Additive Manufacturing’s Manifold Benefits

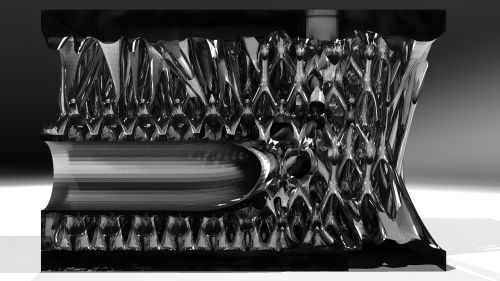

How would you make a weight-bearing manifold without machining?

Within Technologies provided the photograph of this part, which was produced additively using a machine from EOS. Within also provided the rendering showing a cutaway of the part’s design. Within makes software tools that simplify the creation of complex geometric structures according to the engineering requirements of a component. Another example of a part designed in Within and produced on a machine from EOS (in this case, at IMTS) can be seen here.

Related Content

-

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

-

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

.jpg;width=70;height=70;mode=crop)