Dr. Kurt Terrani, the executive vice president at Ultra Safe Nuclear Corporation’s Core Division, was on the team that developed a process for 3D printing silicon carbide at Oak Ridge National Laboratory. USNC licensed the technology for use in making Micro Modular Reactors.

As we continue to feel the impacts of climate change, finding alternative sources of energy that don’t involve burning fossil fuels is an important part of reducing and mitigating its effects. Renewables such as wind, solar and hydro power can provide clean sources of energy, but they might not be able to provide enough power. Some scientists are now turning to nuclear as a promising source of power that doesn’t generate greenhouse gas emissions.

Many of the nuclear power plants in use right now were built in the 1950s and 1960s, and are scheduled to be phased out soon. Building new plants using the same outdated technology will require large amounts of land, money and time. So researchers have begun developing smaller, safer nuclear reactors that are enabled by advanced manufacturing techniques, including additive manufacturing.

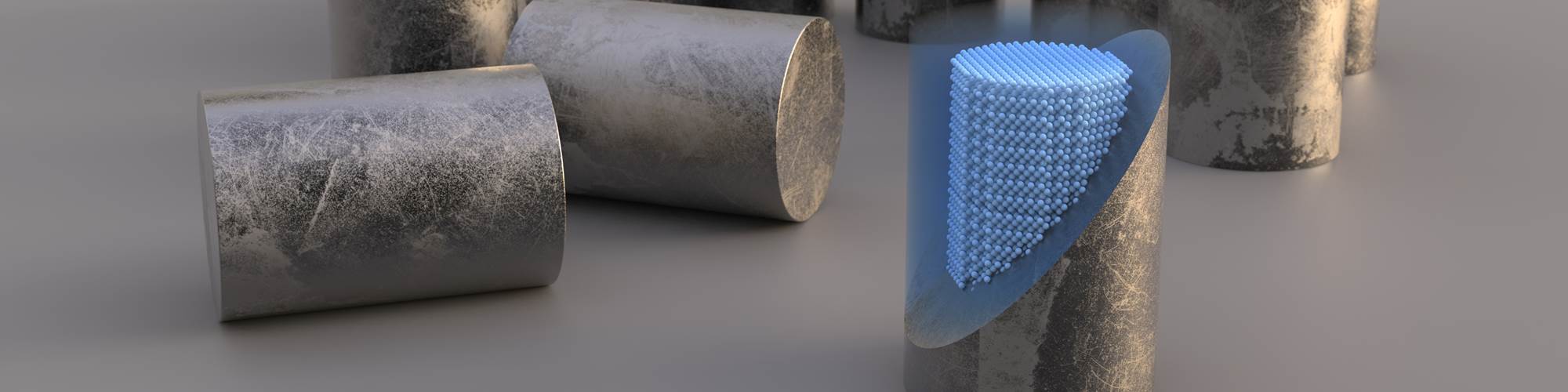

USNC’s Micro Modular Reactor (MMR) is designed to be safer, smaller and less resource-intensive than a traditional nuclear power plant. Photo Credit: Ultra Safe Nuclear Corp.

A Smaller, Safer Solution

Ultra Safe Nuclear Corporation (USNC) is a Seattle-based company that’s developing what it calls a Micro Modular Reactor (MMR). “The thing that's fundamentally different about our system is its small size and low power density,” says Dr. Kurt Terrani, Executive Vice President at USNC’s Core Division. Each MMR will generate 15-30 megawatts of heat or 5-10 megawatts of electricity. That’s much less than the 3,000 megawatts of heat or 1,000 megawatts of electricity that traditional nuclear power plants generate, but it’s still a lot of power. (A single MW is enough to power about 800 average U.S. homes for a year.)

The MMR will also be less resource-intensive than a traditional nuclear power plant. Because it’s smaller and inherently safe, it requires less land and a small emergency planning zone — Terrani estimates that it would have a footprint of less than 5 acres. It’s cooled by gas instead of water, doesn’t need an electrical grid or infrastructure support and requires fewer operators because it’s more autonomous. Once the fuel goes into the reactor, it runs for 20 years. “We want to have a reactor that we can deploy anywhere, so it can be deployed adjacent to a chemical plant, it can be deployed in the middle of a town to power homes, or it can be deployed in remote locations,” he says.

The MMR is also designed to be inherently safe. This is partially due to the lower power density. Terrani says that the more power a nuclear plant generates, the more dangerous it could be if something goes wrong. Traditional nuclear power plants have managed this risk with a “defense in depth” strategy that uses multiple safety systems. The lower power density and design of the MMR means less risk and less need to rely on safety systems.

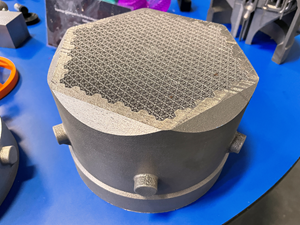

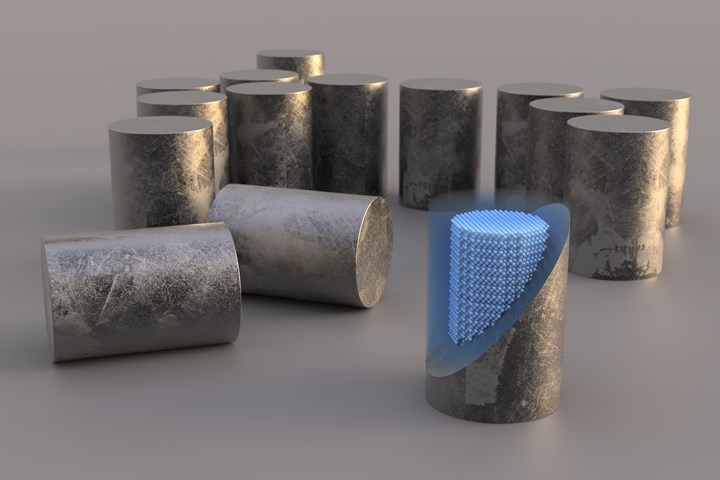

USNC uses a binder jetting process licensed from Oak Ridge National Laboratory to 3D print fuel structures from silicon carbide. The silicon carbide is strong enough to handle the harsh environment of a nuclear reactor and provides a barrier against the release of radionuclides. Photo Credit: Ultra Safe Nuclear Corp.

Printing Silicon Carbide

One of the key enablers of the MMR is a process for 3D printing silicon carbide, which Terrani helped develop while working at Oak Ridge National Laboratory, and which was licensed from Oak Ridge.

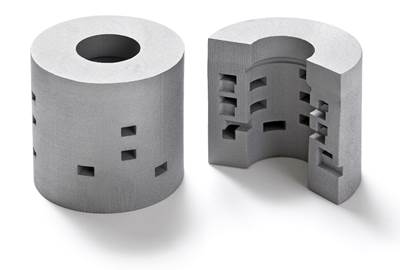

The 3D printing process is used to produce a silicon carbide form that holds nuclear fuel particles. Silicon carbide is a refractory material with exceptionally high temperature resistance and mechanical properties (for example, it’s used in tank armor, Terrani says). It also provides a strong barrier against the release of radioactive nuclides. These properties make this material a great fit for nuclear reactors, but they also make it extremely challenging to work with. It’s difficult to machine, and it requires very high temperatures to sinter. Silicon carbide often has other materials added to it to help it sinter, but this can affect its performance. “The trick for nuclear, and for a lot of demanding applications, even aerospace, is that you have to have really pure silicon carbide,” Terrani explains.

Binder jetting provides a much easier way to work with pure silicon carbide. “Binder jet printing is unique in the sense that it is somewhat agnostic to what you're printing,” Terrani notes. It can work with a range of powdered materials, even ceramics that are difficult to manipulate. Materials with high temperature resistance like silicon carbide are also a good fit for binder jetting, because the process takes place at room temperature.

Terrani says that the company has built up its process knowledge to find the right parameters for binder jet printing silicon carbide. It had to determine the type of powder, how it’s spread, the type and amount of binder, and drying time. Terrani says that USNC has worked to dial in the process, but it has found that the best process varies by location. “We have facilities in Salt Lake City, Utah and we have facilities in East Tennessee, and different parameters work for those different climates,” he explains. “There's different humidity.”

The fuel forms are hollow, and once they come off of the binder jetting machine, they’re filled with (TRISO) nuclear fuel particles. These are spherical particles about 1 mm in diameter that have a uranium compound at the center. (This is what fissions and creates heat in a nuclear reaction.) The uranium compound is coated with carbon and silicon carbide, which Terrani says helps provide strong protection against the release of radionuclides. TRISO nuclear fuel has been around for a while, but the particles are traditionally put into a graphitic matrix, which is structurally weaker and doesn’t provide as strong a barrier against radionuclide release as silicon carbide. Once the TRISO nuclear fuel is added to the silicon carbide form, more pure silicon carbide powder is used to fill in the spaces around the fuel particles.

At this point, the 3D printed fuel form is still being held together by binder. Because the temperature resistance makes sintering pure silicon carbide a challenge, chemical vapor infiltration (CVI) is used to create a dense part. When the CVI furnace gets to about 400-500˚C, the binder is vaporized, leaving a porous structure. At 1,000˚C, the part is infiltrated with additional silicon carbide particles, creating a dense, pure silicon carbide part with TRISO nuclear fuel particles enclosed inside. Terrani notes that, because debinding and infiltration take place at the same time, the process is more efficient, and removes the need for operators to handle the fragile parts.

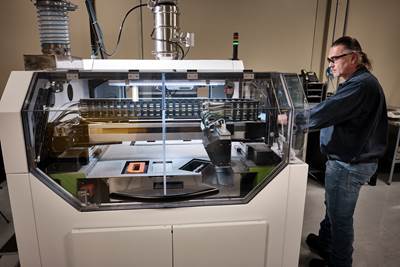

USNC acquired a Desktop Metal X160Pro with a 800 × 500 × 400 mm build envelope that enables the company to print 5,000 silicon carbide fuel structures per day. It’s also printing silicon carbide structural components for the reactors, such as insulators, on the machine. Photo Credit: Desktop Metal

Powering Up

When it comes to geometry, USNC is keeping it simple for now. The fuel form’s current design is a cylindrical pellet that’s 30 mm in height and 21 mm in diameter. Because the nuclear field has very rigorous licensing and regulatory processes, the company is starting with a basic geometry that will be easier to get approved. “So we're not shocking the system, necessarily,” Terrani says. Eventually the company plans to use more complex geometries that include, for example, internal channels. These fuel “pellets” get stacked on top of one another inside the reactor, so they could have different internal cooling channels based on whether they’re at the bottom or the top of the stack. “You can have variable geometry so when the cold gas comes up top, it goes through a different type of cooling channel than towards the end, when it's nicely heated it up and it's about to go out and generate heat,” he explains.

One MMR uses 180,000 of these pellets. That might sound like a lot, but because they’re so small, USNC can print many of them at once. The company recently acquired a Desktop Metal X160Pro with a build envelope of 800 × 500 × 400 mm, which Terrani says can produce 5,000 silicon carbide fuel forms per day. And once the 180,000 fuel forms are printed, the reactor runs for 20 years. This makes the 3D printing process very scalable for USNC. In fact, it also has capacity to use its binder jetting machines to 3D print other pure silicon carbide structural components for the reactors, such as insulators.

These nuclear fuel forms have already been through extensive testing. “We even put these parts inside of the High Flux Isotope Reactor at Oak Ridge, where we exposed them to high energy neutrons, et cetera,” Terrani says. “So we know this material works really well.” USNC is working on codifying its production modules and setting up pilot fuel manufacturing facilities in Oak Ridge and Salt Lake City. The bulk of the company’s 3D printing and CVI will be done in Salt Lake City, while Oak Ridge will do some 3D printing plus uranium processing. And from there, USNC will scale up production.

Terrani says that 3D printing is instrumental to USNC’s technology and business plan. “It's a very tough business. The barriers to entry are rather high,” he says. “Our value proposition is extremely safe reactors, extremely safe fuel. And we're trying to take advantage of the latest advances in materials and manufacturing to have a cost effective solution.”

Related Content

DOE Awards Nearly $3 Million to Develop Additive Manufacturing of Modular Wind Blades

The industry partners received the award to develop automation in additive manufacturing of tooling for large-scale wind blades that can accommodate continuous changes in blade geometry and scale.

Read More3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreIn Power Generation, the Changes From 3D Printing Will Be System-Wide

Additive manufacturing holds promise for various vital components of a gas turbine, and for greater output in hydro and nuclear power as well. Recent articles find many different advances from AM that will sum to transform the power generation sector.

Read MoreAM Will Change Power Generation, But Needs To Prove Itself First

In gas turbines and in nuclear power, Oak Ridge National Laboratory is working with major manufacturers to validate metal 3D printing for conventional parts as a prelude to developing the unconventional ones.

Read MoreRead Next

Cutting Tool Maker Succeeding With 3D Printed Carbide for Oil/Gas and Other Applications

Powders, parts and products are different ways the company is advancing with AM. Carbide and tools are separate areas of success.

Read MoreEstablishing a Process for 3D Printing Carbide

Using its experience making pressed and sintered carbide parts, Hyperion Materials & Technologies developed a new material, printing processes and sintering cycles for 3D printed carbide.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read More