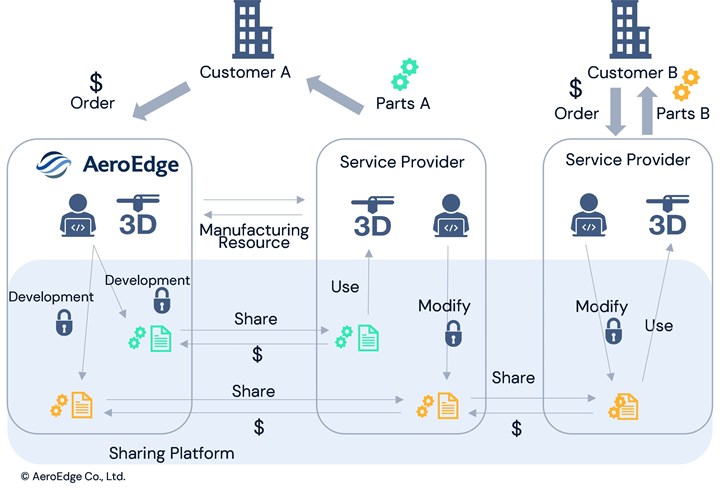

A distributed manufacturing network poses many challenges: Quality assurance, version control and IP protection for traveling files, among other considerations, all have to be addressed for such a network to be realized. But perhaps the more fundamental challenge is finding and developing the manufacturing capacity to actually carry out the distributed production. One company working on many of the former problems has recently announced a collaboration to help address the latter.

3DOS, a platform designed to enable decentralized manufacturing, is partnering with AeroEdge to offer metal additive manufacturing in Japan. The latter company will 3D print metal components in-house on its hybrid directed energy deposition (DED) and electron beam melting (EBM) equipment, and serve as a hub to dispatch polymer 3D printing work to other local partners.

Founded in 2016, AeroEdge is primarily an aerospace manufacturer and supplies critical components including titanium aluminum turbine blades for the LEAP engine through a direct contract with Safran Aircraft Engines of France. The company’s capabilities include CNC machining equipment and advanced inspection technologies as well as AM machines including the GE Additive A2X EBM platform and the Lasertech65 DED hybrid from DMG MORI.

3DOS builds on the success of 3DPrinterOS, a software-as-a-service (SaaS) cloud solution used for 3D printer management by some large organizations, including NASA, Google and John Deere, as well as more than 100 universities around the world. The software allows users to send 3D print jobs to networked printers and remotely monitor their progress. 3DOS users can order 3D printed parts in a similar fashion, with the work automatically dispatched to an appropriate manufacturing node.

AeroEdge will be a key partner in the 3DOS decentralized manufacturing ecosystem, both as a hub for distributing 3D printing work and as a provider of 3D printed parts. Image Credit: 3DOS

As a partner within the 3DOS decentralized manufacturing network, AeroEdge will now serve as one of these nodes and help to introduce the platform to the Japanese manufacturing market. As with any other 3DOS-enabled manufacturing site, customers ordering printed parts will be able to protect confidential information through digital technologies and monitor the print in real time.

“AeroEdge is the first major industrial metal AM partnership on the 3DOS platform, and we are working together to pilot and test the system,” says John Dogru, 3DOS founder and chief architect. “We are extremely excited about the partnership, signed MOU and shared vision to decentralize AM manufacturing globally.”

The two companies connected through Berkeley SkyDeck, a startup accelerator and incubator at the University of California. According to Dogru, AeroEdge and 3DOS share “the same vision for decentralized manufacturing.” AeroEdge will initially serve industries including transportation, military and the aerospace industry, including digitizing the LEAP engine blades already manufactured by the company.

“We will also push 3DPrinterOS/3DOS into the university space in Japan to train the next generation on on-demand manufacturing,” Dogru says.

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreUnderstanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)