Selective Laser Sintering Cuts Lead Time for Clamping Unit Assembly

Industrial automation provider Comau redesigned a three-part clamping assembly for additive manufacturing, realizing benefits in lead time and waste.

Share

Read Next

As part of its research into additive manufacturing, industrial automation supplier Comau promoted a workshop in July 2015 that brought together experts from the Politecnico di Torino (one of Italy’s oldest technical universities), managers of technology companies and its own technical team. This group’s goal was to explore non-traditional production solutions for large volumes of complex industrial components.

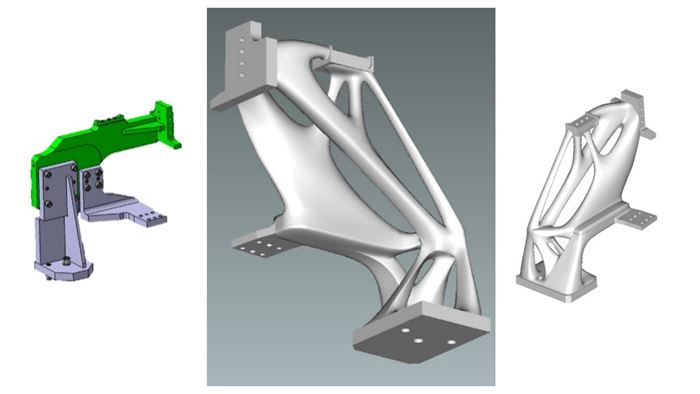

To test the advantages of additive manufacturing, the team chose a sample component to be redesigned: a clamping unit used in Comau equipment to secure pieces for welding and assembly. The company produces thousands of clamping units of different shapes each year, each of them designed based on the type of product that is to be welded. The specific clamping unit chosen for the study is a three-part assembly made from steel S355JR (pictured in Figure 1, left).

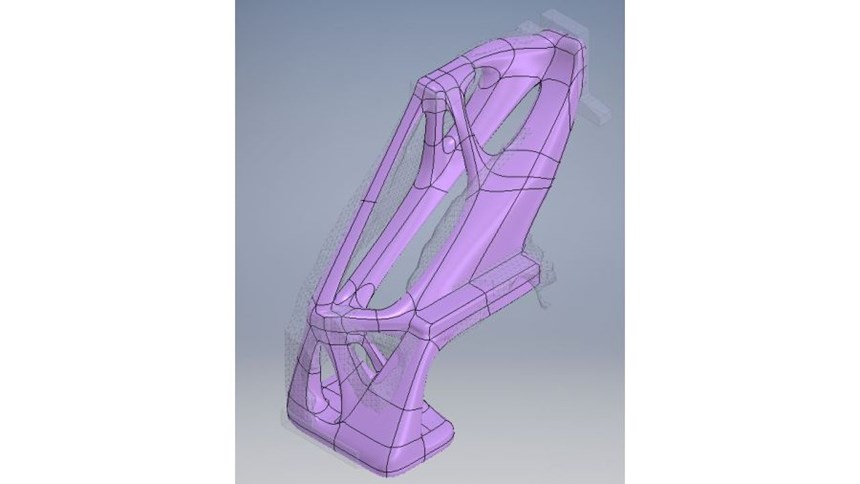

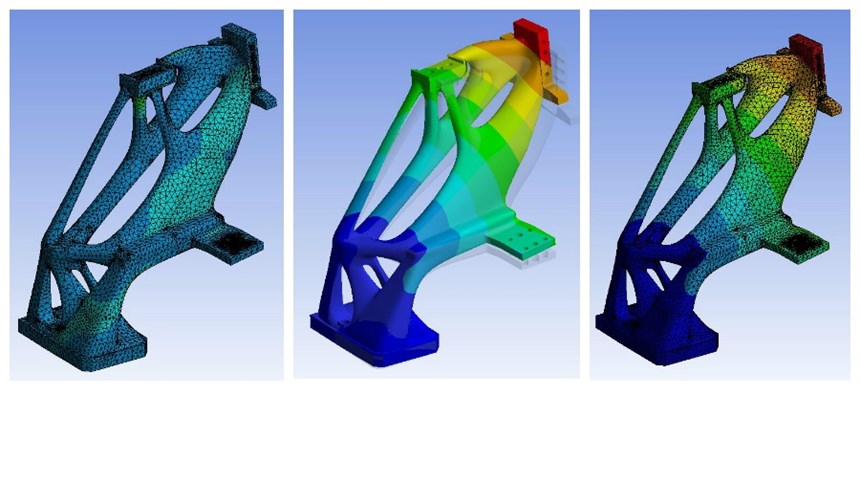

Working from the original component, the team performed topology optimization tests using Inspire software from Altair, Shape Generator from Autodesk and Tosca from Dassault Systèmes. The clamping unit was then redesigned following the shape suggested by the analysis (see Figure 2).

With the new design, the number of components in the unit was reduced from three to just one. The unit’s weight was reduced as the result of optimizing the geometry of pieces in the loading phase. Further weight savings were achieved by changing the material from steel to ALSi10Mg.

The resulting clamping unit was additively manufactured using selective laser sintering (SLS). Postprocessing was performed on the fitting areas and holes, but no assembly was required as the part was printed in a single piece.

The new clamping unit offered some significant advantages over its original counterpart. According to Comau, combining the clamping unit’s original three-part assembly into one 3D-printed component makes it more resistant and durable. The design changes and SLS process resulted in less waste generated during production, and lead time for design and manufacture was reduced by half. The team found that the engineering process was more efficient, and also reduced the logistics required by conventional processes.

In addition to these benefits, Comau says that additively manufacturing the clamping unit allows for more environmentally friendly production systems and “greener” operation. Design changes and the use of aluminum reduced the weight of the part, which could lead to better dynamics for the movable tables on which the clamping units are mounted. This in turn could translate to a decrease in the size of the engines that start the tables, and lower energy consumption. Coupled with the reduced amount of waste created via SLS, Comau sees AM as a possible key element in a “green” factory.

The technical team led by Comau is currently directing the production phase and performing testing to ensure the feasibility of additive manufacturing within industrial contexts. Its objective is to identify other possible applications for additive manufacturing technology, such as complex products or those which require time-consuming and expensive production processes. Comau is also engaged in ongoing internal research to apply AM to industrial production.

Related Content

-

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

-

3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

-

To Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

.jpg;width=70;height=70;mode=crop)