Dimensionics Density Offers Automated Density Determination for AM-Produced Parts

Formnext 2023: Dimensionics Density’s automatic density determination technology provides automated, accurate and repeatable density determinations for additive manufacturing production.

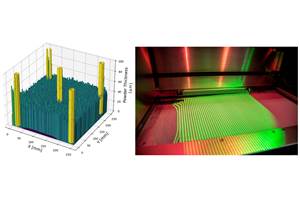

Dimensionics Density has a range of tools that can easily determine the density of freeform parts and highly complex AM parts, and can measure density repeatably to 0.001 g/cm3. Photo Credit: Dimensionics Density

Dimensionics Density’s automatic density determination technology provides automated, accurate and repeatable density determinations for additive manufacturing (AM) production settings. The company’s density determination technology enables manufacturers to reliably test the density of AM-produced parts, and thus reinforce the disruptive position of AM in modern production settings.

As AM production technology stimulates design freedom for part complexity, it can also make density determination more difficult when using traditional density determination technologies such as micrographs, computed tomography and the manual Archimedes method.

It is said Dimensionics Density’s solutions can easily determine the density of freeform parts and highly complex AM parts, and can measure density repeatably to 0.001 g/cm3. It uses the Archimedes method, but does so in combination with modern automation technology, thereby eliminating issues associated with manual intervention and environmental conditions.

In the Dimensionics Density system, samples to be measured are placed in a special component carrier, which is provided with openings on the underside. These component carriers are transported through the system by an axis robot and thus lowered centrally and precisely onto the scales themselves. On the scales, a lift-out rack with pins is placed, which lifts the component over the openings in the component carrier and thus lifts the component out of the carrier.

“The automated handling eliminates human influence on the measurement, as the parts are always placed identically onto the scales. The scales are designed to be insulated from vibration,” says Philipp Pruesse, head of sales at Dimensionics Density. “In addition, all ambient conditions such as temperature, air pressure and water temperature are recorded via climate sensors, and their influence on the measurement result is taken into account directly in the evaluation algorithm when determining the density.”

The density determination technology is designed to work precisely with automation in the AM process chain. Also, the technology is nondestructive, so it can be used to verify parts that conform to density requirements and those that don’t in a speedy, precise and cost-effective manner.

This automation in the AM process chain not only enhances efficiency but also ensures consistency and precision at every stage of production. From design optimization to material handling, postprocessing and, of course validation, automation streamlines workflows, reduces human error and accelerates production cycles, making AM a more and more viable production technology.

The role of validation and quality control is critical, as AM’s unique layer-by-layer fabrication process demands rigorous testing and inspection protocols to guarantee the structural integrity and performance of printed parts, especially when employed in industries such as aerospace and health care, where safety and reliability are paramount.

- Learn more about Dimensionic’s Density Determination Platform as a Fraunhofer-commissioned study gives high marks to this automated density determination solution.

Related Content

Renishaw and Plastometrex Collaborate to Increase Precision, Efficiency of AM Mechanical Property Analysis

Plastometrex’s PLX-Benchtop facilitates rapid, direct testing on different sections of additively manufactured parts, delivering comprehensive stress-strain curves in minutes to provide a more precise evaluation of a part’s mechanical properties.

Read MorePhase3D’s True Layer Thickness Measurement Certifies Uniform Distribution for Every Layer of the Build

The True Layer Thickness tool kit provides objective measurement data to inspect every build in real time.

Read MoreInspection Method to Increase Confidence in Laser Powder Bed Fusion

Researchers developed a machine learning framework for identifying flaws in 3D printed products using sensor data gathered simultaneously with production, saving time and money while maintaining comparable accuracy to traditional post-inspection. The approach, developed in partnership with aerospace and defense company RTX, utilizes a machine learning algorithm trained on CT scans to identify flaws in printed products.

Read MoreNikon Acquires Avonix Imaging

Nikon aims to strengthen its X-ray digital inspection solutions by combining its rotating target X-ray sources and proven software with Axonix Imaging’s expertise in the design of configurable systems, controls and product handling.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More