The Post-Production Challenge for Additive Manufacturing

The benefits of controlling postprocessing operations for additively produced parts reach beyond cost.

There’s a phrase that is becoming more common as industrial additive manufacturing advances from prototyping into production. It’s typically heard when Company A’s additively manufactured part is shipped to Company B for postprocessing and, somewhere along the way, a flaw in the part is discovered. That phrase is “finger-pointing,” and it usually surfaces when each company attempts to establish the genesis of the flaw. More often than not, finger-pointing is the manifestation of a lack of process control throughout the entire production chain for a finished AM part—especially a metal part. Each time postprocessing is outsourced, for instance, the potential for miscommunication and muddied expectations creeps in.

Of course, end-to-end, single-source production of high-value functional AM parts is still out of reach for many manufacturers due to the multiple steps this might require. But Incodema3D—a growing, full-service AM manufacturer based in Ithaca, New York—is not like most manufacturers. Its story exemplifies not only AM’s emergence beyond rapid prototyping, but also serves as yet another roadmap for the ways and means by which a more traditional manufacturer can enter the market.

The challenge, according to Incodema3D founder and CEO Sean Whittaker, “was to figure out AM’s puzzle.”

Chance for Productive Conversations

Incodema3D, housed in a spotless and sprawling 60,000-square-foot facility in Freeville, New York, works across numerous AM platforms and materials, but specializes in direct metal printing for prototypes and production quantities of parts. While companies in the aerospace sector represent Incodema3D’s primary customers, the company also functions as a contract manufacturer for the defense and energy industries, as well as motorsports and medical. In 2015, Incodema3D owned four metal AM machines. Today, just two years later, that number is 15 AM machines and 25 postprocessing CNC machines. The company aims to be the country’s preeminent production contract manufacturer in the additive space.

“We don’t just print parts; we manufacture parts to print.”

But Incodema3D, both as a concept and a company, wouldn’t work as a stand-alone. Since the parts it prints are usually high-value adds—a 3D-printed circuit board heatsink for a jet, for example—they’re typically quite expensive. With that, Whittaker explains, if Incodema3D were to print a part, and then contract with another shop or send it back to the aero OEM to finish processing and machining, and suddenly there’s a problem with the part, “that’s where the finger pointing begins,” he says. “If you don’t have a cohesive supply chain set up, and someone tells you the part wasn’t printed properly, the process doesn’t work.”

Instead, Incodema3D is the newest of four companies that compose The Incodema Group, which Whittaker founded in 2001 after working for years as a mechanical engineer at NCR Corp. While he had been introduced to stereolithography in the 1980s, Whittaker’s engineering experience was steeped in traditional manufacturing methods. In fact, it was Whittaker’s innovation that sped up the design and manufacturing of parts produced from sheet metal that allowed him to begin the original Incodema, which today still serves as a sheet metal prototyping company that employs laser and water-jet cutting, sheet-metal stamping, CNC machining, and other traditional manufacturing processes for the automotive and biomedical industries.

In other words, Incodema3D represents the last piece of that complex AM puzzle. Each of the other three pieces—Incodema, Engineering Manufacturing Technologies (a production metalworking facility in nearby Endicott), and Newcut Photo Chemical Etching (seemingly an outlier, this company employs photochemical milling to improve surfaces on AM parts)—could and did operate successfully as part of the collective without the addition of the last puzzle piece. On the other hand, Incodema3D is able to meet its promise of being a single-source producer of functional AM parts—and serve as the last piece of the puzzle—only because the other three pieces are in place.

“One of our mottos is, ‘We don’t just print parts; we manufacture parts to print,’” Whittaker said during a keynote speech that preceded a recent tour of Incodema3D’s facility. While the motto itself has a slight chicken-or-egg conundrum baked into it (3D printing is part of additive manufacturing and vice versa) nestled within that motto is exactly what sets Incodema3D apart. “We brought additive manufacturing into a core manufacturing environment with multiple toolsets—CNC, precision sheet metal, photochemical machining and other manufacturing capabilities—versus the typical methodology of a printing company realizing that you need all of these ancillary processes to complete a part,” Whittaker says. “So we took a sort of backwards approach, which for us was only logical.”

The Life of a Part

At a recent seminar presented by GE Additive, one of its engineers stated that, out of all of the line items that compose the final cost of a part—labor, operating expenses, machine depreciation, scrap costs, machining costs, part material costs, solid material waste and powder waste—postprocessing often represents nearly 30 percent. If a company owned and controlled the postprocessing operations, however, it could realize significant advantages that go beyond mere cost considerations.

Of course, what we’re talking about here is vertical integration. The Incodema Group—with its hundreds of employees and tens of millions in capital investment—came to its current level of integration gradually. It took Whittaker and his partners 16 years to place that final puzzle piece, and it was 16 years of methodical planning, and forming strategic partnerships with academia (Cornell University) as well as seeking and receiving tax incentives from the state of New York, that has allowed Incodema3D to achieve vertical integration to a very high level.

How high?

Let’s look at the life of a part.

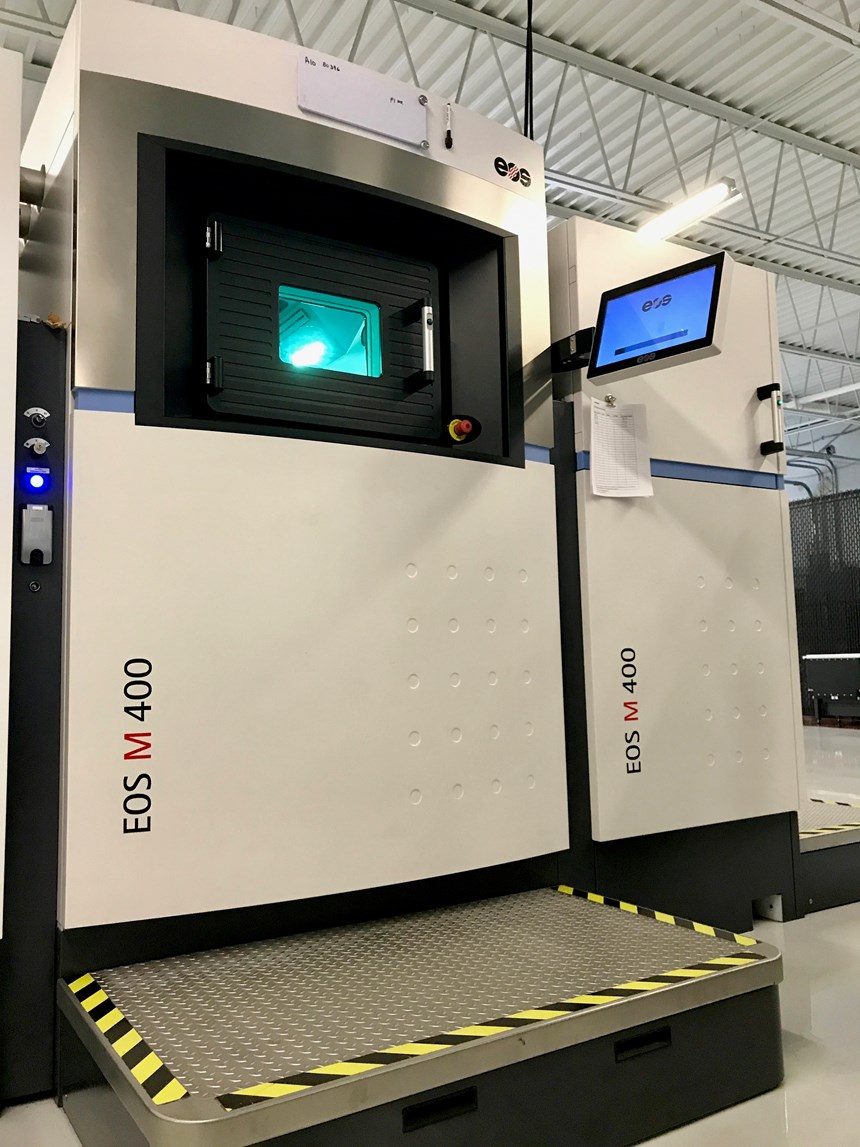

One of Incodema3D’s typical orders is for a heat exchanger component—a heatsink—which it prints on an EOS M400. The component, made of AlSi10Mg aluminum, contains a series of internal fins of a size and an overall configuration that can only be manufactured additively. The part’s purpose is to cool circuit boards in an aerospace application, and the proximity of the circuit board’s components to the actual heatsink requires precise dimensions and a very tight tolerance. Of course, this means that the entire surface of the part must be machined. With service applications available within The Incodema Group (IG), workers could easily drive the part to a nearby IG facility for additional multi-axis machining work. But since multi-axis machines can only address the exposed surfaces of the part, another solution is needed. So the part is instead driven (on IG-owned vehicles) to Newcut Photo Chemical Etching, which employs a photochemical milling process to improve the surface finish (and thus the flow rate of the air passing through the part) and remove loose material from inside the part.

Worth mentioning: After the print run is finished, Incodema3D scans the geometry to ensure it has created a good base part. An overlay comparison to the CAD geometry is added to the scan, and that dataset is delivered to an IG machinist, who uses the data to start a basis (the confidence-level metrics used for part certifications within aerospace). The machinist then performs thermal processing on the part from the supplied information, as well as a final laser scan to use as inspection data.

In the end, that part hits nearly every aspect of IG’s operations.

“Without that ability,” Whittaker says, “we’re kind of throwing a part over the wall and hoping that (the machinist) catches it, and our likelihood of success is very limited. It’s taken years for our additive programmers and our CNC programmers to develop that understanding—where we need to add stock on and add material in certain areas. We may need to use workholdings, so we’ll print an extra feature on a part to be able to hold it during the machining operation. And that workholding area is removed or cut off from the part. So there’s a very long process chain, but having it all integrated into our operation is a major advantage.”

Whittaker points out that for all of Incodema3D’s successes and capabilities, it was just three years ago that the company had only three additive parts in production for customers. Today it has 15. A year from now he expects that number will be in the hundreds.

“Two or three years ago, the dialogue of accepting AM technology in the industry almost didn’t exist. And today, we’ve tried, we’ve proven, we’ve had successes, and now we’re getting to the point where they’re now embracing that technology. That’s the challenge we’re in. We’re production ready; our customers aren’t quite there. We may not be using the full capacity of this facility today, but very soon, we will. Very soon.”

Related Content

How Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreRead Next

In Additive’s Evolution, Aerospace Proves the Fittest

As additive manufacturing shifts from prototypes to production, one industrial sector is ahead of the curve.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More