The Additive Manufacturing Conference was held this year at the International Manufacturing Technology Show (IMTS). Hosted by Additive Manufacturing Media, the conference is an annual event for manufacturing leaders focusing on AM for part production. In this segment from the AM Radio podcast, Stephanie Hendrixson, Julia Hider and I discuss our impressions and take-aways. Part of what was notable about the conference this year was the advancing possibilities for directed energy deposition (DED), as evidenced by the number and variety of presentations on this mode of metal AM. Also included were various presentations on AM interacting with established processes, including talks on machining for AM and the new possibilities additive brings to lost-foam casting. In this segment, we also discuss the AM Conference’s evolution next year, when it will become the Formnext Forum in Austin, Texas.

Stephen Feldbauer of Abbott Furnace Company described the development of sintering furnaces tailored to the volume and pacing of production AM.

Transcript

Peter Zelinski

Welcome back. Okay, so first half of the episode you heard the live recording that Stephanie, Julia and I made at IMTS, kind of like our real-time, on-the-spot impressions of the show. Another big part of IMTS for us is the Additive Manufacturing Conference. This is our annual conference. We've been holding it since 2014. We focus on additive manufacturing for production applications and, yeah, every IMTS year we hold it at IMTS. The conference is about to evolve, about to level up next year 2023. I hope we get around to talking about that before this episode is done. But first, like, let's just have a conversation for the people who didn't get to attend our conference. Let's just take a moment and maybe some just some impressions, some takeaways from the Additive Manufacturing Conference this year. Where do you guys want to start?

Stephanie Hendrixson

So yeah, our conference this year, it was a day and a half of presentations, all as you say about like production additive manufacturing. And as I sort of just like looked back through my notes and kind of reflected on the different presentations that we saw, the thing that struck me was that there were a lot of new and emerging solutions for 3D printing with metals. Just to give you a couple of examples, like the keynote that we had on Thursday morning was from HP. We had Ramon Pastor and Meaghan Ferris from HP, the metals division, on stage talking about the new Metal Jet S100 solution, which was probably the biggest additive manufacturing launch at IMTS this year. So we know that HP has been working on this this metal binder jet technology since 2018. That's when they kind of first announced it, actually also on stage at our conference. But they've made a lot of progress in the last four years, they've really built out a full system. So it's not just the printer anymore. There are these little mobile build units that you can pull in and out of the printer. And then they plug into like a powder sieving station and a curing station. And then there's like a powder reclamation station as well. And so they've really tried to optimize it for serial production and scalability.

They also had somebody on stage with them from Schneider Electric, Michael Lotfy. And Schneider is one of the alpha partners that has been working with HP over the last few years to kind of finesse and optimize this product, which is now out on the market. Schneider is using it for these air filters for circuit breakers. But they've got a number of different alpha partners that are doing lots of different things with this technology. Like binder jetting is not new by any means, but this is an example of like a new player entering the market, bringing something different to the additive manufacturing industry.

The other thing that I noticed was like we had a lot of directed energy deposition. We saw presentations from Norsk Titanium, plasma arc DED for really large scale printing, Melanie Lang from FormAlloy talked about powder-based DED. And then like one of the surprising things that came out near the end was we had a presentation from Essentium where they talked about how they're getting into microwire DED. So this is a polymer 3D printing company now getting into metals.

Julia Hider

Yeah, also on the DED front, there was a presentation from Baker and they were talking about wire arc additive manufacturing. So again, big parts and robots, which were a big trend, basically everywhere else at IMTS this year.

Stephanie Hendrixson

Yes. So just like kind of thinking about like that cross section, all these different types of DED, everything from the large-scale robots down to the microwire, and then kind of throw the metal binder jet in there as well. It just sort of struck me that our conference this year didn't have a whole lot of powder bed fusion in it. And that's sort of interesting because I feel like powder bed fusion is one of the most commonly used types of metal 3D printing. But maybe like we've got to a point where it's matured maybe it's not, I don't know, quote unquote, news anymore. And maybe that's why we got like this other mix of metal processes in our program this year.

Peter Zelinski

I kind of hear what you're saying. And I kind of think I hear it, I see it a different way. Like laser powder bed fusion was there, we had a presentation from TAE Technologies. And they're making technology for fusion like they're trying to transform our whole energy supply by developing fusion technology and they work with EOS, they use laser powder bed fusion machines. Like they described how making fusion work means combining magnetic fields, vacuum, particle beams, high voltage to sustained plasma so they're the super complex components. Artem Smirnov is the person from TAE Technologies who presented, one of the parts that he talked about it was called and I am not a fusion expert, but the part was called a neutral beam dump and it, in the original version it had just tons of welds and that took hundreds of hours to produce. Additive, on the EOS equipment, they're using literally a tenth of the time to manufacture the same component. And like I guess what I see in that is like, yeah, the advance of DED was really striking in our conference, but what it kind of speaks to is additive is so young, particularly additive for metal part production, that these technologies are still coming into their own and still arriving. And yeah, I think laser powder bed fusion is probably the farthest along in its arrival. But that just means it's finding these really advanced intricate parts. And yeah, I guess I resonate sort of with the point you hinted at Stephanie, that success and arrival, like the beginning of that is for these technologies to maybe become less visible, because you have, they're serving the applications that they can do really well.

So with laser powder bed fusion, we sort of know the extent of what it can do, and it's considerable. And now we're seeing with the DED, like, we don't know the extent yet. And we're still finding it. Yeah. So with what Essentium showed, so the speaker Elisa Teipel, I introduced her I was the one sort of emceeing at that moment and brought her to stage and I talked about Essentium’s production technology for polymer. I actually didn't realize in that moment where she was going, that she was going to introduce their microwire DED machine. But so clearly, like, the possibility they're exploring is fine resolution, intricate, precise geometries with DED. And I guess we're seeing that in these various other presentations like precision and speed are both advancing the range of what's possible. Norsk Titanium, Carl Johnson, their CTO spoke from Norsk. And so they've been using DED for a while they're established suppliers with various aerospace OEMs and tier manufacturers. But the level they've come to now, he described how they're doing a lot of testing to determine if and when HIPping is needed, and discovering the applications in which they can skip HIPping, which is a huge time and cost savings. And then they're also exploring how little machining they can get away with doing. If they can get closer and closer to net shape, then the chance to reduce machining time is the is one of the best opportunities they see for saving cost for their customers. So all of that kind of thinking and development work is going into the ways DED is being applied to production.

Julia Hider

Yeah, it's interesting that you brought up what, you know, Norsk is looking into with machining and trying to reduce that because Baker actually got its start in additive as a machine shop, they specialized in really big parts. And so they were acquired by Lincoln Electric to help machine some of these really large DED parts that Lincoln Electric was making with their WAAM technology. And that actually leads into another theme I think we saw in the conference, which is AM interacting with conventional processes, including machining.

Peter Zelinski

Totally, right. So established, you know, so called conventional manufacturing processes had a bigger footprint in our additive conference this year than they've ever had. And I think that's a sign of the extent to which additive manufacturing in production is finding its place, becoming established in various applications. And that is very naturally bringing it into conversation with these other part production processes.

Julia Hider

Yeah, so one of the presentations that covered this really well was from Scott Smith of Oak Ridge National Lab, he talked about additive for subtractive. Throughout his presentation, he referred to 3D printed parts as preforms like castings or forgings, and how you need extra stock to account for shrinkage and residual stress and what gets machined away. But there were a lot of other really interesting considerations as well, including designing 3D printed parts with features for fixturing or locating or reducing chatter in machining.

Peter Zelinski

I loved Scott Smith's presentation. It was so interesting because it was so blunt and commonsense. An additive part is a near net shape part generally, it's a very, very, very near net shape part, but it still has to be machined. And actually the nearness of the net shape can be challenging in machining. He talked about the frequency with which parts don't clean up, meaning the quote unquote preform, there's there's a flaw somewhere in the design and it doesn't quite contain the intended final shape. But he also he talked about adding features to additive parts for locating, for fixturing, for stiffening during machining, one of my favorite words is going to be fiducials. He described how attaching 3D printed polymer parts to metal 3D printed parts and these and these added on plastic features are just references for scanning and probing. Scan the whole thing with these reference geometries there. And then it gives you this handy reference to probe off of to find the finished part inside the form. But he also got into really basic stuff, too, that I think is really useful in thinking about how to efficiently apply additive for metal components. He's saying, you know, don't print threads, you're not helping me by printing threads.

Julia Hider

Or his rule for what was it? If you would mill a hole, then you should print it, but if you drill the hole, then you should just drill it.

Peter Zelinski

Yeah, that's right. That's right. That was another great one. He said, “If you print a crooked hole, I'm gonna drill a crooked hole.” Okay, so speaking of commonsense, downstream processes. So, Stephen Feldbauer spoke from Abbott Furnace Company and kind of talked about like sintering furnace considerations for additive parts.

Stephanie Hendrixson

Yeah, this presentation was really interesting, like, this is something that you can sort of take for granted. If you're using metal binder jet, like you need a sintering furnace, you need that step in the process. And a lot of times, we see companies that have adopted this technology, they have like a batch style furnace where you know, you print your batch of parts, you put it in there, and then eight to 12 hours later, maybe you get to take your parts out, maybe longer than that, Stephen kind of made the argument that actually like the batch furnace doesn't make that much sense for additive manufacturing, especially for doing like high mix, low volume. And so Abbott has developed this continuous sintering furnace, specifically for AM. And there's advantages to that, because you can actually change the temperature, you can change the sintering conditions as you're feeding parts into the furnace. So you don't have to stop production, you don't have to totally change over if you need to do a slightly different process for a different material or something like that. And so actually, I thought he made a pretty compelling argument for the continuous furnace, as opposed to the batch,

Peter Zelinski

Right. But it was a continuous furnace tailored to additive. And I guess what that made me think of is, we know this manufacturer RMS, and they're, they're a medical part producer, and Julia wrote this article about how they're an established machining facility, but once they started succeeding in additive, they actually had to establish a new and different machine shop that was tailored to additive and paste for additive. And we'll link to that story in the show description. And they're on my mind, because they were at our conference, we saw them and talked to them at the reception, it was really cool. But here again, with Abbott Furnace, it's a case of additive manufacturing is taking its place in production and is coming into sufficiently widespread use that downstream capabilities, even though they're established capabilities, like furnaces and machine tools, efficient additive manufacturing makes it worthwhile to tailor those capabilities to what additive specifically needs.

Stephanie Hendrixson

Yes, so we saw how additive manufacturing is changing the downstream processes, changing the way that you think about things like machining and sintering. But there are also like other conventional processes that 3D printing is interacting with that we saw examples of. There were quite a few presentations this year that had to do with different types of tooling. So just one example, Sarah Jordan from Skuld, talked about this lost-foam casting process that they do. And so it's similar to like lost-wax casting where you might print or otherwise, you know, make a sacrificial wax pattern and then build a ceramic shell around it. But in their case, they are able to either print the foam directly, or sometimes they print the tool and blow the foam into it. And so the advantage of that is you don't have to burn the the foam out before you cast it. So you sort of save a step there, you can cast directly into that, that foam form. So that was sort of an interesting example, in the casting world. But we saw other types of 3D printed tooling across the conference as well.

Julia Hider

Yeah, you know, on a similar tooling note Nexa3D and PepsiCo gave a presentation about 3D printed tooling for blow molding. Pepsi developed this special system that uses a 3D printed insert made from I think it was PEEK, and they put this into a shell, and they've been able to get 10,000 shots out of these 3D printed mold forms. Whereas their previous experience with 3D printed mold tooling would result in like 200 samples. And the cost is much cheaper, and it's much faster than you know, traditional mold tooling as well. So they've had really good success using this for prototyping and they're working on extending it into bridge production now.

Peter Zelinski

So Thangthip Tekanil of PepsiCo talked about that. The ways they're using these Nexa3D blow mold inserts as part of their as part of their hybrid tooling solution, and the speed with which they're able to innovate new bottle designs because of this approach to blow molding. There was another molding related presentation at the conference. So then actually, as it happened, also involving Nexa3D.

Stephanie Hendrixson

Right, so we saw Nexa3D onstage later in the conference, Izhar Medalsy, along with Carsten Jarfelt from AddiFab and Glen Mason from Wilson Sporting Goods. So Wilson is also using Nexa 3D to make prototype tooling. But they're doing it with this AddiFab process. So it's called freeform injection molding. And basically, the idea is that you can 3D print a tool, shoot your polymer into it, you know, whatever type of molding material you would typically use. And then you can dissolve the tool away. And so this is a great way to do prototype tooling to just test out designs, test out ideas. I think most of what Wilson Sporting Goods is doing right now sort of takes that form. But because the material is dissolvable, it also allows for really complex geometries, things that you wouldn't typically be able to mold because there would be no way to open the mold again, or to get the tooling back out. But because you can just take that part and kind of drop it into a bath and let it sit for a little bit, the innovation here is really sort of like that material that you can, it's strong enough that you can print it and then mold with it, but then it can just be dissolved away.

Peter Zelinski

So different material possibilities, I guess so one more tool example at our conference Fouzi Bahbou of GE Additive gave a presentation on the work that GE Additive is doing in electron beam melting for tool steel. And the example he cited throughout his presentation was it was like a really complex tool form like a gear hub, like a tool like that has a lot of steps if it's made from forging and cutting, but using EBM to get this near net shape form with minimal machining at the end speeds the process. And in addition, it allows because of the high temperature of EBM, it allows for higher carbon content for higher hardness of the tool compared to like laser powder bed fusion. And they're developing not just tool steel made that way, but also tungsten carbide where we're just the binder melts, but not the tungsten carbide particles within the 3D printing build. I guess we've talked a lot about tooling. But before we leave it, Stephanie, you very quickly mentioned Sarah Jordan of Skuld. And she had a line in her presentation that I thought was really striking, a comment she made. You know, she started her presentation by reminding all of us how commonplace castings are in our lives. And she made the assertion that like we're never farther away than like 10 feet from a casting at any time. And so she sort of tested the audience to help them understand that. She's like, if you're wearing a wedding ring stand up, if you're into, sort of gave commonplace examples like of castings that we interact with all the time, that we forget our castings, but her comment was that's eventually the destiny for additive, that eventually, additive becomes invisible, just like casting has become invisible. That's where it's heading. And that's where it's going as it starts to succeed. And, like I thought that was a pretty striking reminder, and it sort of gets us back to like, we're just beginning to see that with laser powder bed fusion. It's less visible at our conference, if it is, only because it's the farthest along in succeeding. And I like think of, thinking about the far trajectory of additive like that, that maybe brings us to like, like one more quick theme we should talk about. And it's just sort of like the broad cultural changes around additive manufacturing.

Stephanie Hendrixson

Yeah, so first of all, I loved Sarah’s presentation. I loved that activity at the beginning and the point that additive is going to become invisible, but I think there's a long way to get there. And so something we heard throughout the conference is how like, additive is this process, but it's also a culture and we're all still trying to figure out like, what is the right culture around additive? How do you really make it successful? Like who are the right players? And how do you think about it? A throwback to the Wilson sport presentation, Glen Mason had this slide where he asked, you know, are you farming? Or are you hunting? There are manufacturing businesses that are farming, where you know, you sort of keep doing the same thing, you cultivate the customers or the work that you already have. But additive manufacturing really lends itself more to the hunting perspective where you're looking for new opportunities, and you're going after them and you're not just trying to do the same thing that you’ve always done. And I think we saw other examples of presenters really kind of pointing out like the different mindset that additive takes and the different parties that need to be involved.

Julia Hider

Yeah, another example of that we saw was Gregory Dudder’s presentation. He's with Hummingbird Additive and his presentation was called “Culture Shock in AM from the Executive Suite to the Manufacturing Floor”. And one thing about his presentation that struck me was that he made the point that if you're using AM properly, it's going to cause a culture shock, you can't avoid it. So you have to figure out how to manage the process successfully. And he had a whole bunch of suggestions for how to do that from building the right team to finding the right business case and not taking on too much at once.

Peter Zelinski

Keselowski Advanced Manufacturing was kind of down that path. They were a presenter too.

Julia Hider

Yeah. So Scott Volk from Keselowski Advanced Manufacturing, he talked about creating an integrated manufacturing strategy, which requires collaboration between additive, subtractive, process engineering, program manufacturing and quality. And one quote he said that I wrote down was, “We don't want to make the most beautiful additive part, we want to make the most beautiful use part.” So AM is just one part of this larger manufacturing strategy.

Peter Zelinski

I wrote down a quote from Scott Volk, too, so yeah, he had this sort of like workflow or discipline flow graph, and he sort of showed how manufacturing usually works and how they expected it to work going in. And it was like from CAD design, to additive to machining to quality, quality to shipping in a straight line. But that didn't work because all of those different stakeholders interact and sort of affect the design and the product and the process. And so now they've got a different arrangement, where it's a circle where all of those stakeholders are at the table together from the beginning. And they figure out from the beginning how to do an additive manufactured part. But he sort of, he was talking about the pitfalls of that linear approach of that one department hands it off to another department approach. And he said that, like he discovered in the case of some jobs, his quote was, “We were so focused on making a perfect additive part, we forgot we have to machine it.”

Stephanie Hendrixson

I guess what it makes me think of is another presentation, Laura Ely, from the Barnes Global Advisors, she was talking about qualification and how like, there are all kinds of stakeholders that need to be involved to qualify additively manufactured parts. But one of the things that she said was metal AM is a team sport. And I think you could maybe just edit that and just say AM is a team sport, you have a lot of people that need to be involved, you have a lot of things that you need to think about. And it works better when there's like a cross functional group looking at these parts and carrying them through the process.

Peter Zelinski

Our friend Tim Simpson sort of gave a talk about the ways that he's struggling with that as an educator. Tim Simpson, professor with Penn State University and a frequent contributor to Additive Manufacturing Media and, and he gave a presentation sort of on workforce development and education for additive manufacturing. He tried to map out the sorts of knowledge areas and skills and attributes that are germane to work in additive manufacturing, and that prospective employers seem to need and it's it's this very diverse array of specific engineering skills combined with soft skills, or even just personal attributes. It's like, it's like a materials engineering knowledge, on the one hand is important, but also, curiosity and imagination are important as well. He pointed out how there's this realm where companies really struggle for what they need in their engineering leaders. And it has to do with making the business case for additive manufacturing, seeing the opportunities, championing the opportunities, pushing into new, lucrative areas for additive manufacturing, making the business case, but universities he very candidly admits, just don't tend to focus there. An engineering university tends more to focus on the engineering considerations of the process. And so even in a fundamental way, the culture of how you prepare engineers is different for additive as well, compared to other manufacturing.

Stephanie Hendrixson

All right, so that sounds like a good stopping place for this conversation about the Additive Manufacturing Conference. Coincidentally, this might actually be our last conversation about the Additive Manufacturing Conference, because it is about to transform into something else. Do you want to talk about that, Pete?

Peter Zelinski

Yeah, we'll go out on that. We had the chance to announce something at our Additive Manufacturing Conference this year, on a previous episode of this podcast, and we'll link to that we talked about our company's partnership, relationship with the creators of the Formnext show, and how we will be launching a Formnext USA trade show. You can go listen to that for details, the fully realized Formnext Trade Show coming to Chicago, that's a big project and it's still a couple years off, but along the way, some other things are gonna change. And one of which is, as part of that partnership, our Additive Manufacturing Conference is going to change. It's going to expand. It'll be a bigger event next year and it'll become the Formnext Forum and that's the name it'll go by from now on starting in 2023. The debut the launch of the Formnext Forum, it will be in August in Austin, Texas, August 28 through 30, specifically, mark your calendars and we hope to see you there.

Stephanie Hendrixson

All right. Join us next year at the Formnext Forum and thank you for listening to this episode. If you liked the AM Radio podcast, please share it with a friend, leave us a five-star review and thanks for listening.

Julia Hider

AM Radio is recorded with help from Austin Grogan and Seth Cooper. The show is edited by Alex Lytle and Stephanie Hendrixson. Our artwork is by Kate Bilberry. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in Cincinnati, Ohio. I'm Julia Hider. Thanks for listening.

Related Content

HB 400 Molybdenum Wire EDM Machine for Metal Additive Manufacturing

IMTS 2022: The HB 400 Molybdenum Wire EDM machine is a 4-axis service system, medium-speed wire cutting machine designed to help users achieve the best surface finish with maximum efficiency and nonelectrolytic power supply technology.

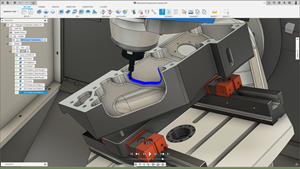

Read MoreAutodesk Fusion 360 Software Enables Generative Additive Manufacturing

IMTS 2022: This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design, engineer and manufacture products to ensure aesthetics, form, fit and function.

Read MoreTop 5 Additive Manufacturing Trends You Can't Miss

Additive manufacturing has made significant strides since the last IMTS. Here are some of the trends to watch for from this year’s conference.

Read MoreFast Wire EDM Machines Remove 3D-Printed Metal Parts From Large Build Plates

IMTS 2022: EDM Network’s mid-sized, four-axis Fast Wire EDM machine is said to provide three to four times faster cutting power.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More