Optimized LPBF Reduces Cost Per Part by 90 Percent

Through a combination of laser powder-bed fusion, design and optimization technology, Betatype reduced the cost of an automotive part from more than $40 to less than $4.

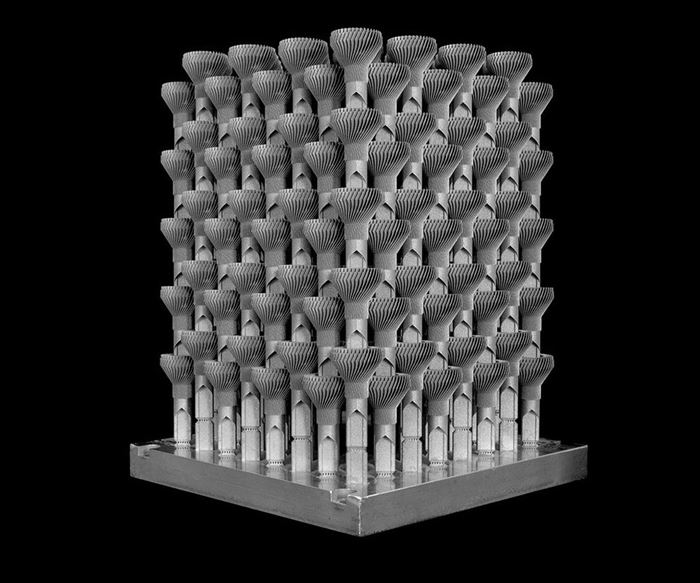

High volumes, productivity and cost-per-part are often cited as shortcomings of additive manufacturing (AM) for production applications in industries such as automotive. But AM process optimization that boosts productivity can reduce cost and support greater volumes. Betatype, a developer of AM optimization technology, recently worked on an automotive project using laser powder-bed fusion (LPBF) to produce 384 qualified metal parts in a single build, leveraging design and optimization strategies to reduce the cost-per-part.

Founded in 2012, Betatype has developed “Engine,” a data processing platform for managing and controlling multi-scale design. The technology can be applied to design complex parts that could not be easily built through traditional processes. Data processing also makes it possible to manage and optimize every tool path within each part, the company says, by shortening laser scan paths and delays. Geometry-driven control allows for the selection and application of laser parameters on an exposure to exposure level, enabling greater quality control and more efficient melting.

With the right part design, tool paths and parameters, additive manufacturing can be a more cost-effective method of production, as illustrated in Betatype’s manufacture of heatsinks for LED headlights. Typically, these components require comparatively large heatsinks which are often actively cooled. Betatype recognized that the specific geometry for these metal parts made them ideal for producing with LPBF.

By considering the LPBF process at the initial design stage of the component, Betatype was able to design a part with built-in support features, which allowed multiple headlight parts to be stacked on top of each other without the need for additional supports. Full stacking is often difficult with LPBF due to the thermal stresses involved in the layer process; by intelligently designing the structure to reduce thermal stresses, Betatype was able to make it a viable option with minimal thermal distortion. It was then possible to snap apart the finished parts by hand, without the need for further postprocessing.

For the collective 384 parts, Betatype was able to reduce build time from 444 hours to under 30 hours. Reducing the build time for these parts also reduced cost-per-part, from upwards of $40 to under $4.

The design of the part and supports enabled a series of parts to be “nested’” together to maximize the build volume, resulting in 384 parts being produced in one go within a single build envelope by Progressive Technology on an EOS 280M system.

Through specific control parameters, the exposure of the part in each layer was reduced to a single tool path, with minimal delays in between. This toolpath strategy, coupled with Betatype’s optimization algorithms and process IP, reduced the build time of each part from 1 hour to under 5 minutes per part, the company says.

For the collective 384 parts, Betatype was able to reduce build time from 444 hours to under 30 hours. Reducing the build time for these parts also reduced cost-per-part, from upwards of $40 to under $4.

The EOS M280 is a single-laser, medium-frame (SLMF) system; with a multi-laser, medium-frame 3D printer, Betatype’s optimization approach could reduce build time to less than 19 hours. Using one of these high-productivity systems would enable 19 times the productivity over a year of production per system, increasing volume from 7,955 parts to 135,168, Betatype says. With an installation of seven machines running this optimized process, volumes could approach 1 million parts per year, and those parts could be more functional and more cost-effective than those made conventionally.

Related Content

Autonomous Cobot Automation Increases Production 3D Printer Output for Ford (Includes Video)

A mobile robot that travels to each Carbon machine to unload builds lets the automaker run an additional three to four builds per machine per day. Autonomous robots fit well with 3D printing, but their role in production will extend beyond just the additive machines.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More