Uniformity Labs Qualifies Stainless Steel Powder for Binder Jetting System

The stainless steel powder is qualified on Desktop Metal’s Production System to deliver double the green strength of existing stainless steel powders over the entire build envelope.

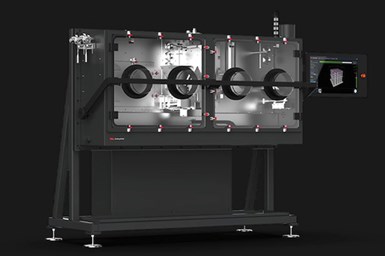

Desktop Metal’s P-1 is designed to bridge the gap between benchtop development and mass production, offering excellent part quality with enhanced process flexibility. Photo Credit: Desktop Metal

Engineered materials company Uniformity Labs has developed an ultra-low porosity 17-4PH stainless steel powder UniJet SS17-4PH performance for use on the Desktop Metal Production System. The material is designed to enable users to achieve serial production with the required repeatability and productivity.

According to Uniformity Labs, during the qualification on Desktop Metal’s Production System, the physical and mechanical properties of UniJet 17-4PH powder were evaluated and the results were outstanding. The highly uniform powder bed layering of UniJet 17-4PH delivers double the green strength and an average of 20% less shrinkage than other stainless steel powders qualified for use with Desktop Metal’s Production System. Along with the high powder bed uniformity, these factors mean better sintered part geometric accuracy and less breakage of green and brown parts during post-print handling and depowdering, resulting in high process yield at high throughput.

One of the key advantages of UniJet 17-4PH is its apparent and tapped densities, resulting in green parts with many more contact points between particles and higher density (10% reduction in relative porosity) than other standard binder jetting powders. This produces green parts with nearly twice the magnitude of transverse rupture strength across all layer thicknesses. Such green parts, alongside the very high flowability of Uniformity powder, make fabricating more complex thin-walled or heavier green parts with larger aspect ratios viable by minimizing breakage during depowdering of large, high-aspect ratio and geometrically complex parts with fine features and channels.

The company says the UniJet 17-4PH powder on the Production System consistently achieved about 25% less shrinkage in X, 19% less shrinkage in Y and almost 20% less shrinkage in Z axes than standard binder jetting powder across all layer thicknesses. The powder repeatably delivers 99-100% final part density for material properties. UniJet 17-4PH powder yielded parts with, on average, three times lower standard deviation in green density than standard binder jetting powder. This roughly translates into three times better absolute geometric tolerance in sintered parts fabricated from UniJet powder using Desktop Metal’s Production System.

The highly flowable powder improves throughput by enabling repeatable fast layering at thicker layers. At a 75-micron layer thickness and with 20% reduced shrinkage (more parts fit on the bed), users can achieve a net throughput benefit of approximately 25% relative to standard binder jetting powders for Desktop Metal’s Production System. That is said to offer a substantial cost reduction which can enable parts manufacturers to begin planning for the adoption of metal AM at scale.

At 110-micron layer thickness — while still delivering all the benefits in green strength, uniformity of powder bed and sintered density relative to standard inert gas-atomized binder jetting powders printing at 65-micron layer thickness — the throughput improvement can be more than 80%.

“The application of Uniformity UniJet 17-4 PH stainless steel for BJT delivers mechanical and process excellence for our customers who require materials that perform to the highest standards across each step of the production process,” says Adam Hopkins, Uniformity Labs founder and CEO. “Our powders deliver superior mechanical properties, printing yield and process stability, delivering repeatable production scale binder jetting.”

The powder enables more users to benefit from Desktop Metal’s high-speed metal 3D printing system for mass production. “This latest addition to our material portfolio allows us to binder jet 17-4 PH stainless steel materials critical to producing complex designs,” says Ric Fulop, Desktop Metal founder and CEO. “Binder jetting powders processed with Uniformity Labs’ technology enables unmatched mechanical properties and can further improve the economics of printing.”

- Read about Uniformity Labs’ collaboration with Desktop Metal for the qualification and delivery of ultralow-porosity binder jetting powders, which are said to enable production of high-precision parts that exhibit excellent material properties and surface finish.

- As part of the ongoing partnership, Desktop Metal and Uniformity Labs developed a fully dense, sinterable 6061 aluminum which is available exclusively to Desktop Metal customers.

Related Content

Desktop Metal X-Series for Metal, Ceramics Additive Manufacturing

The X-Series is said to offer a differentiated approach to binder jetting enabled by Triple ACT — an advanced compaction technology for dispensing, spreading and compacting powders during the binder jet printing process.

Read MoreSafer Nuclear Energy: 3D Printed Silicon Carbide Fuel Forms

Binder jetting provides a way to create pure silicon carbide fuel structures that can withstand the harsh environment of a nuclear reactor and provide a strong barrier against the release of radionuclides.

Read MoreAMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.

Read MoreSintratec Adds More Power in S3 Selective Laser Sintering System

Formnext 2022: The system comes with a 30-W fiber laser, which is three times more powerful than the Sintratec S2, resulting in shorter printing times.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More