The Possibilities of Electron Beam Additive Manufacturing

With dual-wire material feed now allowing for options including blended metal alloys, the metal-deposition process for large-part additive manufacturing continues to forge ahead.

The view that says additive-manufactured metal parts are necessarily small parts is a view that assumes a particular type of additive machine. That is, that view assumes a powder-bed machine—a machine in which a laser or electron beam moves through a stationary bed of powder metal to create each incremental layer of the part. But this is not the only way to do metal additive. An alternative involves machines in which the material is not in a bed, but instead actively fed. The material supply travels with the beam head, so the size of the part is limited only by the travels of the machine.

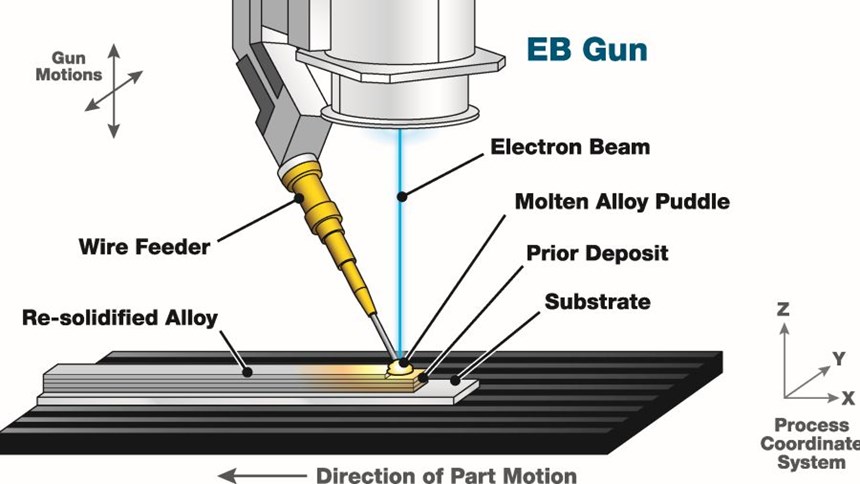

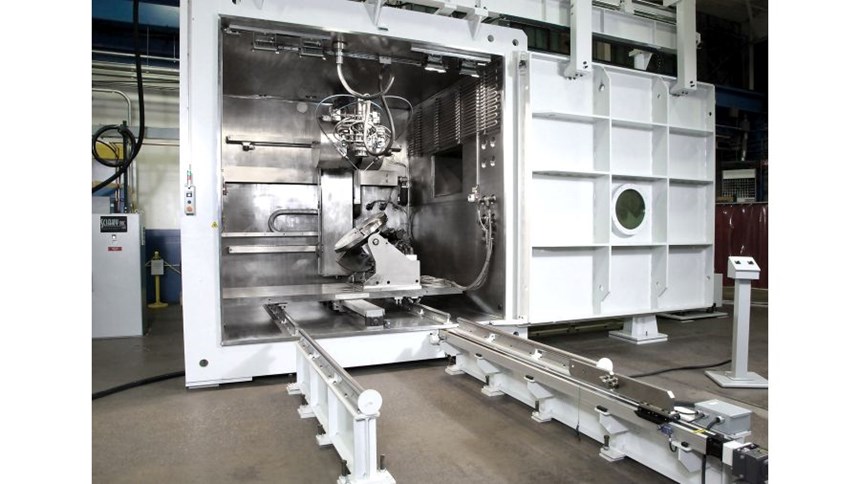

Sciaky, based in Chicago, Illinois, is an example of a company making systems for achieving additive manufacturing through this kind of material deposition. In this company’s process, which it calls Electron Beam Additive Manufacturing or EBAM, wire feedstock is the raw material, and this wire is fed into the path of an electron beam to additively build parts and features. This method of material deposition is an adaption of welding systems the company has produced for decades. Proprietary closed-loop control over parameters such as temperature and material flow allows it to build 3D structures. The company introduced this variety of additive manufacturing in the early 2000s, and it reports that its additive machines (used by the company itself or by its customers) have so far deposited more than 18,000 pounds of titanium alone.

The contrast between this company’s additive process and a powder-bed process is worth making. Because EBAM lays down material in a bead, it does not produce forms as finely detailed or as near to net-shape as what a powder-bed process can achieve. However, the deposition process permits larger forms, as mentioned, and thanks to the deposition rate of the bead, the EBAM process is faster as well. A cylindrical test part that would have taken 12 hours to build with a powder process took 10 minutes to build with EBAM (see photo). Change-over between jobs is also faster on the EBAM machine, because material change-over requires just swapping in a different spool of wire. Again, the comparison with powder-bed is worth making, but it is germane only to a point. Ultimately, these two different additive machine types will be used in distinct and separate applications.

The far more meaningful comparison is actually between EBAM and forging. Forging is the typical way that near-net-shape forms are made for large parts made of hard metals such as titanium and nickel-based alloys. While forging is a long-established process with decades of application research behind its use, EBAM is young by comparison, and still proving itself. It is also still improving, Sciaky says. The company says its additive process now delivers material integrity and consistency that are superior to casting and rival the properties of forgings. Today’s forging buyers are apt to accept defects in forgings that are greater than what they would accept in an EBAM part because the behavior of a forging is better understood. But the advance of the material-deposition process implies that the day will eventually come when parts made this way are in routine use alongside forgings as another option for creating the preforms of large components.

When that day comes, how will production processes change? And how will parts themselves change, once material-deposition AM becomes a more common manufacturing method for large parts? I recently had the chance to speak about this with Kenn Lachenberg, Sciaky’s application engineering and new product development manager, and Robert Salo, technical sales, along with the company’s general manager Mike Riesen. In terms of the ongoing advance of the EBAM process, one notable factor these men point to is the development of systems that feed the material from two coils of material instead of one. The possibilities of the dual-coil system go well beyond just doubling the rate at which material can be applied, they say.

The Needs of Forging

In comparing forging and EBAM, the obvious difference is this, says Lachenberg: Forging needs tooling. Specifically, forging needs a die. Because EBAM avoids the need to create this tool, it can offer a considerable lead time advantage. “Lead time is where we typically win,” he says.

The additive process also generally wins when it comes to the cost of subsequent machining, Riesen stresses. This point is becoming increasingly important. Material input and material removal represent two of the most significant remaining opportunities for production cost savings by major OEMs. Forging and EBAM are both near-net-shape processes, but EBAM is the “nearer” of these two, leaving less material to be machined. In aerospace, Riesen says machining savings are often the prime factor making the case for additive. OEMs in this sector look at the buy-to-fly ratio, the ratio of the gross weight of a structure to the weight of the part after machining. On parts well suited to EBAM, the process typically delivers a 50 percent reduction in buy-to-fly, Reisen says. That saves cost two ways: Less material is purchased and less time and expense go into machining it away.

Meanwhile, the shift to additive could also change the very location and organization of production, he says. Forging is a process tied to particular facilities. That is, forging needs a forge. This basic fact has implications for logistics, inventory management and the capacity of the supply chain. EBAM, by comparison, is a process able to be located at various suppliers’ sites. To simplify flow and improve efficiency, EBAM could even be used to make near-net-shape workpieces at the same site that also includes heat treating, rough and finish machining, and non-destructive inspection, all under the same roof.

One final way additive manufacturing is distinct from forging is found in the way AM offers control over the part as it forms. A forged part is produced through impacts. But an additive part grows incrementally, and Sciaky’s closed-loop control enables parameters affecting its formation to adjust throughout the build. As the mass of the part increases during the build, for example, energy input to the melt pool could adapt to the changing thermal response to maintain consistent part geometry, chemistry and microstructure.

Could this same varying of parameters even be used to tailor the microstructure by design, to build in different microstructure for different purposes in different regions of the part? Almost certainly yes, company leaders say. The design possibilities of additive manufacturing—their own system and others—are only beginning to be explored.

The Promise of Dual-Wire

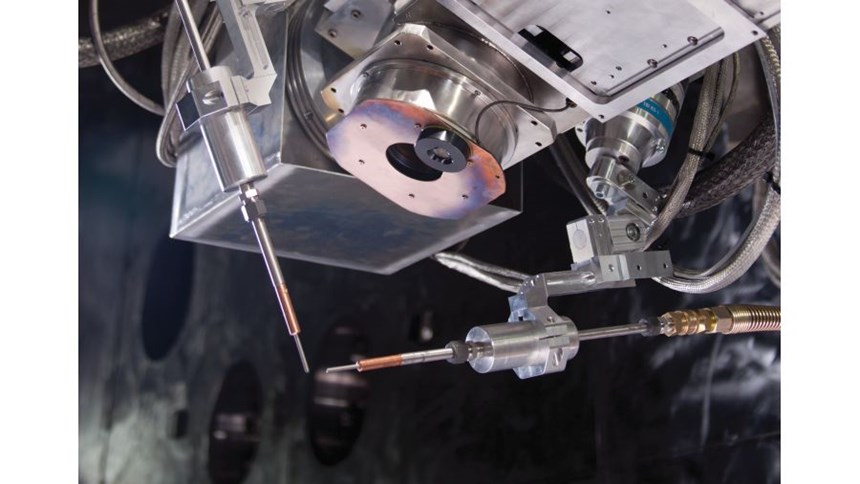

One seemingly straightforward option for the system is particularly significant. Dual wirefeed allows the EBAM machine to deposit material from two independently controlled spools of wire simultaneously, potentially increasing deposition rate. But throughput is just the beginning of the application. Because of its many potential uses, dual wirefeed might be the enabler to EBAM realizing its full promise, and might even lead to the development of parts that no other process can make.

For example, must it always be the case that the wire-fed process is at a disadvantage when it comes to fine and intricate details? Sciaky’s Lachenberg points out that this limitation might already be surmountable. An EBAM machine could be equipped with large-diameter wire to build the rough form of a large structure, along with fine wire to then add intricate features.

But perhaps the most interesting possibility of all is this: What if the two wires are two different alloys? The metals could then be blended into the part at varying rates, creating a material gradient in the part that achieves certain metal properties within the bulk of the part and different metal properties near a critical surface. The different materials could even be blended to create a proprietary alloy developed (and patented) by the machine user.

This possibility begs the question of what the greatest promise of metal additive manufacturing really is. When discussion turns to the design freedom of AM, geometric freedom is what we usually imagine. But the design freedom also includes material freedom. Likely no other process permits the user to apply and experiment with combinations of metals the way a material-fed additive manufacturing process does.

That fact opens the way to a variety of potential users for this machine. The manufacturer seeking single-site process flow—creation of near-net-shape parts in the same facility as machining and assembly—is just one scenario. Another is use by a material supplier. Along with supplying bar and billet of standard metal, this supplier might also offer special alloys developed internally using the additive machine.

Yet another possibility is use by a forge. The contest between EBAM and forging need not be a contest at all if a single supplier offers both options. Perhaps the ultimate user of this technology might prove to be the forging companies, and the ultimate impact might be to make these companies stronger by giving them an alternative to forging in those case where additive is the more efficient choice.

Related Content

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreAM 101: NanoParticle Jetting (NPJ)

The proprietary process from XJet builds ceramic and metal parts using nanoparticle suspensions. Learn how NPJ works in this introductory article, part of our AM 101 series.

Read MoreAM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More