Recently I had the opportunity to visit Protolabs’ new direct metal laser sintering (DMLS) facility in Raleigh, North Carolina, where the company continues to expand its additive offerings. The contract manufacturer has seen the increasing demand for additive over the course of a decade now.

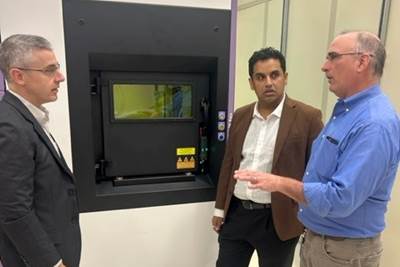

I spoke with the company’s president and CEO, Robert Bodor and 3D printing applications engineer manager, Eric Utley to learn more about this long-term demand growth and the new facility, which was built from the ground up.

Protolabs’ new direct metal laser sintering (DMLS) facility opened its doors the first week of October 2023. Built from the ground up, this facility will accommodate the growing demand for metal additive.

The new site sits directly across from its predecessor, a facility that used to house all of the 3D printing technology at the Raleigh campus but now houses only the non-metal 3D printing capacity. The new DMLS facility is metal-focused, and Protolabs is in the process of moving these machines to their new 120,000-square-foot-home.

A Growing Portfolio

Protolabs began its manufacturing journey in 1999 with injection molding for plastic prototype parts. The company saw an opportunity in its development of automated software solutions to assist with short-run manufacturing by speeding order processing and workflow. It expanded beyond injection molding, opening facilities worldwide to offer additional services such as quick-turn CNC machining, and industrial-grade 3D printing. Its most notable new investment relates to the changing role of this last capability.

“Protolabs is continually excited by additive manufacturing and the opportunities found in this space. More and more we see AM’s potential for production parts,” Bodor says.

A Tale of Two Facilities

The new facility offers the Protolabs team necessary freedom in terms of facility design, workflow and functionality for increasing volume of metal AM work. Touring both facilities made clear how the newer one was built to respond to challenges seen in its predecessor.

As the original facility housed all available AM technologies, it was filled to the brim after about six years in existence. “This speaks a lot to the evolving nature of additive. New technologies, machines and support equipment are continually being discovered in this space,” Utley says.

The new facility plans to gradually expand its metal additive manufacturing options to ensure long-term demand is successful. Purposefully empty space holds possibilities for new technologies to come.

That filling of the original facility space happened even though the capacity expansion was methodical. Every technology selection was evaluated to assure it met a variety of customers’ needs and would be long-lasting in terms of life span and relevance.

The expectation of similar growth, therefore, served as a motivator in the creation of the new facility. “Right now, the DMLS facility is purposefully starting out at about one-third of the way full,” Utley says.

DMLS Facility Opportunities

Out of the 120,000 square feet, 60,000 square feet (part of it unfilled) has been reserved for DMLS printers. Currently, there are 33 DMLS printers and counting with space to fit a further 91. Over 75 employees are dedicated to DMLS operations. The current DMLS machines are all from GE Additive. They include two X Line 2000R large format printers, 17 M2 machines, 12 smaller Mlab machines and two Mlab 200R machines.

The image above depicts a pair of Mlabs DMLS 3D printers. Protolabs continues to move its metal printers from the old facility into the new. Photo credit: Protolabs

“We are able to generate about 80,000 to 100,000 printed parts monthly for a variety of customers,” Bodor says.

Throughout the new facility, electronic boards depict the progress of active projects. The open floor plan has clear divider curtains separating spaces. In the DMLS area, parts from different customers can be seen being printed at the same time, often on the same build plate (if they share compatible geometries) to save time and cost for each job.

This area of the new DMLS facility is where human-hand detailing is applied to parts that customers wish to further finish and customize.

The new facility also offers a variety of equally important support equipment to supplement the additive machines with postprocessing. Capability areas include an on-site CNC machine shop and an expansive materials and quality laboratory space (still being filled), with plans for a dimensional metrology unit.

Additionally, the facility offers postprocessing options such as bead blasting, painting, dying and human-hand detailing for customers wishing to further finish their parts.

Related Content

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreA Tour of The Stratasys Direct Manufacturing Facility

The company's Belton manufacturing site in Texas is growing to support its various 3D printing applications for mass production in industries such as automotive and aerospace.

Read More6 Considerations When Launching an Additive Startup

Recent additive manufacturing (AM) startup owner, JP Kinerk, shares his experience by offering helpful advice for others just starting out in the additive realm.

Read More