Top 5 Additive Manufacturing Trends You Can't Miss

Additive manufacturing has made significant strides since the last IMTS. Here are some of the trends to watch for from this year’s conference.

It may have been four years since additive manufacturing (AM) suppliers last gathered at IMTS — International Manufacturing Technology Show, but the technology has done anything but stand still in that time frame. Covid forced many AM companies into action, as demand for PPE, medical equipment and testing swabs spiked. Others used the slowdown in 2020 to get back in the lab and finesse their technologies, rather than race to market. Supply chain disruptions in the wake of the pandemic were another spur driving AM forward, as OEMs found 3D printing to be a bridge production or sometimes permanent solution for obtaining the molded, forged or cast parts that had become difficult to obtain.

Now in 2022, IMTS attendees can expect to see evidence of additive manufacturing’s maturity. The last four years have narrowed the gap between AM and many of its more conventional counterparts, and propelled the technology into more markets.

Whether you’re at the conference or keeping tabs from afar, here are five things to watch for from this year’s IMTS:

1. Parts for Electric Vehicles

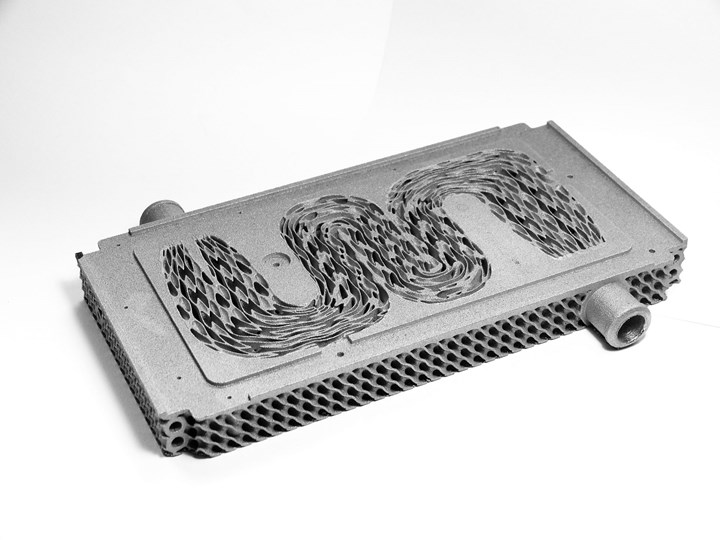

EVs represent brand-new product lines for startups and established automakers alike, and this brings an opportunity. Without incumbent supply chains, tooling and processes, additive manufacturing can step in with a clean slate and bring all of its benefits in terms of geometric possibilities, lightweighting and consolidation. Look for 3D printed heat exchangers, pistons, brackets, aesthetic details and other components intended for these next-generation vehicles to get a sense of additive’s capabilities when given free rein.

Heat exchangers are a critical part of EV engines that help keep electronics within their operating temperature range. This 3D printed aluminum cold plate (part of the The Cool Parts Show display in Booth 236600) for an electric race car was a collaboration between students at the University of Milan, nTopology), Puntozero and M4P. Photo Credit: nTopology

2. A Focus on Mold Tooling

Injection mold tooling remains an important application for 3D printing, but new options have recently entered the market. You’ll find laser powder bed fusion printers exhibiting complex tools with conformal cooling of course, but also keep an eye out for processes based on easier-to-handle metal paste as well as printers that can use more durable plastics and polymer-based composites to deliver mold tooling suitable for prototype, bridge and short production runs. Mold tooling is becoming faster and cheaper to obtain with these solutions (and many can be applied to end-use parts as well).

3D printing brings new geometric possibilities like conformal cooling to injection molds, as well as potential benefits in terms of lead time and workflow. This medical device tool made by Mantle was 3D printed using metal paste and required no surface finishing before being used for production injection molding. Photo Credit: Mantle

3. Higher Productivity Polymer 3D Printers

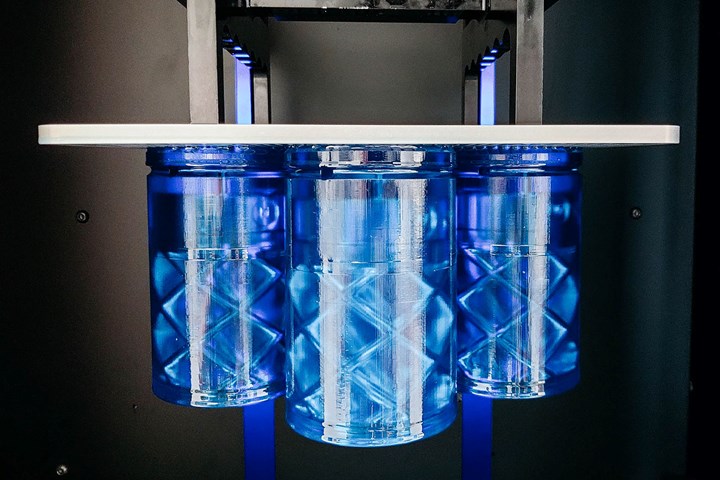

Cost and speed have historically held polymer AM back from capturing production work. Several of the exhibitors at this year’s show are displaying digital light processing (DLP)-style machines and other polymer systems designed to optimize 3D printing, bring costs down, speed print cycles, and make this technology more competitive with injection molding. In most cases these machines are also highly effective for rapid prototyping, meaning that a new design can be printed, tested and validated before moving into production on the exact same platform.

Digital light processing (DLP) uses UV light to cure liquid resin into layers that build up parts. Nexa3D is one of several suppliers showcasing printers designed for scale that use this process. (Coincidentally, the parts shown here are also examples of Trend 2: They are mold tools created through the company’s partnership with AddiFab.)

Photo Credit: AddiFab

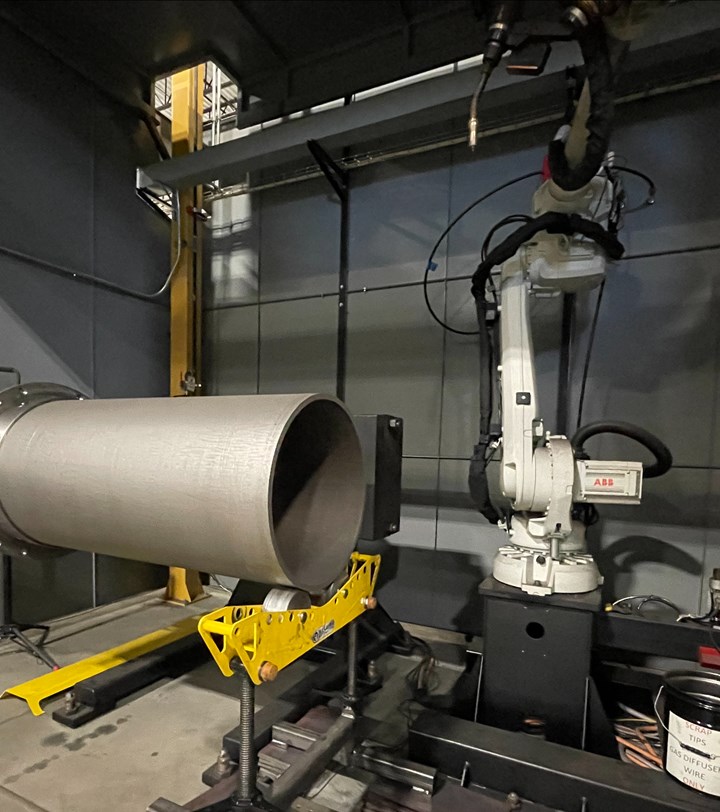

4. More Part Suppliers on the Show Floor

The cost of getting started with additive manufacturing can be prohibitive, despite potential benefits. At this year’s IMTS, a significant number of exhibitors are highlighting not equipment, but services. Using these services rather than immediately bringing equipment in-house is an opportunity for manufacturers to test ideas and assumptions before going all-in on 3D printing. A good partner can not only help with design for additive manufacturing (DFAM), including process and material selection, but can also aid in developing and qualifying a production process, even for regulated industries such as aerospace and medical.

Lincoln Electric Additive Solutions is one of a growing number of additive manufacturing technology developers that do not sell a printer, but a service. Customers can contract the company to produce large metal components (often used as near-net alternatives to castings) through its wire arc additive manufacturing (WAAM) process.

5. More Options in Metal 3D Printing

Producing metal parts through 3D printing no longer requires a dedicated and very expensive machine, along with a host of postprocessing equipment. Keep an eye out for printheads that can be integrated into existing machine tools or with robots; smaller, more affordable metal printers; and systems that have been designed to minimize postprocessing, shortening the time from design to finished metal part. Another trend in metals worth mentioning? Multimaterial 3D printing. Look for show pieces that combine multiple alloys in a single print, like copper incorporated into steel for thermal transfer or Inconel added to surfaces for wear resistance.

Look for new metal 3D printing options that are lower cost, more flexible and offer new material options. Meltio’s stand-alone machine and add-on print head both use metal wire, which allows for interesting combinations of alloys. The cubes in the foreground are sample parts each pairing two materials, while the drill head in the background combines three: stainless steel 316L for the body, ERCuSi-A for cooling channels inside and Inconel for the top portion.

Related Content

How Additive Manufacturing Is Transforming EVs and Transportation: AM Radio #23

As 3D printing is adopted into the electric vehicle (EV) market, it is not just vehicles that are being reshaped. In this episode of the AM Radio podcast, we discuss additive manufacturing and the future of transportation.

Read MoreAn Additive Solution for Copper Inductors and Heat Exchangers

Solution delivering more capable inductors debuts as standard product for other fine-detail copper needs.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreVelo3D Qualifies Aluminum Alloy to Support Formula 1 Customers

Aluminum alloy supports Formula 1 customers by enabling the production of parts requiring high thermal conductivity and durability, and is available to print in both 50 and 100 micron layers.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)