Liqcreate Creates Flame Retardant Polymer for High Temperature Applications

Parts made with this additive manufacturing resin can withstand high temperatures without posing a fire hazard due to its self-extinguishing capabilities.

Share

Read Next

Dutch independent 3D printing material manufacturer Liqcreate has developed an engineering 3D printing resin called Liqcreate Flame Retardant HDT, which features high temperature resistance in combination with a UL94 V0 flammability rating. This rating is essential for a wide range of engineering, mobility, consumer goods and electronics applications.

The resin is an extremely rigid off-white photopolymer that can be processed on most resin-based 3D printers. The resin is compatible with digital light processing (DLP), liquid crystal display (LCD) and laser-based 3D printing systems operating in the range 385-420 nm. The 3D printing parameters for multiple printers can be found on the Liqcreate website.

Parts made with this resin can withstand high temperatures without posing a fire hazard due to its self-extinguishing capabilities. With an HDT-B value of 257°C / 495°F, it is well suite for high-temperature applications. Also, with its UL94 V0 rating, it is suitable for applications like interior parts in cars, airplanes, trains and electronic devices. In addition, it can be excellent for tooling manufacturing aids, connector housings and covers.

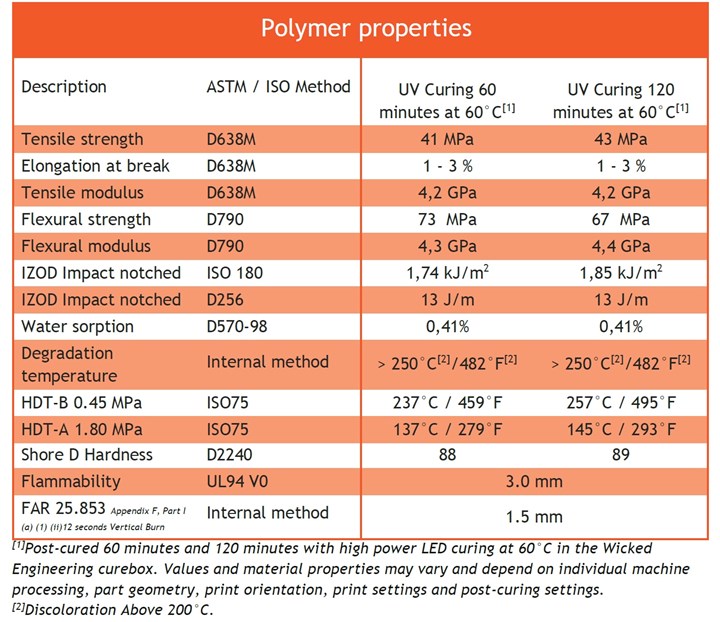

The below tables provide information regarding the mechanical properties of the Liqcreate Flame Retardant HDT:

Flame Retardant HDT Resin for Aviation and Mobility Applications

Liqcreate Flame Retardant HDT resin was tested by the UL94 organization and confirmed in their report that the product has the following flammability rating: UL94 V0 at 3mm. In addition, Liqcreate conducted an internal test method guided by the FAR 25.853 (Appendix F, Part I (a) (1) (ii)12 seconds Vertical Burn) testing methods which resulted in a pass at 1.5 mm thickness. These tests are a good basis for further development of applications within the aviation and mobility sector. Additional tests might be required to fully comply with the FAR 25.853 in aviation or the EN-45545 for train parts.

OEM Possibilities for Flame retardant 3D-Printing Resin

For OEM partners, the resin can be rebranded and optimized for different use cases and 3D printers. Alongside its branded resin range, Liqcreate also provides a custom development service, offering nonstandard formulas for specific applications. Through this service, customers can request the development of a polymer possessing precise characteristics, which impact its printing speed, as well as the properties of the resulting part.

As an independent resin manufacturer with R&D facilities, Liqcreate says it is capable of rapidly scaling its production of custom-made resins where needed. Moreover, the standalone nature of the company ensures there is minimal competition or conflict when working with 3D printer hardware manufacturers. This is said to ensure that the firm can work quickly, and get resins to market in quantity, avoiding any issues or delays that would keep clients waiting.

- Learn about a variety of polymers for additive manufacturing in our Polymer zone.

- Check out the latest advances in additive manufacturing for aerospace and automotive applications.

Related Content

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreCan the U.S. Become Self-Sufficient in Aerospace Alloy Metal Powders?

6K’s technology can upcycle titanium and nickel-alloy parts into additive manufacturing powder. Here is how the circular economy helps national security.

Read More6 Reasons Space Exploration Will Need Additive Manufacturing

There are at least half a dozen ways 3D printing will contribute to space travel, research and habitation — and in some cases it already is. Insights from seminar focused on manufacturing challenges for the space sector.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More