Titanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Share

Read Next

Sporting enthusiasts are always looking for an edge to take their play to the next level. For golfers, that edge may now literally and figuratively come in the form of additive manufacturing (AM).

There are many little tricks and tips to improve a golfer’s game. But one of the best ways to immediately see an improvement is to get better (or the right) equipment. A particular golfer might need a longer putter, bigger driver or even lighter clubs.

Japanese lifestyle golf brand Designer was looking for its own creative edge when it began utilizing laser powder bed fusion, specifically Farsoon’s dual-laser FS200M metal 3D printing system, to create its Titanium Golf Club Line. According to the company, the

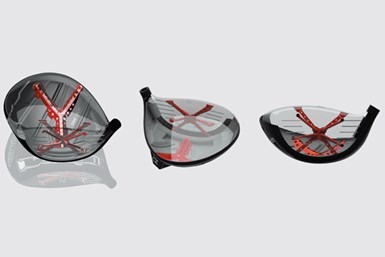

Use of metal 3D printing enables Designer to innovate, design and produce clubheads for players seeking improved performance in distance, accuracy and stability with greater forgiveness. Novel features of the club made possible through 3D printing in a strong, lightweight titanium alloy include a design with self-supported internal structures, and a high-speed impact surface engineered for ductility and strength for the perfect strike. Performing design, development and series production on the dual-laser system is said to result in design-through-manufacturing cost per clubhead savings of about 70% compared to the golf club maker’s conventional processes. A multilayer thickness parameter aids productivity in production.

One-Piece Production, Improved Precision

Assembly consolidation is part of this savings. A typical clubhead geometry includes toe, face, sole, crown, heel and hosel. With Farsoon’s metal 3D printing, the clubhead can be produced in one piece, with improved precision and performance compared to the conventional club. The integrated structure offers greater resistance to twisting, and increased stability and driving distance for the player.

Streamlining Geometries

The company says the 3D printed Designer clubheads include many aerodynamic features to enable wind to flow faster and smoother over the integrated geometry, thereby reducing drag and increasing both head stability and speed. A distinctive “sound window” design is said to offer a more pleasant sound on impact.

Related Content

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read More3D Printed Brake Panel for the Rail Industry: The Cool Parts Show #52

In this episode of The Cool Parts Show, laser powder bed fusion simplifies the manufacturing of air brake panels for light rail systems made by Wabtec.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read More3D Printed Metal Component for CNC Machining Center: The Cool Parts Show #47

Machine tool maker DMG MORI improved this coolant delivery adapter by making the part through additive manufacturing instead of machining. One of the viewer-chosen winners of The Cool Parts Showcase.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More