Fathom Manufacturing offers production services using a variety of technologies including CNC machining and injection molding, but additive manufacturing plays a key role for design iteration, functional prototyping, and bridge and full-scale production. The company’s Fremont, California, Technology Center is now home to the first SVP 3D printer from Evolve Additive Solutions in commercial use, bringing another option for additive manufacturing. The machine uses STEP (Selective Thermoplastic Electrophotographic Process) to build high-quality polymer parts using the same materials as injection molding. This video explores how the system works and ways that Fathom is applying it.

Related Resources:

- Fathom Manufacturing’s Fremont, California, facility and its role within the contract manufacturing business

- Evolve Additive Solutions’ SVP 3D printing platform and its potential to compete against injection molding

Transcript

3D printed parts using the same thermoplastic that you can injection mold. It's possible with this technology from Evolve Additive Solutions. I'm Stephanie Hendrixson with Additive Manufacturing Media.

I'm here at Fathom Manufacturing’s Technology Center in Fremont, California. This is one of multiple locations that the company has. Here in Fremont, they have the first Evolve Additive Solutions SVP machine that's being used for commercial applications.

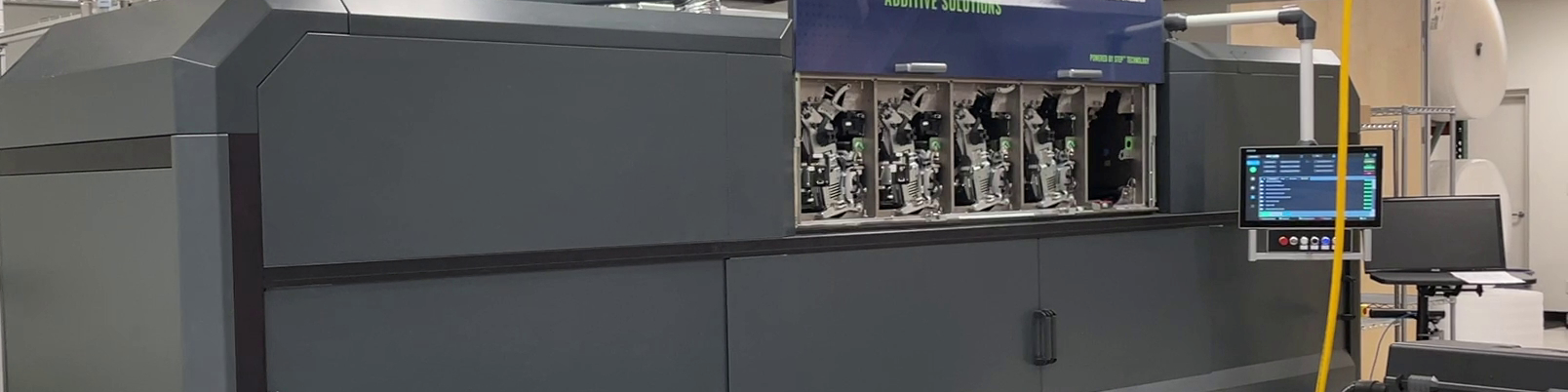

This 3D printing technology is based on 2D printing. It is built on the NexPress platform from Kodak, a digital color press designed for high-volume printing of brochures, posters and other paper products. Evolve’s SVP machine uses Selective Thermoplastic Electrophotographic Process, or STEP to layer 2D images printed in polymer rather than ink in order to build up three-dimensional parts.

Inside the machine, there are multiple engines. In the case of a 2D printing system, these would represent CMYK inks. But here they are used for different types of materials. Right now, Evolve is just offering a support material and a part material, but you could add additional types of materials, additional colors, and expand out up to five independently operated engines.

Each engine is basically a toner cartridge that transfers the image of the layer onto a belt, which is then aligned with the build plate and transfused onto the build. They are depositing both the support material and the part material at the same time, kind of building up a block of parts.

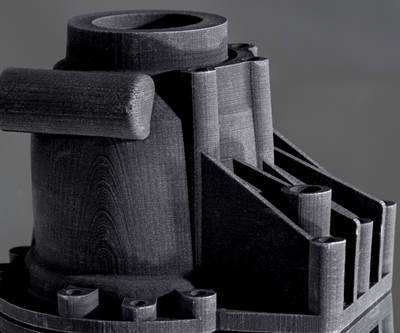

The support material acts like a mold. It encases all of the parts, helps to improve the surface finish and get really really fine details. Every layer is 13 microns thick, and this machine can print up to a height of a couple of inches. Builds can be done in just a couple of hours.

As the material is being deposited, each image is scanned and a topographical image is being captured. The system is looking at the height of the material that has been deposited. If the layer is too low, it will deposit more material on the next pass, and if it's too high, it will reduce the amount of material until everything is brought within the expected range.

When the build is complete, the entire block is removed. It can be popped off of the build plate, which is then reusable, the entire block goes into a wash station where the support material is removed over a period of a day or so. And the parts are typically ready to go right out of the wash station.

Fathom is finding a lot of utility for this system for parts that need fine features, those critical details and really, really good surface finish. They're seeing the Evolve platform as a way to prototype parts that might eventually go to injection molding, but also as a way to do bridge production and full-scale production through this system.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreSolving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreRead Next

Can Additive Manufacturing Compete With Conventional Manufacturing on Cost?

When it can, says Evolve, the design advantages of AM find their way in. The company is beginning to ship its high-speed AM system for polymer part production.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreAM 101: Selective Thermoplastic Electrophotographic Process (STEP)

Learn about Selective Thermoplastic Electrophotographic Process (STEP): how it works, the comparative benefits and where it is leading additive production in the future.

Read More

.jpg;width=70;height=70;mode=crop)