Sand 3D printing is changing the way that Humtown Products delivers cores and molds to its foundry customers. But the technology could have implications beyond castings.

“Traditionally we were a tooling shop, making patterns and molds and core boxes,” says Brandon Lamoncha, director of additive manufacturing (AM) for Humtown Products. “Then we added a CNC machine shop. Once additive manufacturing came out, it seemed like the next linear step — the next logical progression of technology.”

In some ways Humtown’s progression from manual to CNC and now digital, additive manufacturing of sand cores and molds mirrors the evolution that has taken place in the surrounding Youngstown area — from Steel Belt to Rust Belt, and now a reawakening as part of America’s “Tech Belt.” Not many manufacturers have survived through all three phases, but Humtown Products is one exception. The company has supplied sand cores and molds to foundries across the United States and around the world since its establishment in 1959.

Today the company operates five sand 3D printers at its Leetonia, Ohio, facility, possibly the largest concentration of these machines in the United States. This sand 3D printing capability has allowed Humtown to respond to customer demand for faster delivery and easier design iteration, but is much more than a product development tool. The company now 3D prints cores and cavities for reverse-engineered and legacy parts; bridge and short-run production; and production-scale cores and molds. But this technology is even taking the company outside of foundry tooling all together, into new applications for sand made possible by 3D printing.

Getting into the 3D Printing Sand Box

Brandon Lamoncha today leads the Leetonia-based Humtown Additive, just a short drive away from the company’s main facility in nearby Columbiana, Ohio. His father, Mark, is president and CEO of Humtown Products. Father and son began exploring the possibility of adding sand 3D printing to the company’s services about seven years ago, but the economics didn’t immediately make sense. A conventionally made foundry sand tool generally costs 2 to 4 cents per cubic inch, whereas 3D printed sand cost 17 cents or more per cubic inch at that time.

Brandon Lamoncha (left) and his father Mark at Humtown Additive in Leetonia, Ohio. The former Mitsubishi facility is home to five large-format sand 3D printers from ExOne, with room to expand.

But the Lamonchas were committed to vetting the technology, and eventually partnered with the University of Northern Iowa (UNI) to assess the usefulness of sand 3D printing. Brandon Lamoncha went to Iowa to collaborate with the professor running the school’s sand 3D printer, picking up tribal knowledge about the sand binder jetting process while bringing real-world applications and customers to generate revenue for the program. The expertise gained at UNI later helped Lamoncha establish sand 3D printing within Humtown’s main business, when a partnership with Youngstown State University and a MAMLS grant (Maturation of Advanced Manufacturing for Low-Cost Sustainment, a program from America Makes) made it possible to bring the company’s first ExOne S-Max in-house.

Each ExOne S-Max has two job boxes on a track (visible on either side of this machine), allowing the previous build to be removed from the 3D printer for unpacking while the next build progresses.

The strategy worked so well that in 2019, the sand 3D printing operation outgrew its original facility in Leetonia and moved to a larger building. Formerly a Mitsubishi factory, the new Leetonia facility already had the 12-foot concrete foundation needed to support the large sand 3D printers, as well as plenty of electricity drops and heavy-duty overhead cranes which allowed Humtown Additive to get up and running quickly.

Today there are five sand 3D printers in total: four ExOne S-Max printers each with two build boxes, and a larger machine owned by a customer (not pictured in this article). Future updates will include HVAC systems on the production floor and additional printers, but the facility as it stands has been made operational in less than a year.

“We think of the two facilities as tooling and tooling-less,” says Mark Lamoncha.

Unlike most other 3D printing processes, the postprocessing of sand cores and cavities is fairly simple so there isn’t much auxiliary equipment on site aside from vacuums and downdraft tables like this for removing loose sand. Once cleaned, the sand molds are packed on pallets and padded with furniture foam to protect them during shipping.

Use Cases for 3D Printed Sand Tooling

The price for 3D printed sand has come down in recent years, to a range of about 7 to 10 cents per cubic inch today. Conventional cores are still cheaper, but 3D printed tooling has proven to be a win for applications where it can save time, as in product design iteration, or offer design advantages. 3D printing’s ability to print complex geometries makes it possible to combine cores and cavities into fewer pieces. This saves on labor but also consistently leads to a better cast product, Mark Lamoncha says.

“If you have multiple pieces of tooling that are glued together, those glued joints are an opportunity for the casting to fail,” he explains. Printing those pieces together avoids assembly but also eliminates joints for reliability and consistency in the casting step. Related benefits can come from this consolidation as well, such as the ability to eliminate draft angles in the 3D printed tooling and potentially save weight in the final part. Typically, the best uses for 3D printed sand are tools for smallish, complex parts that would require many assembled components.

Brandon Lamoncha holds the 3D printed sand core that replaced the blown sand core for the engine block water jacket.

In one instance, the company was working on the tooling for an engine block water jacket. The core for the part was being made conventionally, by blowing sand into a cavity. But there were quality problems in the sand blowing process, leading to a spongy sand core that failed repeatedly in the casting process and resulted in a high scrap rate for the cast part. Humtown discovered it could build a stronger, more uniform core using sand 3D printing — while still producing the rest of the tooling conventionally. This blended solution also means “blended cost” says Mark Lamoncha, which makes it more attractive to customers than fully 3D printed tooling.

There have also been cases where it makes sense to pursue both conventional and 3D printed tooling at the same time. 3D printed sand molds can generally be obtained weeks or months faster than conventional, which enables it to be used for initial runs, bridge production and stop-gap manufacturing.

“You can dual-path your product and develop it for both at the same time,” Mark explains, citing one example where a customer utilized sand printed cores to produce parts while waiting for the conventional tooling to be made and delivered 16 weeks later. The company has also provided supplemental production in the form of quickly printed sand molds when conventional tooling was temporarily unavailable.

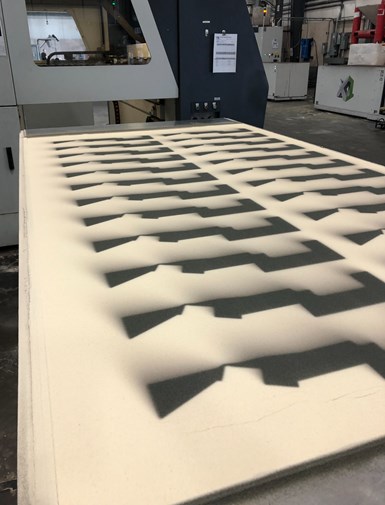

Each build in an S-Max printer can produce dozens of sand cores or molds at once, making sand 3D printing a viable tooling production technique for the right part.

The main goal and focus at Humtown Additive, though, is full-scale production tooling. It has produced sand cores and molds in quantities of a few hundred a month, up to a gamma run of automotive parts that required 8,000 tools in total. While these quantities have been manageable with the existing 3D printer fleet, the Leetonia facility offers ample room for expansion and the digital nature of additive manufacturing will make it easy to bring on new capacity when needed.

“If sand 3D printed tooling makes sense at 8,000 pieces, then it will make sense at a greater level,” says Brandon Lamoncha. “All we’d need to do is put in more printers, and we could make 150,000 or 200,000 pieces. All it takes is more machines.”

Cost-Effective Foundry Tooling from the New Tech Belt

Admittedly, there is slightly more to it than floorspace and advanced manufacturing equipment. Capturing that production work in the first place will mean winning orders for sand cores and molds that might have been made conventionally, and quite possibly overseas. It’s a matter of cost as much as anything, but Humtown has at least one trick up its sleeve here: people.

Like most other companies, Humtown Products suffered in the 2008 recession. But how the company dealt with its setbacks, including staffing reductions, was unique. Mark Lamoncha implemented a visual earnings model still in use today, where wages are connected to pieces produced per hour through a software algorithm. At the same time, shift lengths were reduced from 8 to 6 hours, with employees free to choose the 6-hour shift that works best for their lives. The approach, he says, makes employees into elite “industrial athletes,” incentivizing them to become experts in their jobs and operate at their best while at work. “When you can engage and empower people to self-management, they feel like they’re performing, just like they would in any sport,” he says.

The changes worked, not only keeping the company afloat but allowing it to thrive. Per-hour wages more than doubled and productivity increased by more than 350%, while employee turnover and scrap rates dropped. Today just 30 employees keep the two facilities running 24 hours a day, and 6 or 7 days a week. The system recently earned Humtown an award from the National Association of Manufacturers (NAM) for talent management leadership, and the patented software will be scaled for public use at some point in the near future.

With sand 3D printing, the process of building the form of the core or mold is completely automated; employees can focus on tasks like design and build unpacking that still need a human touch. Photo Credit: Humtown Additive

Aside from the benefits to employee morale, work-life balance and more, Humtown’s unusual workforce management strategy also dovetails well with the more recent addition of additive manufacturing. The automated nature of AM means that the sand 3D printers can produce more tools with less human involvement; the process is largely unattended, with operator labor primarily focused on the delicate work of post-print unpacking and cleaning of builds. If Humtown can continue to innovate and grow this technology alongside an “industrial athlete” workforce, Mark Lamoncha believes the company will be well-positioned to compete with overseas suppliers and keep work in the U.S.

“We’re hoping that additive manufacturing can be better priced here than anywhere in the world,” he says.

Beyond Foundry Applications

While foundry sand cores and molds remain the core of the Humtown Additive business, the company is also exploring other applications for 3D printed sand. Some we’ve covered in the past, with Humtown providing sand molds for vacuum- and thermoforming to Catalysis Additive Tooling in Powell, Ohio. By infiltrating the sand with resin and applying proprietary coatings, Catalysis has been able to make these forms durable and smooth enough for repeated use in these forming processes.

But the same principle can be applied to applications beyond tooling, allowing 3D printed sand to actually serve as the end-use product itself. The material is cheap, only a little more expensive than standard foundry sand, and can be built up with precision into any geometry. With the addition of a resin to hold the material together, 3D printed sand can approach the durability of plastic 3D printing or injection molding for end-use parts.

When I visited in August 2020 (my first such outing since March, as a result of the coronavirus pandemic), I actually saw durable sand prints in action. Like many other 3D printing companies, Humtown has been involved in producing personal protective equipment (PPE) for local organizations as well as its own use. As we toured the shop floor, many employees were wearing face shields consisting of a clear plastic piece over the mouth and nose, attached to standard safety glasses with a bracket — which I later learned was resin-infiltrated 3D printed sand.

These brackets for face shields are among the end-use applications for 3D printed sand that Humtown is exploring. In its green state (left), the printed sand is too delicate to be used as PPE and can be easily broken. But after resin infiltration (right), the brackets are suitable for use, with durability approaching that of plastic injection molding.

Humtown has also applied this solution on a larger scale to art installations and architecture restorations, working primarily with Freshmade 3D, a Youngstown-based service provider with an outpost in the same Leetonia building. The latter has developed the specialized resins that can be used to strengthen these sand 3D printed parts, as well as AMClad, a composite material that can be applied to create a smooth finish while preserving detail. Together Humtown and Freshmade3D have worked on a number of high-profile projects such as a replica statue currently on display at Ellis Island.

“[W]e want to commercialize this as far as we can take it.”

But aesthetic pieces likely aren’t the only use case for this combination of technologies. As the face shield brackets suggest, Humtown is also actively exploring other uses for resin-infiltrated sand in cases where it could be a cost-effective alternative to injection molding, metal 3D printing or other processes.

“We don’t even know all the applications for 3D printed sand yet,” Brandon Lamoncha says.

“We’ve adopted 3D printing with an eye toward innovation,” adds Mark Lamoncha, “and we want to commercialize this as far as we can take it.”

Related Content

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreRead Next

Casting Goes Digital with Sand 3D Printing, Nondestructive Testing

Tooling & Equipment International (TEI) used to make tooling for castings. Now, it casts prototype parts in a digital workflow using 3D printed sand molds in combination with simulation software, CT scanning and X-ray technology.

Read MoreLook Again: This 3D Printed Part Isn't Plastic

This radiator cover is comparable in strength to an injection molded part, and was made at lower cost than 3D printed polymer.

Read More3D Printer Parts Made with 3D Printed Tooling: ExOne Walks the Walk

Accelerated timelines, fast design changes and low volumes — in many ways, 3D printing is the right market for 3D printing. ExOne’s newest generation of machines includes parts vacuum formed on 3D printed tools developed by Catalysis Additive Tooling.

Read More

.jpg;width=70;height=70;mode=crop)