Using Hybrid AM, GE Leverages Turbine Blade Repair into Efficiency Improvement

An engineering modification that would have been impractical or cost-prohibitive in the past is realized on a machine tool performing metal 3D printing and machining in the same cycle.

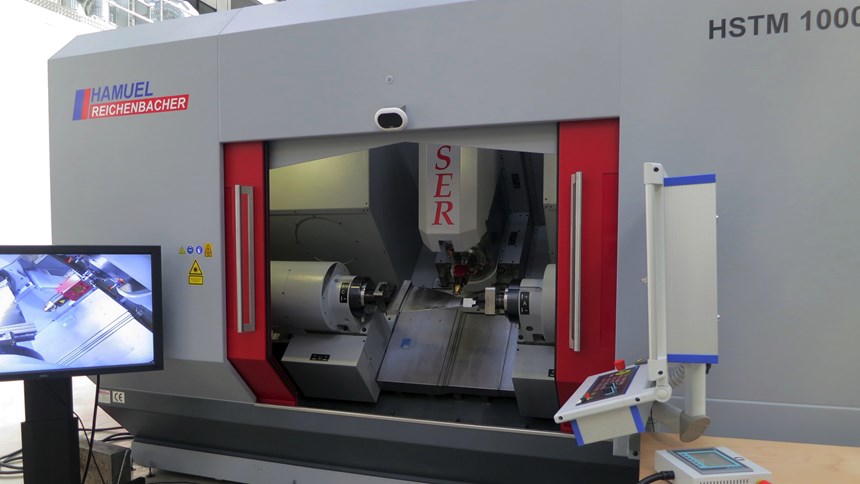

GE is perhaps the major manufacturing company most closely associated with the advance of additive manufacturing (AM). The company’s fuel nozzle for its LEAP jet engine remains a leading AM success story, initiatives such as its Center for Additive Technology Advancement in Pittsburgh promote the adoption of additive throughout the company, and recent acquisitions of companies have made it a supplier of additive technology as well. However, one noteworthy achievement related to AM came because of an additional acquisition. GE is the first production user of Hamuel’s additive and subtractive machining center for turbine blade repair thanks to GE’s acquiring Alstom Power in 2015.

Senior engineer Hartmut Hähnle, formerly of Alstom and now senior engineer with GE Power Services’ Global Repair organization, has been involved with this work on the application of additive manufacturing for turbine blade repair since the proof-of-concept was demonstrated by a UK-funded research project. Now, he describes how the application of metal 3D printing to existing turbine blades has proceeded even farther under GE. At the GE Power Services manufacturing site in Birr, Switzerland, his team recently used the Hamuel machine to not just repair blades, but also modify them for improved performance.

The Hamuel machine realizes additive manufacturing using the “Ambit” system from Texas-based Hybrid Manufacturing Technologies. An Ambit head loads into the machine’s spindle (using the same interface as a toolholder) to allow the machine to perform metal deposition via laser cladding. In its standard version, Hamuel’s HSTM-series machine employs five-axis milling and full turning to enable machining of complex-contoured turbine blade forms in a single handling. The hybrid additive/subtractive version of this machine extend its capability even further, using the direct metal deposition to add surfaces or forms onto the workpiece that can then be machined to precise tolerances within the same cycle. The benefit is “process simplification,” says Hybrid CEO Jason Jones, since those same steps would have been performed in the past on separate machines. However, as the development of the application through Alstom and GE has shown, simplification by itself can open the way into advancing capability.

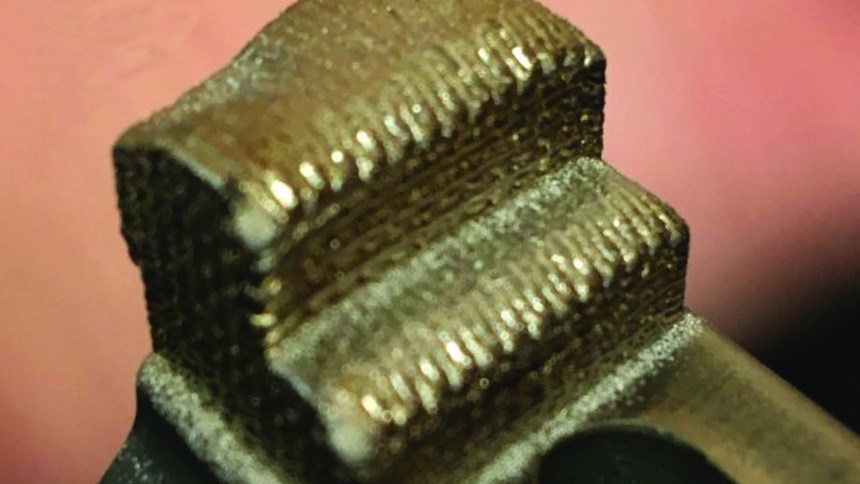

As a straightforward example of a repair, Hähnle cites the blade in Figure 3. The nickel-alloy blade seen here has a “squealer” tip that reduces the gap in the turbine between the blade tips and the ring. Squealer tip restoration is typically done by adding material using one machine and machining it using another. The different machines involve not just different setups but also typically different teams within a plant. By contrast, he says, “A single-clamping situation saves transfer and adjustment time compared to working on multiple machines. In a typical repair with consecutive steps like cutting, cladding and recontouring, [this approach] saves two out of the three transport and clamping steps.” And when it comes to the clamping, he adds, “A secondary benefit is the positioning accuracy of a CNC machine,” which now gets applied not only to machining but also to the material deposition.

Accordingly, he sees the CNC machine tool augmented in this way representing something much more than a conventional machine tool—just like a Swiss army knife is more than a knife and a smartphone is more than a phone. While most blade repair in Birr is still performed through the plant’s conventional approach (because the plant performs a lot of this repair), the hybrid additive/subtractive system is an option now available for the parts that can benefit the most from single-setup processing.

...the option of 3D printing and milling on the hybrid machine drastically changes the economy of a small-quantity modification such as this.

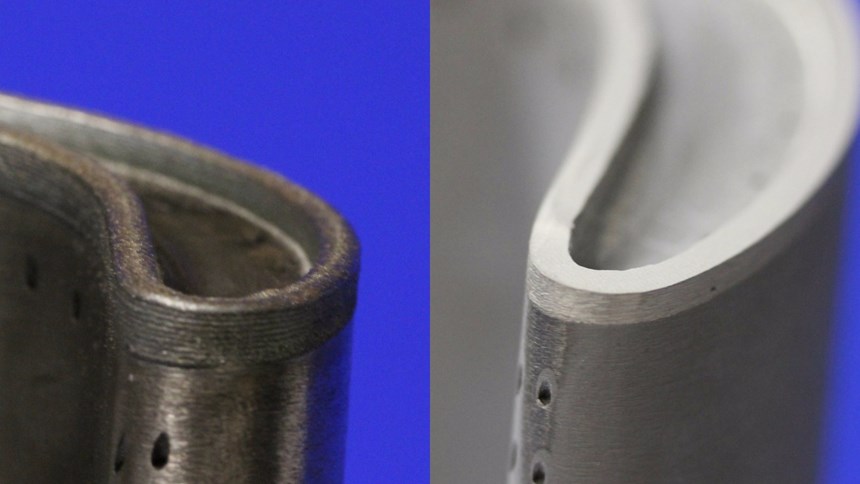

One of the most significant examples of work benefiting from the hybrid processing involved the blade seen in Figures 4 and 5. Measurements of performance in the field (over the course of years) revealed that this blade design could be modified for improved turbine efficiency through the addition of a new feature. The original, conservative design of the blade’s root form and corresponding slot left more space open in the slot than was necessary for cooling. Too much space is a drain on efficiency, since excess air directed to cooling leaves less air available to contribute to power generation through expansion within the turbine. The performance data proved to GE engineers that adding a sealing feature—a feature expanding the root form to fill more of the slot—would improve power efficiency without compromising cooling.

In the past, such a modification likely would not have been made. The cost of new tooling for adding the feature through casting would have overcome any cost savings from improved performance given the small number of blades affected by the discovery. However, the option of 3D printing and milling on the hybrid machine drastically changes the economy of a small-quantity modification such as this. As these blades returned for restoration, they were given the new sealing feature as a simple additional step on the additive/subtractive machine.

Notably, though the batch of these blades might have been small, the job was big enough to encounter a problem typical of production. A crash on the machine resulting from human error damaged the Ambit head. Obtaining a replacement head would take seven days. The machine had no 3D printing capability during this time, meaning blades that were still in need of processing were left to queue and wait.

Jones says the way GE dealt with this problem illustrates the versatility of a system built on the platform of a CNC machine tool. GE turned to another user of an Ambit-equipped machine tool for aid. The blades and the material-addition NC program were sent to this other user for just the 3D printing operation. At Birr, the returning parts with the added feature were then probed for setup location and machined to final tolerance, since the machine at Birr was still fully capable of the subtractive part of the process.

The chance for this kind of redundancy is a strength a hybrid process offers in production, Jones says. Full production at scales greater than GE Power Services’ current work likely would involve multiple hybrid machine tools, allowing work to be routed through these separate machines as easily as the work might be exchanged between similar machine tools in any typical machine shop.

Then again, Hähnle drew a lesson from the crash that offers an even more straightforward option for insuring the hybrid machine’s capability. In production, he says, it’s prudent to be prepared with a spare cladding head.

Related Content

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreCNC Engineering Integrates 3D Printing Solutions With CNC Machine Tools

CNC Engineering and Meltio have collaborated to design a solution that combines the power and reliability of FANUC CNC with cutting edge additive manufacturing technology.

Read MoreRead Next

Highlighting Hybrid Manufacturing

The winner of the first International Additive Manufacturing Award is a company that developed a head for adding metal additive manufacturing to an existing machine tool.

Read MoreVideo: The Additive Nozzle’s Origin Story

The LEAP engine fuel nozzle is likely additive’s greatest success in part production so far, but it wasn’t always clear that the nozzle could be made this way. This video from GE Aviation tells the story.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More