Share

Read Next

One of the challenges with generative design is the computational power required. Additive manufacturing offers a means of realizing intricate geometries that are tailored and optimized to the set of performance conditions required for a specific need, but in applications optimized for a larger set of conditions, accessing and employing the cloud-based processing capacity necessary for iterative computations loops becomes a meaningful share of the cost of the capability.

Instead, what if there was an expert system that already “knows” the right or nearly right geometry for a given problem, so that no generative design and therefore significantly less computation is needed?

That aim is the promise that Ohio-based startup Voxel is working toward. The company recently moved into a new headquarters in Cincinnati where it will perform the 3D printing and physical testing to develop this system.

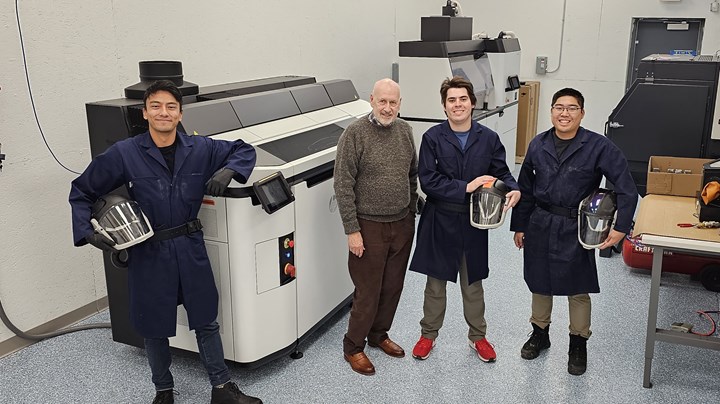

Voxel includes (left to right) Massimo Vancheri, finance and business operations, Robert Rothfuss, sales and marketing, and co-founders Zachary Beller, CTO, and Aaron Chow, CEO. Photo: Voxel.

Artificial intelligence (AI) replaces iterative computation in Voxel’s system. Co-founder and chief technology officer Zachary Beller says the system uses “an AI-enabled backend” to “relate physical performance to geometric parameters” in order to suggest a form that is “better than 90 percent of the way there” to being fully optimized for the input aims and requirements of the part. And all this comes without computation, without generation.

He offers the analogy of an I-beam. Beller says, “Engineers in construction don’t design I-beams. They specify them based on known performance of these shapes.”

The way I-beams are known, the Voxel AI will “know” the performance of an uncountable number of complex, organic, unnamed geometric forms.

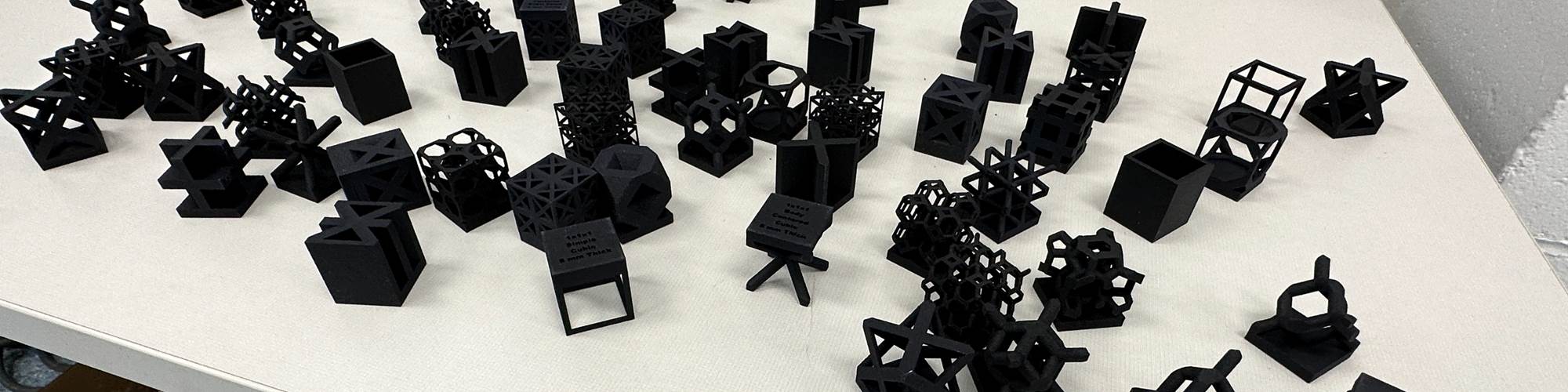

Testing stress and strain of many geometric unit cells (just a small sample seen here) provides the data that will allow its system to capably tailor forms for lightweighting applications.

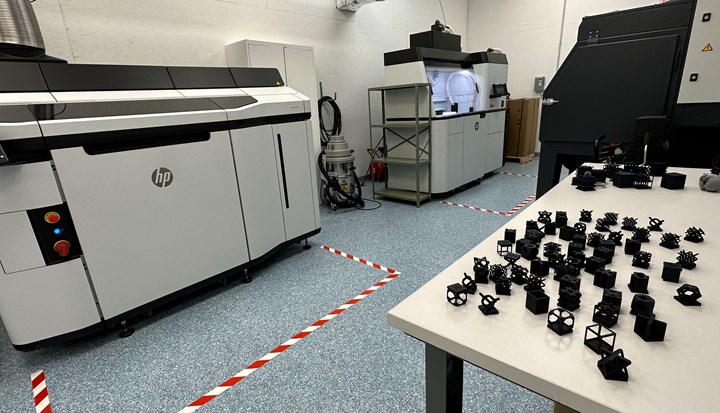

Building this tool means feeding the AI. That is a key purpose of the new facility. The Voxel team here is 3D printing small cubic unit cells in many different geometries (see photo) so that these geometric forms can be tested and the data can be applied to building the neural network AI system. Unlike OpenAI and its tool ChatGPT, Beller says Voxel will own all the data on which its AI is built.

Funding for the work comes from various sources. The company has venture capital investment. In addition, it performs AM consulting and prototyping work on its HP and Xact Metal machines using the design understanding it has developed so far.

The unit cell printing and testing work right now is being done in polymer. The company’s HP Multi Jet Fusion machine allows for 3D printing of just under 1,300 geometric unit cells like the ones seen here in a single build.

For the system it is developing, there is a long way to go, but work is straightforward. “For now, we are solving the lightweighting problem in polymer,” Beller says. Unit cell forms are being tested with this purpose in mind. That is, the geometry samples are being evaluated for stress and strain, one cell and one linear axis at a time.

Related Content

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreArtificial Intelligence and Additive Manufacturing Are Connected: AM Radio #36

Stephanie Hendrixson and Peter Zelinski discuss how AI and AM go together. There are already plenty of uses of AI in 3D printing for design, process planning and process monitoring, and the link will grow stronger as the “frictionlessness” of AI blends with that of AM.

Read More