LPBF

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

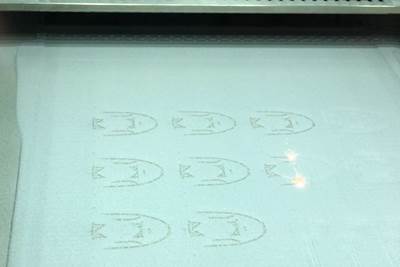

WatchHow to Rapidly Calibrate 4-Laser Production LPBF Machines

Multi-laser machines introduce an additional source of variation; the separate lasers have to synch with one another. At this Indiana additive manufacturer, one-third of the laser powder bed fusion machines are multi-laser. Here is is the AM calibration tool this company uses.

Read More3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

Read MoreMaterialise and Renishaw Integrate Systems to Improve Efficiency of Metal 3D Printing

Renishaw system users can now benefit from Materialise’s build processor software as well as its Magics data and build preparation software.

Read MoreVideo: Ergonomics and Economics of Really Big Laser Powder Bed Fusion

The DMP Factory 500 solution currently operating at CIMP-3D offers a look at the equipment and steps necessary to 3D print metal parts at large scale.

WatchHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreSouthern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

ListenEOS M 290 1kW Metal AM System Engineered for Materials, Applications That Demand Higher Intensity

The EOS M 290 1kW metal printer features a one-kilowatt laser with the flexible, midsize frame to deliver the power needed to maximize production of industrial applications for copper and copper alloy, with more materials coming.

Read MoreAdditive Plus to Distribute Farsoon Technology on West Coast

With an open system providing full laser control, Farsoon’s technology offers the freedom to work with any material and control all printing parameters.

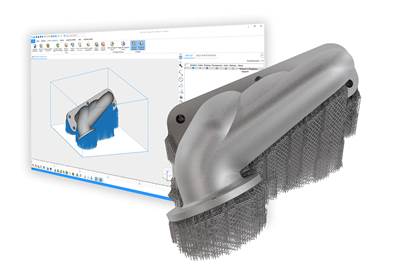

Read MoreMaterialise Software Module Optimizes Data and Build Preparation for Metal LPBF

The e-Stage for Metal+ software uses physics-based modeling to improve automated support structure generation for laser powder bed fusion.

Read More

.png;maxWidth=300;quality=90)