How GM Is Investing in Additive and EVs

People within the automaker aren’t just working with additive, they are actively promoting it to their colleagues throughout the organization.

General Motors is investing $81-million to produce an all new Cadillac, the CELESTIQ, an electric vehicle (EV).

The monies are being invested in the purchase and installation of equipment for the flagship sedan, which is expected to go into production in late 2023.

The Cadillac CELISTIQ will be hand built. And more than 100 of its parts will be made with additive.

The Cadillac CELISTIQ will be hand built. And more than 100 of its parts will be made with additive.There are a few things to know about this:

- The vehicle is “flagship” in terms of price, as vehicle cost estimates range from $300,000 to above $400,000.

- Production of the vehicle is not going to be performed at an assembly plant, but at the GM Global Technical Center in Warren, Michigan, a campus where design and engineering, not manufacturing, are the primary activities.

- The CELESTIQ, says GM president Mark Reuss, will be “hand-built.”

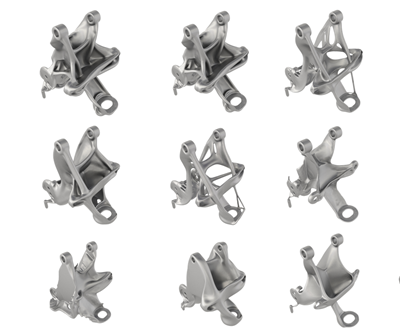

- And the most relevant to this space: The sedan will have more additive parts — cosmetic and structural, metal and plastic — than any other GM vehicle, and not by a few. It is estimated to be in excess of 100 parts.

As you can imagine, we went to GM additive personnel and asked for some details on what they have planned.

And as you can also imagine, we were told that they were not planning to release any additional details about the future product.

So we talked with Ali Shabbir, additive design and manufacturing product application engineer, who works at the GM Tech Center (and whom we talked with about the use of additive for the Cadillac CT4-V and CT5-V Blackwing models* last year) to see how additive is advancing at the automaker.

Then & Now

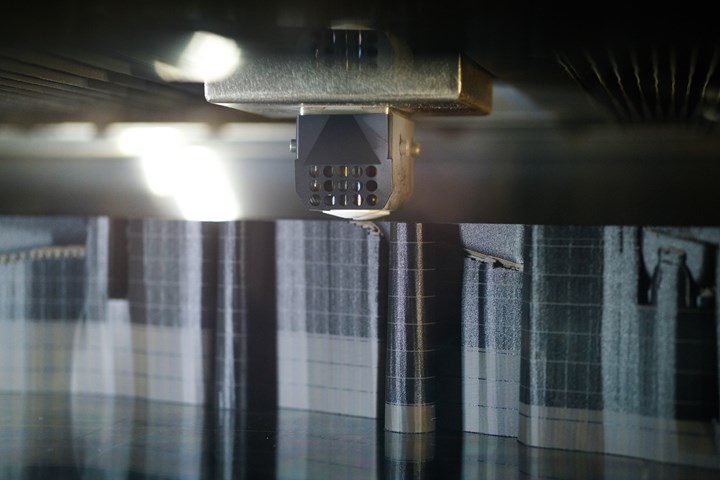

In December 2020 GM opened a 15,000-ft2 Additive Industrialization Center (AIC) at its tech center. It included 24 machines — SLS, SLM, FDM and Multi Jet Fusion.

Today, Shabbir says, the approximate number of machines remains the same, but “It is a dynamic space.” He explains that machines are moving in and out of the space as team members familiarize themselves with the equipment and the materials.

“We want to determine the true capabilities of these machines, then find homes for them in other facilities.”

While GM has long been working with additive processes, it is undertaking a concerted effort to train more designers, engineers and manufacturing people in the why, how and where of the technology, people who are likely more familiar with machining, molding and stamping. Photo Credit: GM

The components for the Blackwings notwithstanding, Shabbir says that there is no serial part production occurring at the AIC right now. He says that team members are working to develop “profound knowledge” of the technology, and are pushing the equipment to its limits.

This will allow them to understand what characteristics are needed in order to move toward serial production operations.

Functional prototyping, however, are something that they are performing in earnest at the AIC. “This is in the spirit of getting products to the market faster,” he says, explaining that the AIC is able to produce the parts that are used in testing in much less time than it would take to tool parts for more traditional build methods.

Shabbir says the applications are varied across vehicles, with engineers who are familiar with different sections of a vehicle all examining the opportunities for additive. “We see applications everywhere.”

One of the things that he and his colleagues are doing is evangelizing for additive. He says that there is a grass-roots initiative among members of his team to go out and work with other designers, engineers and manufacturing people. They are establishing standards and specs to facilitate deployment.

He acknowledges that there is a bias in the organization for using traditional machining and molding techniques, but that they are working to make the opportunities and advantage obvious to people.

One way this is occurring is through the Additive Innovation Lab, a setup in GM’s Cole Engineering Center with approximately 14 commercial-grade machines. Shabbir describes it as something of a “maker space.” He notes that pre-COVID there was plenty of foot traffic around the lab, which drew a lot of interest. Odds are that as more people go back to the Tech Center this interest will continue.

What They’re Looking For

There are two primary categories: materials and machines.

As for the first, Shabbir says GM would like to see the material portfolio expanded, especially “more of the steels and aluminums automotive might use—at a cost that makes sense.”

He says that polymers are a heavy usage material, but he says that finding the right ones for the application can be challenging.

In light of the supply chain issues that have affected production for the past couple of years, Shabbir says the company is not interested in single sources for materials.

He says it would like AM materials to go to something of an open-source model.

On the subject of equipment, he says, simply, “bigger is always better.” He points out that whether looking at a vehicle’s interior or exterior, there are large panels and parts. The alternative now is to cut the design of a part in CAD, print the pieces, then join them after the fact.

For machines that are used for polymer applications, he says he’d like to see a work envelope of a meter in each direction; for metals, 600 mm.

The GM Global Technical Center campus is on 710 acres in southeast Michigan. There are 22,716 employees at the site. The corporation is investing $81 million there for equipment to manufacture the Cadillac CELISTIQ, which goes to the point of how this hand-built car will be something of a technological tour de force for GM, as while there is manufacturing engineering performed at the Tech Center, there is no manufacturing per se. Photo Credit: GM

One More Thing

Shabbir says that it isn’t all about printing parts, that economics have to be taken into account. When looking at a given part, he says it needs to be asked: “Does additive improve it or is it good as it is?” Even parts that could undergo topology optimization might be better off as they are, given that the modified structure could result in additional post-processing that means additional costs.

“You have to have knowledge of the entire value stream,” Shabbir says.

*The two Blackwing models are low-volume vehicles, meaning that there are only a few hundred of each produced. To put this into perspective, they are based on the standard CT4 and CT5 models, and in all of 2021 those two cars combined had U.S. sales of 16,699 units—all variants. Of all GM vehicles, the Corvette is undoubtedly the most niche—but even in its case in 2021 there were 33,041 sold, approximately twice as many as the CT4 and CT5 combined. That’s low volume.

Advancing Electric Vehicles Through Additive

Next-generation vehicles are coming that will be made possible only through the advantages that AM provides. 3D printing enables lightweighting, materials, optimized designs and more that will drive EVs even farther in the future. READ MORE

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreHow Additive Manufacturing Is Transforming EVs and Transportation: AM Radio #23

As 3D printing is adopted into the electric vehicle (EV) market, it is not just vehicles that are being reshaped. In this episode of the AM Radio podcast, we discuss additive manufacturing and the future of transportation.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreRead Next

Why GM’s Electric Future Is Also an Additive Future

Production capacity isn’t the only reason that additive has been slow to make inroads into the automotive industry. There is a larger barrier to entry—one that General Motors and Autodesk are working to overcome.

Read MoreCadillac Blackwing Models Are First GM Cars Using Additive Manufacturing for Full-Scale Production

Three functional components are 3D printed thanks to cost savings and design freedom. Layers lines on the shift knob signify this advance.

Read More3D Printed Tool for Machining Electric Vehicle Motors: The Cool Parts Show #39

Additive manufacturing achieves a large-diameter cutting tool light enough for fast, precise machining of the motor housing’s stator bore.

Read More

.jpg;width=70;height=70;mode=crop)