (nylon, flexible filaments, carbon fiber reinforced filaments, etc.) can easily run $40/kilogram or more. The systems themselves can cost less than $1,000 for an entry-level system for home use to $5,000-$10,000 for a desktop system for prototyping and tooling to $150,000 and higher for industrial-grade systems.

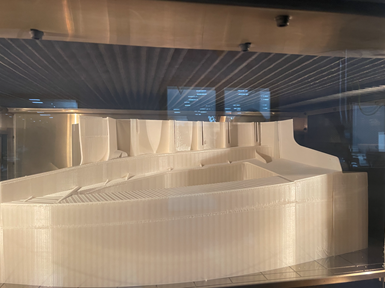

The most familiar type of material extrusion is likely desktop FFF as seen here. (But interestingly, the two printers pictured are being powered by a hydropower turbine featuring parts printed with BAAM, a large scale version of extrusion.)

Industrial-grade systems offer faster build rates and larger build volumes. Some large-scale industrial systems come equipped with pellet feeders, which increases material feed rates even more dramatically. Pellets can also be bought in bulk for about 1/5 the cost of filament, and it is easy to add chopped carbon fiber, for instance, to pellet feeders to improve strength. Big Area Additive Manufacturing (BAAM), a material extrusion technology developed by Oak Ridge National Labs and machine tool manufacturer, Cincinnati Incorporated, used this capability to additively manufacture a full-scale vehicle chassis in days. They have since claimed the Guinness World Record for the largest solid 3D printed object, namely, a wing trim-and-drill tool for Boeing. Local Motors, which ceased operations in 2022, used BAAM technology to additively manufacture the chassis for Olli, a small commuter bus that is easily customized for different municipalities. It went on to use Thermwood’s large-scale additive manufacturing (LSAM) technology to 3D print 90% of the vehicle.

Video: See material extrusion in action in this episode of The Cool Parts Show, featuring an autonomous underwater vehicle made with BAAM.

Material Extrusion Printers: Click here to view suppliers

The History of Material Extrusion

Material extrusion was invented and patented by Scott Crump in 1989 and introduced to the market as Fused Deposition Modeling (FDM) by Stratasys, the company Crump co-founded. Stratasys popularized the use of FDM in a variety of industries. Given FDM’s capability of additively manufacturing prototypes, concept models, tooling/fixtures/jigs and more in a variety of different plastics, Stratasys, at the time, became the dominant player for material extrusion systems (much like 3D Systems did for vat photopolymerization as discussed last month). In fact, FDM became synonymous with material extrusion the same way many people ask for a Kleenex instead of a facial tissue.

As key patents started to expire, material extrusion technology was embraced by the open source community, giving rise to FFF (fused filament fabrication) systems and eventually RepRaps, 3D printers that could replicate themselves. This open source revolution spawned hundreds of material extrusion start-ups, mostly notably MakerBot, which was acquired by Stratasys for over $400 million in 2013 (check out the documentary, Print the Legend if you want to learn the full story). While this acquisition frustrated many in the open source community, the next wave of the AM revolution was launched and remains strong to this day thanks to new startups and new capabilities.

What are the pros and cons of material extrusion?

Extrusion 3D printed parts have applications including tooling, consumer goods and aircraft parts.

Despite these advances, material extrusion does have its drawbacks. First, it is a lot slower than injection molding — parts can take hours (or sometimes days) to build versus seconds. On the plus side, material extrusion does not require any molds or tooling to fabricate a part. This why cost tradeoff curves for AM show a flat line for material extrusion as the production quantity increases compared to the decreasing slope when using injection molding. Thus, a good use case for material extrusion arises when production volumes are low and tooling costs are high. This is why companies like Airbus, Boeing, Lockheed Martin and others additively manufacture complex ductwork components using ULTEM 9805, one of the few FAA-certified polymers for material extrusion. Meanwhile, countless machine shops are finding use for consumer-grade material extrusion systems to make custom fixtures and jigs and improve production efficiency, and the costs of these desktop systems are so low that companies can break-even in as little as 1-2 months. It has never been as easy to make the business case for one of these systems as it is today.

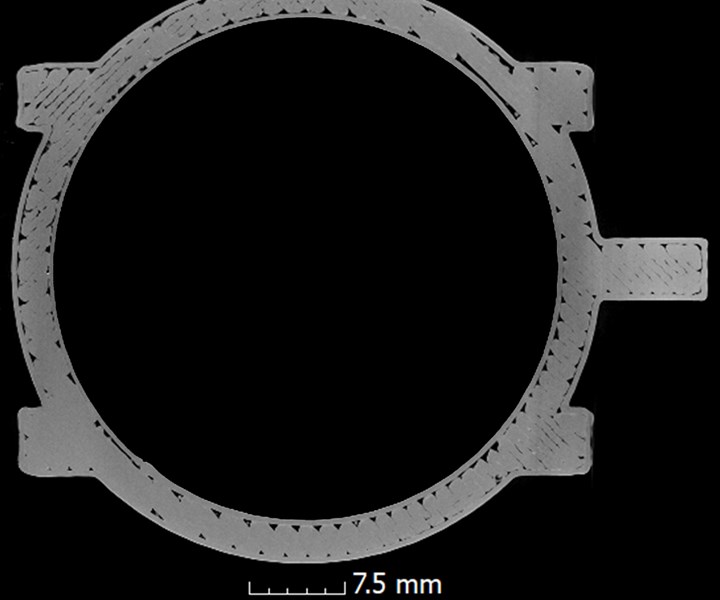

A computed tomography (CT) scan of the inside of a part made via material extrusion shows how deposition strategy (e.g., toolpath, contour, road width) affects the infill and density.

Photo Credit: Timothy W. Simpson

Another big drawback of material extrusion is part strength. Parts made by material extrusion are not fully dense (see the image above), and anisotropy arises due to layer-by-layer fabrication. The latter occurs because the “weld strength” between layers is not as strong as the strength within a layer due to the way that polymers gain strength during processing. Injection molding techniques are fully dense and do not suffer from this anisotropy because the entire plastic part is heated and pressurized in the mold during fabrication. This leads to stronger parts via injection molding, but process improvements along with a better understanding of the impact of different process parameters are slowly closing this gap. Meanwhile, advancements in the technology, combined with new material feedstocks, are enabling the use of carbon fiber, Kevlar and even metallic particles to be embedded in filament and additively manufactured with material extrusion. This is game-changing for material extrusion.

Related Content

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MoreRead Next

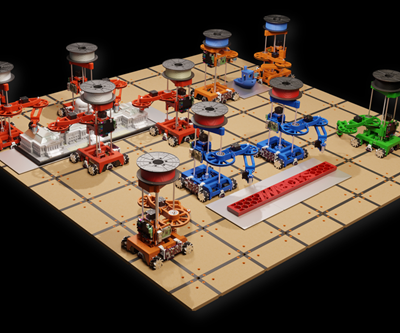

Robots, Assemble! A New Path to Autonomous Mobile 3D Printing

Robot swarms may sound alarming, but research at the University of Arkansas reveals that they may enable a new, ultra-efficient era of automated manufacturing and 3D printing.

Read MoreWhat Is Vat Photopolymerization?

Vat photopolymerization was the first AM process to be successfully commercialized. Three decades later, this technology has shown how AM is capable of scaling to volume production and making custom products on demand.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More