EOS, Volkmann Collaborate on Automated Powder Transfer Solution

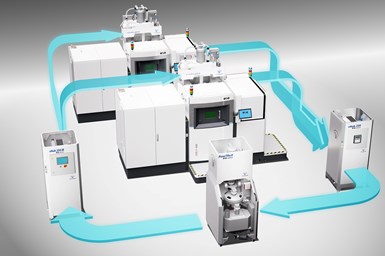

The Volkmann EOS Edition seamlessly integrates with EOS 3D printers.

3D printer manufacturer EOS and metal powder conveying equipment manufacturer Volkmann are partnering to integrate their technologies. As part of the global partnership, EOS will offer an EOS Edition line of Volkmann’s closed-loop and stand-alone, automated metal powder management systems which are specifically engineered for seamless, easy integration with the EOS M 400 series metal additive manufacturing (AM) systems.

The central metal powder management systems automatically control (1) the transfer and loading of material from storage into one or more 3D printers; (2) the capture and sieving of excess powder for reprocessing; and (3) the automated vacuum drying of metal powders. Buffer storage units and other accessories are also available with the new systems.

The systems are available in North America from both EOS North America and Volkmann USA. The EOS Edition may operate as a fully enclosed, sealed circuit to eliminate metallic dust from the workplace, safeguard workers from potential exposure, and protect the metal powders from ambient moisture and contamination. The scalable systems may be operated unattended, 24/7, and controlled and monitored remotely.

“Our new systems provide EOS end users with a complete, plug-and-play, automated powder handling solution that can scale as their production needs increase,” says Christian Mittman, director of advanced solutions for Volkmann. “This is a logical next step in our close relationship with EOS, and one that we feel will benefit EOS customers with faster, safer, more reliable printing and consistently high-quality printed parts.”

Related Content

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

-

Additive Manufacturing Production at Scale Reveals the Technology's Next Challenges: AM Radio #28

Seemingly small issues in 3D printing are becoming larger problems that need solutions as manufacturers advance into ongoing production and higher quantities with AM. Stephanie Hendrixson and Peter Zelinski discuss 6 of these challenges on AM Radio.