Decentralized Manufacturing Network Aims to Make 3D Printers a Shared Global Resource

The 3DOS additive manufacturing network will let OEMs and creators take advantage of open 3D printer capacity anywhere in the world.

Today the manufacturing industry is buying and using 3D printing incorrectly — so says John Dogru, founder and CEO of 3DOS and 3DPrinterOS. With a background in electrical engineering, computer science and building just-in-time automated manufacturing systems at Dell, Dogru points to the cross-compatibility of computing equipment as a north star toward which the 3D printing industry should steer. The typical PC user searching Google isn’t conscious that the search engine is accessing multiple global servers to deliver information locally. The same server-client model found in the computer industry can apply for 3D printing as well.

That’s the idea behind 3DOS, Dogru’s company that aims to create a global decentralized manufacturing network in which anyone can upload a design, receive royalties and have their products produced anywhere in the world. Similar to the way that Google provides information seamlessly around the globe, the ultimate vision is to deliver on-demand 3D printer access worldwide.

Software is a critical piece of executing this vision, and 3DOS takes advantage of an earlier innovation. Dogru’s other company, 3DPrinterOS, was founded 10 years ago to improve connectivity across 3D printing equipment. The software makes it possible to access and control multiple networked 3D printers, no matter the make of the machine or where the user happens to be.

At Duke University, for instance, a farm of more than 150 printers is running on 3DPrinterOS. More than 7,000 students are able to access this resource in real time, on demand through the cloud-based software; they can upload a part file, deploy it to an open printer, and within a few minutes watch the print begin through a webcam inside that specific machine. Similar systems are in place at other universities, as well as within OEMs and other enterprises. (The list even includes Google, where engineers use the software to access the company’s 3D printers across 40 locations.) Some 60,000-plus 3D printers are already using the software worldwide.

Individuals including engineers, designers and celebrities will be able to take product designs to market instantly.

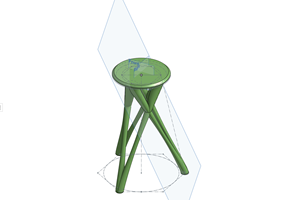

3DOS takes networked 3D printers even further. Built on the back of the 3DPrinterOS software, the 3DOS additive manufacturing network enables users to have parts produced on equipment they do not own. While the platform is launching with just a few partners at first, the vision is that individuals such as engineers, designers or celebrities will be able to take product designs to market instantly, with low or no risk. Items can be listed for sale through any e-tailer, with no need to produce inventory in advance. The designer receives a royalty when a purchase is made, and then — and only then — is the item produced, automatically at a network member close to the purchaser using the printer and material(s) designated by its creator.

That automation is key to providing seamless global production. Customers purchasing products are essentially sending orders directly to the machines, without any human intervention. That means service bureaus that join 3DOS don’t need added overhead to manage the orders, while also taking advantage of work that comes without marketing or sales effort. Sending production close to the customer also has benefits in sustainability and supply chain logistics.

“We locate the nearest printer, just like DoorDash, and the customer can choose to pick it up locally or have it shipped locally,” Dogru says. “This eliminates at a minimum transcontinental shipping, taxes, tolls and carbon footprints.”

Benefits of Distributed Production

3DOS represents the opportunity to bring manufacturing closer to end users, who benefit from the reduced shipping and lower costs of localized manufacturing. For design contributors like OEMs, it also provides the opportunity to supply spare parts from a “digital catalog” or help fill supply chain gaps with agility. Participating in the 3D printing network could even be a way to scale production without adding more of their own equipment.

Perhaps more significantly, however, the network is a convenient way to launch a potential new product into the market for OEMs as well as creators outside of manufacturing — which is why the company’s current beta phase is focusing on high-profile design partners. Early collaborators on this front include Toyota (for replacement parts), the Drone Racing League (for on-demand production of drone components) and Ozzy Osborne (for collectibles — a not-insignificant part of the opportunity 3DOS could present).

“If it doesn't sell, they don't have to burn millions of dollars and a year of building product, only to find out no one wants it.”

“For all of these brands and influencers, currently there is a high barrier to entry, [as well as] cost and risk, to try to take a product to market,” Dogru says. “We make it easy for them to test merchandising. If it doesn't sell, they don't have to burn millions of dollars and a year of building product, only to find out no one wants it.”

For manufacturing partners, joining the 3DOS network is a way of monetizing idle printers and potentially helping to finance new equipment. Manufacturers don’t need to be dedicated to the network, but can take on work when there is excess capacity after meeting their own needs. Many existing 3DPrinterOS customers are preparing to onboard into the network as both suppliers and customers.

Building on Blockchain

Of course, sending part files potentially around the world introduces issues around security and intellectual property. For this, 3DOS is turning to elements of blockchain, the same technology behind cryptocurrency and NFTs. In the case of 3D printable items, 3DOS uses blockchain to protect royalties, validate authenticity and rarity of the part, and verify its current owner. Payments and other information could be tracked through blockchain ledgers in the future.

3DOS is currently in beta, launching with just a few additive manufacturing partner facilities and a handful of high-visibility clients. The company has just completed a pre-seed round, and for a limited time is accepting public shareholders through StartEngine.com. Funding will go toward generating revenue with the initial group of clients, with the aim of ramping up toward higher-margin deals. Long term, the goal is to make the network a de facto way of moving a product from the digital to physical worlds, with as little friction as possible.

“The future of 3D printing is to make the ecosystem interoperable and reduce cost to go to market,” Dogru says, and 3DOS’s software-first approach to distributed manufacturing could address both aims at once. "3D printers are best used as a shared resource.”

Related Content

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreSolving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreTo Scale Additive Manufacturing, Separate Design and Production

Spokbee’s online marketplace is designed to ease the launch and sale of customizable, 3D printed products. Its flexibility comes from cloud-based CAD and a distributed network of service bureaus for production.

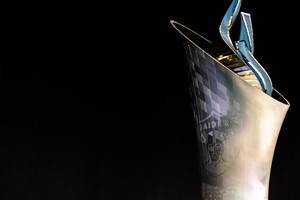

Read MoreThe World’s Tallest Freestanding 3D Printed Structure

Dimensional Innovations paired additive and subtractive manufacturing to create a monument for the NFL’s Las Vegas Raiders new stadium. The “never been done before” project resulted in the world’s tallest freestanding 3D printed structure.

Read MoreRead Next

How Tilt Hydrometer Fights Supply Chain Disruption with 3D Printing

The maker of a digital hydrometer for beer brewing keeps its supply chain and product flexible through selective laser sintering of a critical component.

Read MoreThe Manufacturing Network as a Source for Internal Custom Tooling

For a tool that includes both machined and 3D-printed components, all the pieces of the tool can be made by separate companies yet arrive together. BMW has used Xometry to obtain tooling in this way.

Read MoreBlockchain-Protected Designs As the Enabler to Distributed 3D Printing

IP protection and control over batch sizes are challenges to localized manufacturing through 3D printing. An EU collaboration is working on a blockchain-based solution.

Read More

.jpg;width=70;height=70;mode=crop)