HAMR Industries supplies 3D printed parts, primarily in copper and aluminum, that are often intended to replace or serve as alternatives to castings and forgings.

Cold spray, the 3D printing process that fires powder particles at high speeds to build parts through deformation rather than melting, offers a number of advantages as an alternative to casting or forging. HAMR Industries, a contract manufacturer located at Neighborhood 91 in Pittsburgh, Pennsylvania, has invested in cold spray equipment from Spee3D and is leveraging this capacity for both parts replacement and new program development.

Founded by Michael Schmitt and Jeremy Schrieber following completion of their doctoral degrees at Penn State University, HAMR Industries was created with an aim toward transitioning early-stage technology into real-world applications. The company’s moniker, HAMR, stands for Highly Advanced Materials Research, and signals the startup’s focus on applying novel materials and innovative manufacturing techniques to deliver parts for use in challenging environments.

HAMR Industries’ primary activities today center on demonstrating the capabilities of additive manufacturing, and specifically cold spray technology, in research & development projects, as well as delivering parts for commercial contracts. Almost all the work involves using AM as an alternative to casting or forging, Schmitt says.

“We are able to achieve near-wrought properties while making very large components,” he says. “Spare parts are the shortest path to production now, but longer term we plan to get in from the start on R&D to make components from scratch.”

Pushing Cold Spray to the Limit

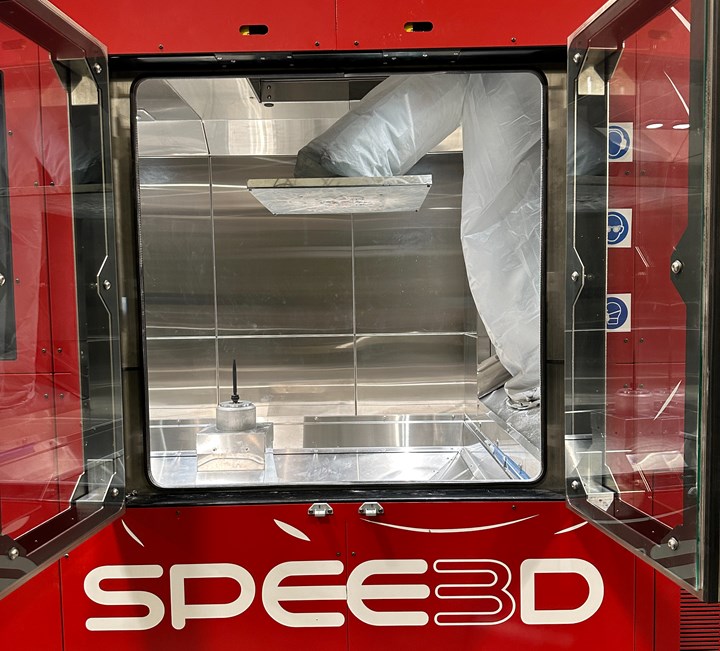

The technology HAMR Industries has chosen for this current and future work is cold spray additive manufacturing, specifically a WarpSpee3D system from Australia-based supplier Spee3D. This platform flips the setup of many other 3D printing technologies, with a stationary cold spray nozzle that sprays material particles at supersonic speeds onto a build plate that is manipulated by a robotic arm.

The WarpSpee3D platform at HAMR Industries is equipped with a Phaser nozzle (lower left) that fires metal powder particles at a build plate held and manipulated by the machine’s robotic arm.

Because the process relies on velocity rather than melting to adhere material, cold spray makes it easier to work with materials that can be difficult to print with laser energy, such as refractory metals and the copper that that makes up most of HAMR’s current work, alongside aluminum and titanium. To support experimentation with harder materials, the company’s printer has been upgraded with a Phaser nozzle from Spee3D that allows the cold spray to operate at increased temperature and velocity, more readily enabling the deformation necessary to build parts from these metals.

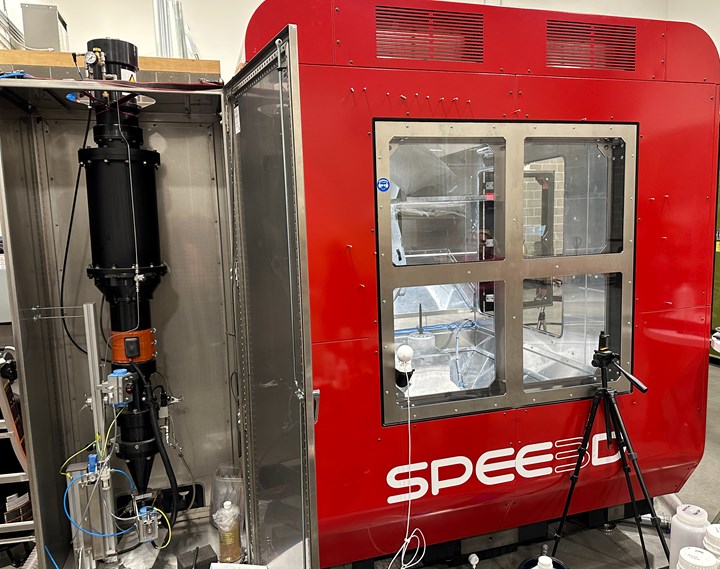

But while the WarpSpee3D system came equipped to meet many of the challenges HAMR Industries is facing, the company has also made modifications to suit its specific needs. Many of the parts HAMR produces are quite large, up to 1 by 1 by 1 foot and larger. The company found that the powder feeder that came with the printer did not have enough capacity to hold the material needed for these builds, necessitating pauses for refills. HAMR developed a larger-capacity feeder that could support these prints from beginning to end, while still fitting in the original cabinet. The original feeder could hold 24 kg of aluminum previously; the HAMR-developed feeder can hold 40 kg of this material — the maximum weight for the robot’s payload as well.

HAMR Industries developed a larger powder feeder for its WarpSpee3D 3D printer, but designed it to fit in the existing cabinet (left). The added capacity has enabled the company to print large components without stopping to refill material.

Part size and weight have also had an impact on the programming of the machine. While producing a very heavy part, HAMR noticed that the robot arm’s movement was less precise than usual.

“The part had a lot of momentum in rotation,” Schmitt says. “Imagine trying to write with a dumbbell in your hand.” That momentum was causing the robot holding the part to overshoot the nozzle, impacting material deposition and ultimately resulting in part failures. Solving this problem involved manipulating the path of the robot to slow down those rotations.

“We never meant to dive into robot programming and kinematics, but that’s what we needed to learn,” Schmitt says. That willingness to go above and beyond, and to make the equipment work for the application, is part of the overall ethos of HAMR Industries. “We’re pushing the envelope of what the OEM’s equipment can do, and was designed to do,” he says, noting that the modifications have been conducted with support and collaboration from Spee3D, which is also benefiting from the lessons HAMR is learning.

Over the long term, HAMR Industries expects to add directed energy deposition (DED) to its 3D printing portfolio as well, as a way to achieve the finer features not currently possible through cold spray.

Cold Spray Parts Under Pressure

Many of those large parts that have necessitated equipment and software modifications were developed for Department of Defense applications, specifically the U.S. Navy and Army. Pressure vessels are of particular interest; components like this are conventionally produced through forging and currently face lead times of up to 12 months.

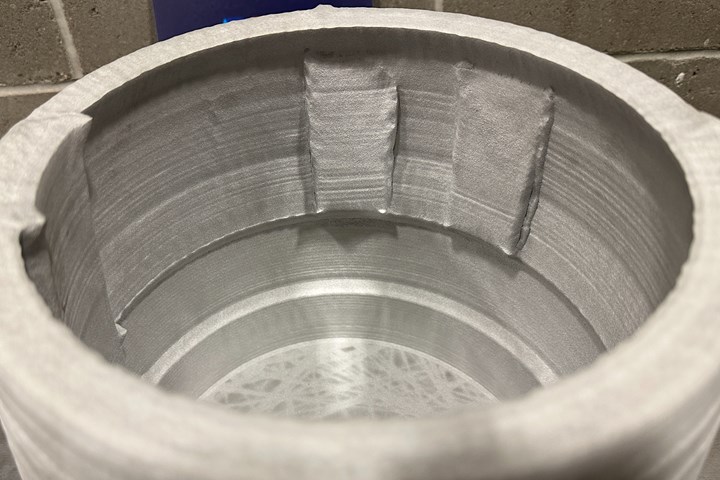

This cylinder was printed from Al 6061 as an analog to a pressure vessel that might be found on an undersea vehicle. Source: HAMR Industries

This cylinder was printed from Al 6061 as an analog to a pressure vessel that might be found on an undersea vehicle. Source: HAMR IndustriesHAMR Industries printed the pressure vessel demonstrator pictured to the right out of 6061 aluminum. The vessel was finish machined and then pressure tested to 1,500 psi (equivalent to a depth of 3,000 feet below sea level). The successful pressure test gave the customer confidence to begin prototyping larger vessels, where additive manufacturing brings significant opportunity to reduce lead times and cost.

A larger pressure vessel demonstrator part that I saw during my visit (interior shown below) illustrates some of these savings. The build took about 21 hours and the final part weighs about 30 kg (and thus required the larger powder feeder described above). This larger pressure vessel demonstrator was developed and produced in just a few weeks, saving considerable time over the conventional supply chain for a component like this.

The time savings comes partly from the fact that the 3D printed demonstrator required significantly fewer operations to complete. The interior of the part includes ribs that would need to be machined from a rough forging in a conventional pressure vessel; here, HAMR Industries was able to simply build them into the part during the print. The ribs are suitable for use as-printed, avoiding the need for additional machining on this feature.

Ribs like this inside a pressure vessel previously would have required forging and machining to achieve. With cold spray, HAMR Industries can incorporate these features as part of the printing process; the ribs can be left as-printed, reducing the finish machining needs on this part just to exterior turning.

In total, a conventionally produced pressure vessel of this size might cost up to $100,000 in machining alone. The 3D printed version required no interior machining and less than $5,000 in exterior turning operations. The demonstrator is one of the largest cold spray parts built to date, and cost less than half of a traditional forging.

This project illustrates both the challenges organizations such as the Navy are facing, and the ways that AM can help to alleviate these difficulties for replacement parts as well as developing new systems.

“It can take 12, 18, 24 months to get a new forging made, and that can eat up most of the timeline of a new program so there’s zero design flexibility,” Schmitt says. “With cold spray, we can try multiple designs — not just go with the safe design — and develop a solution that saves time and cost.”

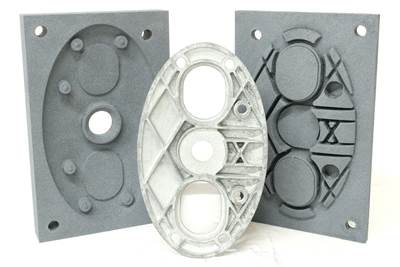

This funnel cover is another Navy submarine application. These components are necessary for the operation of a sub, but are frequently lost in use. It can take 9 to 12 months to source a conventional cover, but HAMR Industries is now able to produce them in just one week.

Demonstrating Expeditionary Manufacturing

While HAMR Industries’ home is at Neighborhood 91, the company is also helping to make expeditionary manufacturing — part production near the point of need — a reality. Near the end of January this year, HAMR Industries shipped its WarpSpee3D system to Norfolk, Virginia, to demonstrate how cold spray additive manufacturing can be applied in the field as part of the U.S. Navy’s Repair Technology Engagement Exercise (REPTX).

As a participant in an REPTX Expeditionary Sustainment and Repair (ESAR) scenario, HAMR Industries collaborated with a team to reverse-engineer a valve analogous to a real system. The team scanned the two-piece valve assembly and HAMR performed DFAM before the 316 stainless steel components (each weighing 10-13 kg) were printed on the cold spray platform. Finally, the parts were heat treated. The entire process from scan through heat treat was accomplished in about 48 hours.

The project demonstrated “the ability of Spee3D’s cold spray additive manufacturing equipment to quickly provide solutions in the field,” Schmitt says. “Importantly, it also showed that our team is able to field this technology in a very capable manner and adapt to an expeditionary setting.” The company has since been requested to quote for other expeditionary opportunities as a result, he notes.

To demonstrate cold spray for expeditionary manufacturing, HAMR Industries relocated its WarpSpee3D system to Virginia for REPTX. The team successfully reverse-engineered and manufactured a valve system in less than two days. Source: HAMR Industries

There is a pressing demand for such expeditionary manufacturing expertise, particularly for cold spray AM. Today there are 10 Spee3D systems located in Ukraine (seven provided via the U.S. and three via Australia) being applied to manufacture real parts at the point of need. HAMR Industries is assisting this effort from afar.

“Our team is currently working to establish a means to transfer knowledge and experience to the Ukrainian end users working to defend their country,” Schmitt says. Lessons learned in this environment can help to build a more robust domestic response, while also helping an ally.

Scaling to Production

The design flexibility that makes it possible for CSAM to reproduce a valve on location or reimagine a pressure vessel to reduce machining is central to the promise HAMR Industries sees in this technology. While producing replacement parts is a critical activity today for establishing AM pathways and winning the trust of organizations such as the U.S. Navy and Army as a supplier, new product development and production is one of the company’s long-term aims.

HAMR Industries cofounder Michael Schmitt sees a future for cold spray in scale production. Getting there demands intense understanding of the process alongside application development, challenges the company is committed to meeting.

“Spare parts is where we get to cheat by starting with what was there,” Schmitt says, “but we enjoy the challenge of bringing new things up the ladder.”

And the company is climbing that ladder. Some of the programs that HAMR is working on today are preparing to move into qualification activities, which could then lead to manufacturing in production. Right now, just one cold spray machine is enough to support HAMR’s work. But as programs develop, Schmitt envisions a future where its 3D printing activities scale significantly.

Among the projects in progress when I visited were parts for a major automaker. Like HAMR’s other clients, the company was looking for alternatives to castings for some metallic components of its vehicles. The work was in early stages, with many test coupons mixed in with the parts I saw on a workbench in the facility. But if an application like this were to take off, Schmitt says, “We could be building a HAMR factory.”

Related Content

America Makes Announces Winners for IMPACT Project Call

The project call focuses on additive manufacturing research related to casting and forging, metal powder sourcing and robotic AM process planning for continuous fiber-reinforced composite structures.

Read MoreSintavia Develops Niobium Printing Technology for Aerospace, Defense

C103 material parameter specification is said to enable full alloy adoption across defense and space applications.

Read MoreHow a DOD-Funded Resilient Manufacturing Ecosystem (RME) Is Coming Together at Neighborhood 91

Pittsburgh’s additive manufacturing campus doubles as a test bed for a Department of Defense project aimed at developing a reproducible ecosystem for on-demand production of critical parts.

Read More7 Takeaways From America Makes MMX 2023

America Makes just held its recent Members Meeting & Exchange. Here are observations related to cost and collaboration; digital manufacturing; and the sustainment and supply chain needs of the DoD.

Read MoreRead Next

Spee3D’s Metal 3D Printer First in World to Print Parts on US Naval Ship

Spee3D’s WarpSpee3D additive manufacturing technology was successfully used in the U.S. Navy’s REPTX exercise, which serves to demonstrate and evaluate the viability and efficacy of products and services that could expand the Navy’s ability to perform expeditionary maintenance operations.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreWhat Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

Read More

.jpg;width=70;height=70;mode=crop)