Shaking Off the Support System

Ultrasonics can remove mold support from the surfaces of an additively manufactured part and reduce cleaning time.

Share

Additive technology has taken manufacturing to a new level but it’s not without its challenges, two of those challenges being supporting parts as they are built and meeting postprocessing requirements. Early on, additive manufacturing was limited in the parts it could produce. “It couldn’t print a part with overhanging shelves, ledges or cavities because there was no way to support them while they printed,” says Frank Pedeflous, president of Omegasonics. That problem was solved with mold support.

Mold support enables 3D printers to achieve the elaborate shapes that in the past could be made only by casting or machining processes. Pedeflous explains, “The mold support works as a reverse image of the finished part—a placeholder, so to speak. This soluble support material is technically classified as a synthetic thermoplastic polymer resin. It is deposited from a second nozzle in the same print head used to print the actual part.”

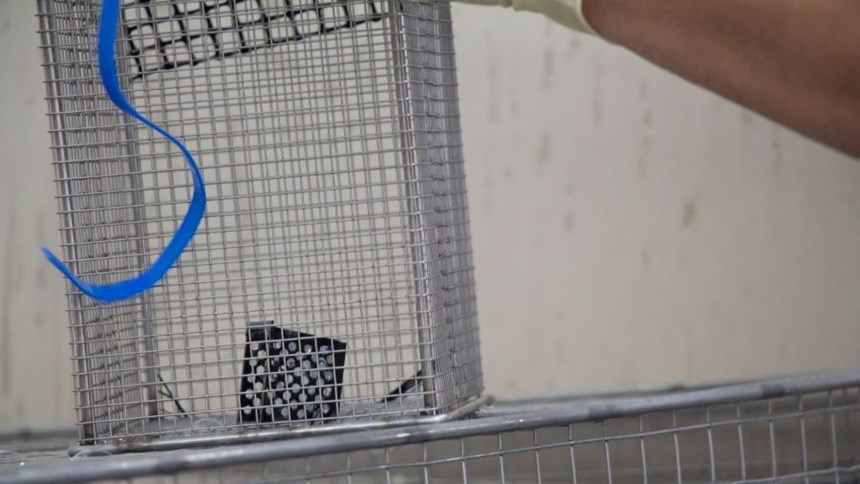

Such support enables intricate, delicate objects to be printed. However, after a part is created and hardened, any mold support or loose material and edges must be removed. This cleaning and finishing stage is where ultrasonic cleaning can help. According to Pedeflous, ultrasonics are a reliable, safe and effective way to remove mold support from the surfaces of an additively manufactured part and to reduce cleaning time compared to manual methods.

Parts could be cleaned with a heated circulating-bath washer or hot-water spraying system, but both of these methods require cleaning cycles that are five to eight times longer than ultrasonic cleaning, Pedeflous says. And high water pressure could potentially damage parts. Also, the larger the object, the larger the requirement for additional process time, cleaning detergent and agitation to dissolve the support material. Manual, hand-cleaning is another option, but this can be very time-consuming, and it may be near impossible to completely remove debris on more complex or intricate structures. Aggressive scrubbing or the use of hand picks can also cause damage to the parts.

“With ultrasonic cleaning, finished parts can be dropped into the ultrasonic cleaning tank, and the support material is gently and completely removed. Parts come out clean of any debris, without requiring manual labor,” Pedeflous says.

He explains that to properly and efficiently clean 3D-printed parts with ultrasonics, parts simply need to be fully submerged into a solution. Since mold support material is water-soluble, a high-alkaline concentrate mixed with water at a temperature ranging from 150°F to 175°F (depending upon the material being cleaned) is the only other requirement.

Parts are not damaged in ultrasonic cleaning, because this process uses cavitation rather than pressurized spray to clean. Cavitation causes vacuum-pressure bubbles in the water to implode when they come in contact with a hard surface, thus removing dirt particles. These small bubbles are able to get into and clean the resin from even the most seemingly inaccessible cracks, crevices, blind holes and passageways.

It might be time to consider ultrasonic cleaning as an integral part of your additive manufacturing process. As described here, it can help remove most mold support quickly and completely, reducing the time needed to manufacture the part and have it ready for the next step in the assembly process, or ready to ship to the customer.

Related Content

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreAM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More