Nikon Acquires Avonix Imaging

Nikon aims to strengthen its X-ray digital inspection solutions by combining its rotating target X-ray sources and proven software with Axonix Imaging’s expertise in the design of configurable systems, controls and product handling.

Share

Read Next

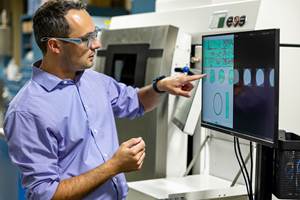

Nikon Americas Inc., the U.S. subsidiary of Nikon Corp., has purchased the U.S. company Avonix Imaging (Maple Grove, Minnesota), which since 2015 has been a strategic X-ray computed tomography (CT) equipment manufacturing partner to Nikon Industrial Metrology Business Unit (IMBU). As part of the acquisition process, Avonix Imaging LLC has become Avonix Imaging Inc.

As a long-established imaging inspection services provider that uses systems from Nikon for both X-ray/CT 3D and 2D inspection, Nikon says Avonix has a wealth of technical expertise using X-rays to investigate the interior as well as the exterior of industrial components. Much of this knowledge has come through joint development projects with Nikon and, in particular, through the manufacture of cabinets and manipulators used in large-envelope CT systems sold by Nikon IMBU worldwide.

“Merging the respective strengths of our companies will reinforce our position as market leader in 3D and 2D X-ray inspection and measurement,” says Tadashi Nakayama, corporate vice president, general manager of the IMBU. “It will massively enhance our ability to deliver best-in-class, next-generation solutions to manufacturing industry.”

In the run-up to making Avonix a wholly-owned subsidiary, Nikon says it worked intensively with them to develop and build new X-ray CT systems with medium to large inspection envelopes. “We recently launched a new model that realizes the largest imaging area for a single-piece cabinet in the industry,” Nakayama adds. “Work on expanding this revolutionary machine series and other new products is continuing apace."

Nikon and Avonix have been successfully working together for the past eight years to jointly develop, build, sell and provide services relating to CT systems for large-scale inspection.

“Nikon’s proprietary rotating target X-ray sources and proven software combined with our expertise in the design of configurable systems, controls, and product handling create a customized experience for our clients, which can contribute to their efficiency and profitability,” says Brian Ruether, Avonix co-founder and co-managing director.

Together, the two companies aim to further advance the development of new products going forward, while enhancing the business by leveraging the customer experience, especially in the automotive and aerospace industries.

“The historical collaboration between Nikon and Avonix has been rooted in the goal of mutual success for all involved, including partners, vendors and, of course, our customers,” says Jeff Diehm, co-founder and co-managing director of Avonix. “It is no coincidence that the goal of mutual success is at the heart of Avonix’s ACE Core Values (authenticity, competency and empathy). The merger will result in enhanced value through the release of new and innovative products. We are excited to take our long-standing strategic relationship to the next level.”

- Last year, Nikon invested in Hybrid Manufacturing Technologies, an additive manufacturing company which successfully created an approach that enables users to integrate additive tools onto any platform. Read how HMT’s technology enables users to take full advantage of the additive manufacturing process by unifying multiple complementary technologies in one setup.

- Nikon also launched a friendly takeover for SLM Solutions last year. Learn how the SLM management and supervisory boards fully supported the transaction and takeover offer.

Related Content

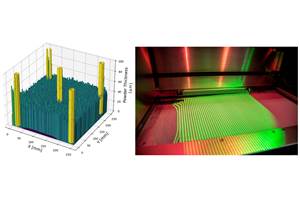

Inspection Method to Increase Confidence in Laser Powder Bed Fusion

Researchers developed a machine learning framework for identifying flaws in 3D printed products using sensor data gathered simultaneously with production, saving time and money while maintaining comparable accuracy to traditional post-inspection. The approach, developed in partnership with aerospace and defense company RTX, utilizes a machine learning algorithm trained on CT scans to identify flaws in printed products.

Read MoreRenishaw and Plastometrex Collaborate to Increase Precision, Efficiency of AM Mechanical Property Analysis

Plastometrex’s PLX-Benchtop facilitates rapid, direct testing on different sections of additively manufactured parts, delivering comprehensive stress-strain curves in minutes to provide a more precise evaluation of a part’s mechanical properties.

Read MoreDimensionics Density Offers Automated Density Determination for AM-Produced Parts

Formnext 2023: Dimensionics Density’s automatic density determination technology provides automated, accurate and repeatable density determinations for additive manufacturing production.

Read MorePhase3D’s True Layer Thickness Measurement Certifies Uniform Distribution for Every Layer of the Build

The True Layer Thickness tool kit provides objective measurement data to inspect every build in real time.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More