Sand

America Makes Announces IMPACT 2.0 Project Call Worth $6.6 Million in Funding

The deadline for the first set of project proposals is May 29.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

WatchLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreStratasys and Desktop Metal to Combine in Approximately $1.8 Billion All-Stock Transaction

Merger looks to deliver industrial polymer, metal, sand and ceramic solutions from design to mass production.

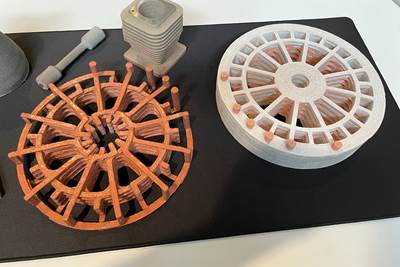

Read MoreMultimaterial 3D Printing with Conventional Powder Metallurgy

Unbound sand serves as temporary, reusable molds for metal powders in Grid Logic’s 3D printing process.

WatchOptimized Castings, Fast Turnarounds with Sand 3D Printing

IMTS 2022: ExOne’s S-Max Flex pairs industrial robots with an end effector printhead design that deposits binder into a 1,900 × 1,000 × 1,000 mm (74 × 39 × 39") telescoping build box that grows as the parts are built layer by layer.

Read MoreDesktop Metal’s Robotic Additive Manufacturing System for Sand Printing

The ExOne S-Max Flex system use single-pass jetting technology to deliver 3D printing at high speeds for low-cost parts.

Read MoreBinder Jetting Is Also a Tooling Technology

A portfolio of 3D printing solutions involving infiltrated sand and metal covers tooling needs for casting, thermoforming, molding and composites.

Read MoreFinland Sees Swifter Castings Through Hybrid Manufacturing

Combining sand 3D printing with casting has enabled Hetitec Oy to meet the underserved small-batch Finnish casting market — in some cases, producing high-priority parts in under a week.

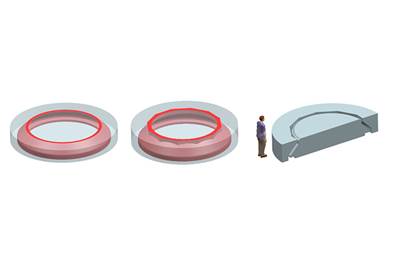

Read MoreResearch Partners Building World’s Largest Sand Binder Jetting Printer

3D printing provides flexibility to produce large turbine components near offshore wind projects, lowering transportation costs and offering environmental benefits.

Read More