Chromatic’s RX-Flow 2500 Features Compact Workspace

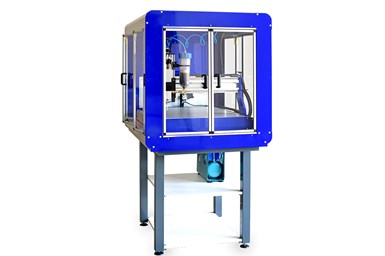

The RX-Flow 2500 printer has a more compact workspace of 348 × 543 × 194 mm (13.7 × 21.4 × 7.63"), while maintaining the cost efficiency, speed and quality output of the larger RX-Flow models.

Chromatic 3D Materials, a 3D printing materials and technology provider, has expanded its RX-Flow printer range for printing thermoset polyurethane parts with the addition of RX-Flow 2500. The printer has a more compact workspace of 348 × 543 × 194 mm (13.7 × 21.4 × 7.63") while maintaining the cost efficiency, speed and quality output of the larger RX-Flow models.

RX-Flow 2500 is suitable for manufacturers that wish to print durable, flexible parts at low cost by forgoing molds and minimizing waste. This smaller unit fits nicely into the range of affordable printers for printing standard industrial polyurethane parts as well as multimaterial parts, overmolded parts and parts that are printed directly onto fabric, metal and other substrates. It is also often more cost effective and faster than building molds for small- and medium-size production runs or prototypes. Moreover, the printer technology minimizes material waste, saving some customers up to 90% in material costs versus traditional production technologies.

With RX-Flow 2500, manufacturers can also increase speed to market by quickly iterating new designs and printing finished parts in various sizes and a variety of specifications. The unit has print speeds of 5,100 mm/min. along the X and Y axes and 3,000 mm/min. along the Z axis. It can print polyurethane parts at a rate of 1 part/10 seconds depending on the shape and size. For example, the company printed more than 300 O-rings in one hour for a leading provider of components for the HVAC and refrigeration industry.

The printer is designed to print high-quality thermoset polyurethanes for industrial and consumer applications that demand durability and flexibility. Like other RX-Flow printers, the unit works with Chromatic’s printable polyurethanes with Shore A hardness ranging from 50-90. These materials have the same three-dimensional strength and compression set as injection-molded parts.

“RX-Flow 2500 is a compact industrial 3D printer that pushes the boundaries of performance and speed. It empowers manufacturers, researchers and innovators to bring their ideas to life with unprecedented efficiency by accelerating the production process and reducing time-to-market without compromising quality,” says Cora Leibig, CEO of Chromatic 3D Materials.

- Learn more about Chromatic RX-Flow 3D printers for reactive extrusion additive. The RX-Flow printers are a low-cost option for manufacturers interested in testing and implementing industrial 3D printing with more durable, flexible materials than are available with FDM, SLA and other 3D printing technologies.

- Read about Chromatic 3D materials meeting flammability requirements for aerospace industry. NIAR testing shows that multiple polyurethanes 3D printed by Chromatic are compliant with U.S. standards for use in aircraft interiors.

Related Content

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

Drones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.