5 Lessons About Additive Manufacturing We Can Learn from This Part

A bracket redesign has a lot to say about the successful application of metal AM. One of the takeaways: Support structures are worth the effort!

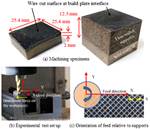

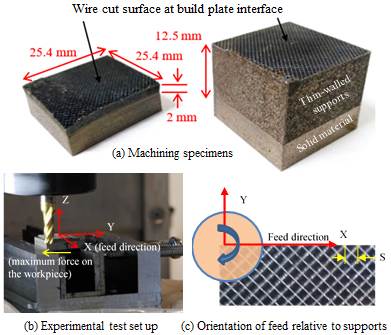

Four parts were 3D printed on the build plate. According to Corey Dickman, the grid pattern helped ensure a more even distribution of powder throughout the initial layers, aiding in realizing a secure bond to the plate.

The part pictured above has a lot to say about metal additive manufacturing.

I saw this part during a recent visit to the Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) at Penn State University. Penn State R&D engineer Corey Dickman, who was involved in the project, provided background information.

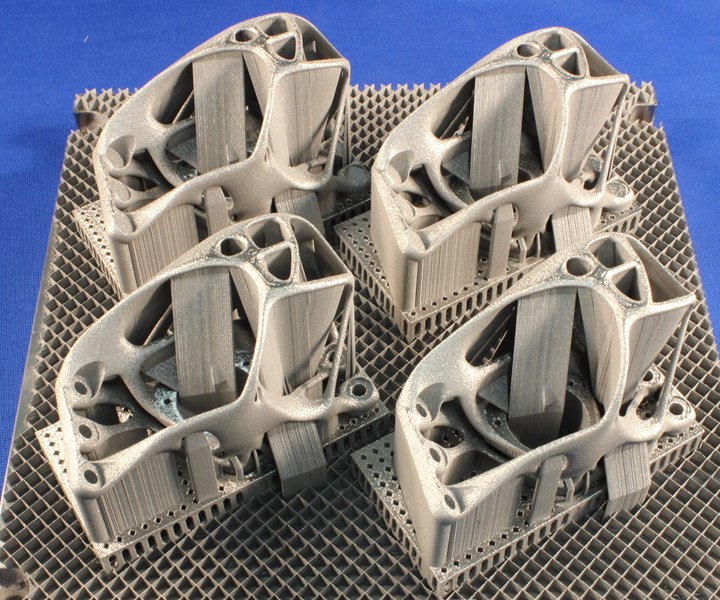

The part is a bracket. It was 3D printed for the U.S. Army Aviation and Missile Research Development and Engineering Center (AMRDEC) to replace a more conventionally shaped bracket made through more conventional means. The new, titanium bracket was redesigned for additive manufacturing (AM) by Materials Sciences Corporation, which employed topology optimization to realize this form. CIMP-3D produced it via powder-bed fusion.

The part illustrates some fundamental points about additive manufacturing. Namely, additive provides a means of making complex parts; additive and topology optimization go together; and additive offers a means to work with harder-to-machine materials such as titanium. But get past these basics, and this part has even more to say. The part also illustrates more subtle points that have proven to be important to the successful application of metal AM, including all of the following:

1. Brackets are an important additive manufacturing opportunity

We must no longer be bored by brackets. Brackets are frequently regarded as afterthoughts, and generally designed to simply follow the lines of the members they join. But brackets hold together structures all around us, largely determining the strength, resilience and integrity of those structures. In the past, engineers haven’t had the means to optimize the geometric forms of brackets for their precise intended performance, and they haven’t had the means to manufacture those forms even if they could. Now they have both: generative design or topology optimization, complemented by additive manufacturing. In various industries and applications, better brackets will enable us to improve how well assemblies, housings and vessels are put together.

2. Topology optimization will extend forms into strange spaces

This particular bracket serves well to illustrate how strange an optimized form might be. Materials Science Corporation used its own internally developed topology optimization software to mathematically search out the form of this bracket best able to simultaneously meet the Army’s two goals of low mass and high stiffness. The result is a bracket that (returning to the point above) truly is not boring. The assumption is that brackets generally ought to obey the same spatial boundaries as the forms they connect, which the original version of this bracket did. By contrast, topology optimization revealed that the best-performing form for this bracket extends some of its mass into space the previous bracket did not touch. As additive manufacturing becomes more commonplace, we should expect more and more manufactured objects—brackets and beyond—to feature this kind of strangeness.

The additive bracket with a 3D-printed replica of the original bracket it replaced. Compared to the conventional bracket, the topology-optimized version projects some of its minimal mass into previously unused space.

3. Support structures can be a significant portion of the additive build

Support structures can be significant not only in terms of the amount of material used (material which then becomes scrap) but also in terms of the amount of engineering time spent designing these supports. According to Dickman, the design challenges of the optimized titanium bracket included angling the supports to avoid intersection with other parts of the build geometry and to make them accessible for later removal, as well as dividing the supports into separate groupings, also to aid in removal. But the time spent on developing effective supports was all worth it, in part because of the next point.

Support structures are a significant part of the build—significant in both material use and engineering attention. However, the value extends beyond the build itself, because these supports also serve as the part’s workholding for machining.

4. Support structures anticipate secondary processing

A metal additive part is generally a machined part, and this is particularly true of a bracket, a part that (by its nature) has to mate precisely within an assembly. Properly designed support structures anticipate the machining step, positioning and securing the part to speed this work. That was the case with the support structures for this job, which served as the part’s workholding during machining. Indeed, these supports provided the most effective workholding imaginable, protecting the otherwise fragile part against chatter.

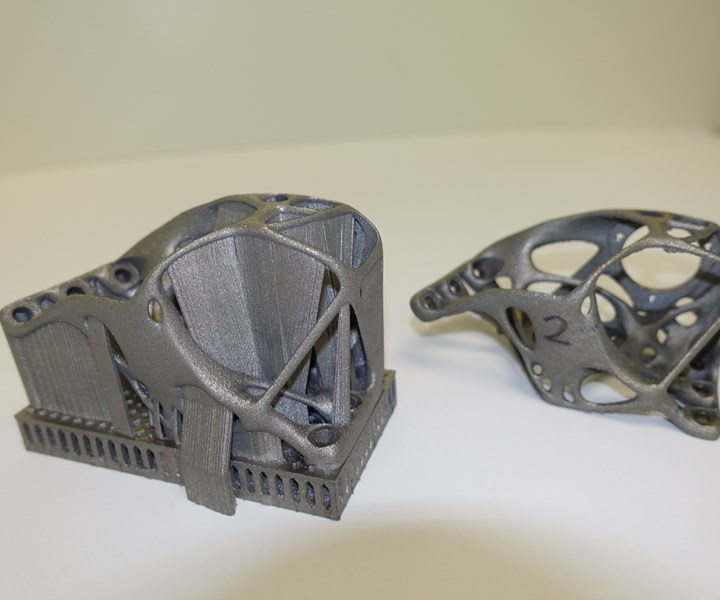

5. With additive, complexity does not inhibit reproducibility

This final point is additive’s secret weapon, and it is the point that will hasten AM’s adoption into higher-quantity production as the efficiency of additive processes continue to improve. For a complex part made conventionally—perhaps through many painstaking steps or setups—the process that led to one part being made successfully does not necessarily translate to scale production of that same part. This is not the case with additive. With additive, the considerations are still numerous, relating to factors including material, machine parameters and support structure. But once the additive process has been proven, it is a straightforward matter to repeat as many parts within the same process as the machine’s build capacity will allow. For the bracket, for example, producing four parts on the build plate was as easy as producing one.

Some say “complexity is free” with additive, and this is not precisely true. Greater complexity can lead to more demanding support structure considerations, and those considerations are not free. However, there is a statement almost as powerful that can be made without qualification. Namely, with additive, complexity is easily scalable.

Related Content

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreMultimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.

Read MoreRead Next

Topology Optimization Delivers Nonintuitive Design Features for Legacy Part (Includes Video)

Refurbishing a legacy turbine engine for energy efficiency provided the opportunity to demonstrate topology optimization in concert with metal 3D printing. The design for this torque arm comes from computer simulation insight refined with a human touch.

Read MoreHow Would You Make This Bracket Better?

When design constraints are taken away, what does the very best design for a given application look like?

Read MoreHow Machinable Are Support Structures in a Metal 3D-Printed Part?

What happens when you cut away thin-walled supports on your metal 3D-printed part?

Read More