Most powders for metal 3D printing are made up of particles of similar size, which ensures repeatable density and performance. But Uniformity Labs offers materials that are made up of particles in different sizes. These multimodal powders can pack more densely in the bed of a laser powder bed fusion or binder jetting 3D printing, leading to reduced porosity, more efficient use of lasers and binder, and even improved material properties.

Related Resources:

- How Uniformity Labs produces its powder and specific use cases

- How the company sees multimodal powders fitting into viable serial production (presented at RAPID)

- Recent materials introduced by Uniformity Labs: stainless steel for binder jetting, nickel alloy for laser powder bed fusion

- A different materials strategy that leans into uniform spherical powder particles

- Subscribe to The BuildUp, Additive Manufacturing Media’s newsletter on 3D printing for industrial production.

Transcript

What powder characteristics are most desirable for metal 3D printing?

There are more perspectives on this than you might expect. In many cases, additive manufacturers emphasize consistency. They want powders that are roughly the same size and spherical so that they flow well and behave predictably in 3D printing.

That preference actually has an impact on how materials are made. When powders are produced through gas atomization, molten metal is passed through a stream of high pressure inert gas to solidify particles in spheres in a range of different sizes. Those different sized particles are then separated out to be used in different applications.

That means that powder suppliers are often taking just a narrow selection or “cut” from every batch of powder to be used for things like laser powder bed fusion or binder jetting. Maybe just the particles that are in the range of, say, 15 to 40 microns in diameter. The rest of the atomized material might go into different applications, or it might get recycled or reused back into gas atomization.

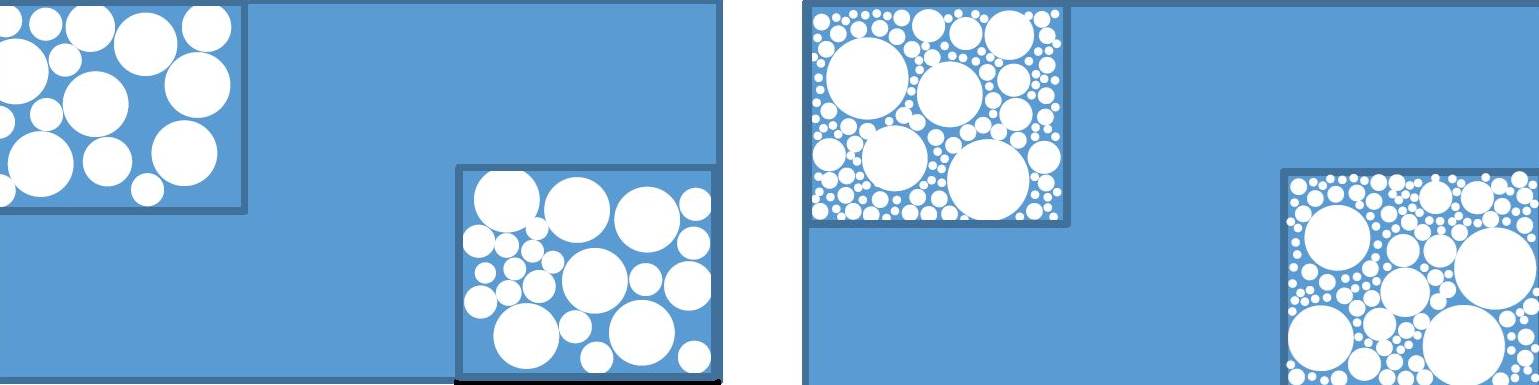

But I recently visited Uniformity Labs in Fremont, California, and learned about a different strategy that they are taking for producing additive powders. So instead of being made up of particles that are all roughly the same size, their materials are multimodal. They combine a range of different powder diameters. So a typical powder from uniformity labs might have particles ranging from 15 to 90 microns in diameter.

So right now the company atomizes about a third of its own material and then acquires powder from other sources as well. They then take multiple cuts from every batch and combine it together to make materials for metal 3D printing.

A big reason that this isn't really done is phase separation. So when you have a material that's made up of lots of particles that are different sizes and then you agitate them, say, in a sieve or a powder hopper, they can actually separate back out.

If you've ever taken a cereal box and shaken it and found that all the good stuff either rises to the top or falls to the bottom, that's phase separation. Usually the larger particles will rise and the smaller ones will fall.

So to make this work, Uniformity Labs has to take a few extra steps to ensure that their multimodal powders will stay blended.

Understandably, they didn't go into a lot of detail about how this works, but the short version is they use cycles of heating and cooling while they're blending the materials together to ensure a homogenous mixture.

Nothing changes with the chemistry of the material, but it becomes entropically inclined to stay blended. And that holds true all throughout sieving, printing, postprocessing, anything that this powder might go through in an additive manufacturing workflow.

Uniformity Labs has found that these multimodal powders offer some benefits for additive manufacturing because of the way they pack more densely together.

The particles are different sizes and so they randomly disperse to fill the powder bed. If you think of it another way, there are fewer and smaller voids between the particles.

So in laser powder bed fusion, that means without changing anything else, you can melt more material with every pass of the laser. There's simply more material there to be fused. But if you do change up your print parameters a little bit, you can take advantage of this. Run the laser faster, print thicker layers. You can even improve the material properties of your finished part.

Those smaller voids are also really beneficial for binder jetting as well. The particles are closer together and so the binder doesn't have to bridge as far between them. That means you can actually use less binder and end up with stronger green parts, which is really important when you think about how you're going to handle, de-powder and postprocess these really delicate green parts, especially if you're considering something like automated de-powdering.

There are also potential sustainability benefits here too. With multimodal powders you can run your printer more efficiently with less energy for laser powder bed fusion or using less of that glue or binder for binder jetting.

Multimodal blends also mean that you can use more of the powder that was atomized in the first place for additive manufacturing, potentially translating to less material waste overall.

If you want to learn more about multimodal powders and everything that I saw at Uniformity Labs, you can find a link to the full article in the video description below.

And if you're interested in more on additive materials and applications, check out The BuildUp. It's our twice weekly newsletter from the editors of Additive Manufacturing Media with original reporting and writing. We'll put a link to that in the video description as well. Thank you for watching.

Related Content

Safer Nuclear Energy: 3D Printed Silicon Carbide Fuel Forms

Binder jetting provides a way to create pure silicon carbide fuel structures that can withstand the harsh environment of a nuclear reactor and provide a strong barrier against the release of radionuclides.

Read MoreWhat Is the Role of Sintering in Binder Jetting? (Video)

And how strong are green parts prior to sintering? Filmed at HP, here is a look at sintering, including the shrinkage from green to sintered binder jet parts.

Read MoreAMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.

Read MoreSintratec Adds More Power in S3 Selective Laser Sintering System

Formnext 2022: The system comes with a 30-W fiber laser, which is three times more powerful than the Sintratec S2, resulting in shorter printing times.

Read MoreRead Next

Multimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

Read MoreGetting to a Circular Model for Metal Powders Makes AM More Sustainable

6K’s UniMelt process offers efficiency and control in the production of metal powders for additive manufacturing. But more than that, it is a home for unused and oversized powder, metal scrap and more that can close the loop on metals.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)