Materialise Opens Medical 3D Printing Facility

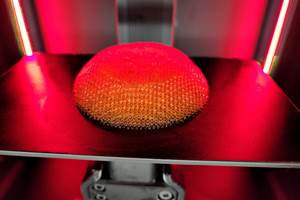

At the new facility in Plymouth, Michigan, Materialise specializes in the 3D printing of personalized titanium cranio-maxillofacial (CMF) implants for more patient-specific care.

Materialise is working to accelerate the delivery of patient-specific medical implants to patients in the United States with the opening of a new 3D printing facility in Plymouth, Michigan. Surgeons are increasingly embracing 3D printing solutions as they recognize the added value it brings to personalized patient care, including more predictable and accurate surgical outcomes, and time savings during surgery.

At the new facility in Plymouth, Michigan, Materialise specializes in the 3D printing of personalized titanium cranio-maxillofacial (CMF) implants. CMF implants are used for facial reconstructive surgery. Until now, Materialise manufactured titanium CMF implants solely at its 3D printing facility in Belgium. With a dedicated metal 3D printing facility in the U.S., the company can respond to surgeons’ needs with greater reliability while significantly reducing the delivery time of fully personalized implants to hospitals across the U.S. This expansion of capabilities complements Materialise’s existing production of 3D printed surgical guides and anatomical models in the United States.

“With the opening of our new metal 3D printing center in the U.S., we bring personalized care closer to U.S. patients,” says Brigitte de Vet, vice president of medical at Materialise. “The power of 3D printing paired with our three decades of experience in 3D planning and medical manufacturing, allows us to accelerate the delivery of personalized medical implants. We take pride in leading the charge to revolutionize patient-specific care and with our dedicated facility in Michigan we further enhance personalized care in the United States."

The advent of technologies such as 3D printing and advanced visualization techniques has transformed personalized patient care. Patient-specific 3D printed medical solutions include anatomical models for diagnostic purposes, and surgical guides and implants to enhance accuracy and efficiency. These solutions are designed to bolster surgeons’ comfort before and during surgery, leading to more predictable and accurate surgical outcomes. As a result, surgeons increasingly adopt 3D printing as part of their medical practices to bring personalized care closer to patients and to reduce overall costs.

Materialise has more than three decades of experience in developing medical solutions and offers a comprehensive range of 3D printed guides and implants. The company produces 280,000 personalized 3D printed instruments and implants per year, including 160,000 for the U.S. market.

The company says it has pioneered numerous groundbreaking medical 3D printing applications. In 2017, it introduced one of the first personalized CMF implant portfolios in the U.S. In 2021, its 3D planning and 3D printed instruments played a pivotal role in the world’s first simultaneous double hand and face transplant that was successfully performed at NYU Langone Health in Manhattan, New York.

- Read about EOS’ adoption of Materialise CO-AM Software Platform to improve internal additive manufacturing efficiency. The CO-AM platform is designed to enhance traceability and connectivity in the company’s internal additive manufacturing processes.

- Learn how GKN Aerospace and Materialise are partnering to propel additive manufacturing in aviation. Materialise supported the delivery of the additively manufactured wing tip for Eviation’s Alice, the world's largest all-electric aircraft, which made its maiden flight in 2022.

- Find out how Materialise’s surgical guides illustrate the promise of mass customization. The company’s interconnected software systems enable production via additive manufacturing of a product tailored to individual surgeries.

Related Content

Production AM Demands Process and Procedures — More Machines Will Come Later

Arch Additive has transitioned to full production of implants made through electron beam melting. The transition has involved practices and personnel, not equipment. As customer products win approval and go to market, here are 5 operational moves the AM implant manufacturer has made.

Read MoreStratasys, CollPlant Unite Technologies for Industrial-Scale Bioprinting of Tissues, Organs

The joint development and commercialization agreement will initially focus on development of a bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity.

Read MorePrinterPrezz/Vertex Manufacturing Rebrands to Zeda

The rebranding is said to reflect the company’s “Z to A” approach, which means it starts first with the customer in mind and ends with a product.

Read MoreMore Affordable Suture Anchors 3D Printed from PEKK: The Cool Parts Show #60

Selective laser sintering (SLS) of polyether ketone ketone (PEKK) is being used to produce medical implants that are more cost effective and perform better than their conventional counterparts. We highlight fasteners known as suture anchors in this episode of The Cool Parts Show.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More