Neighborhood 91 (N91) is a first-of-its-kind campus dedicated to additive manufacturing for production. First announced in 2019, the site aims to house tenants representing all aspects of the metal 3D printing workflow. See it in the video below shot in 2022, or read on.

What Is Neighborhood 91?

Neighborhood 91 is a first-of-its-kind campus dedicated to additive manufacturing (AM) for production. The development seeks to bring all the pieces of the AM workflow together in one location, from powder and gas suppliers to 3D printing users to postprocessing suppliers. The site offers shared perks for tenants including bulk powder storage, a dedicated power grid, and the chance to share resources and knowledge amongst “neighbors.”

The first building of the Neighborhood 91 campus houses (left to right) Cumberland Additive, HAMR Industries, Metal Powder Works and Wabtec.

Where Is Neighborhood 91?

Neighborhood 91 is located adjacent to the Pittsburgh International Airport in western Pennsylvania. The site gives tenants easy access to shipping by air, land or water.

What Tenants Are Located at Neighborhood 91?

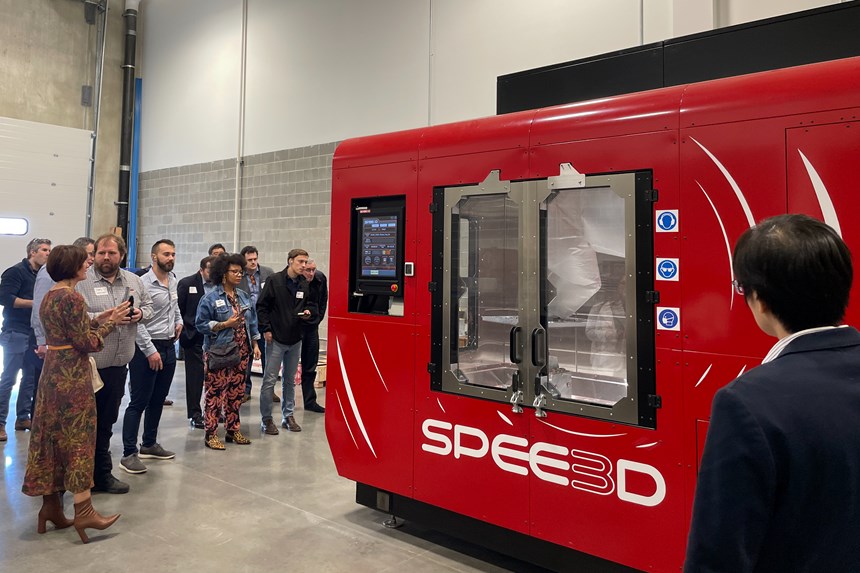

The first company to move in was locomotive manufacturer Wabtec, choosing to locate its laser powder bed fusion (LPBF) operations at the site. Contract manufacturer Cumberland Additive joined soon after, bringing its “lightweight metals”-focused LPBF production to the location. Cold spray specialist HAMR Industries and materials producer Metal Powder Works held a joint celebration for respective ribbon cuttings in 2023.

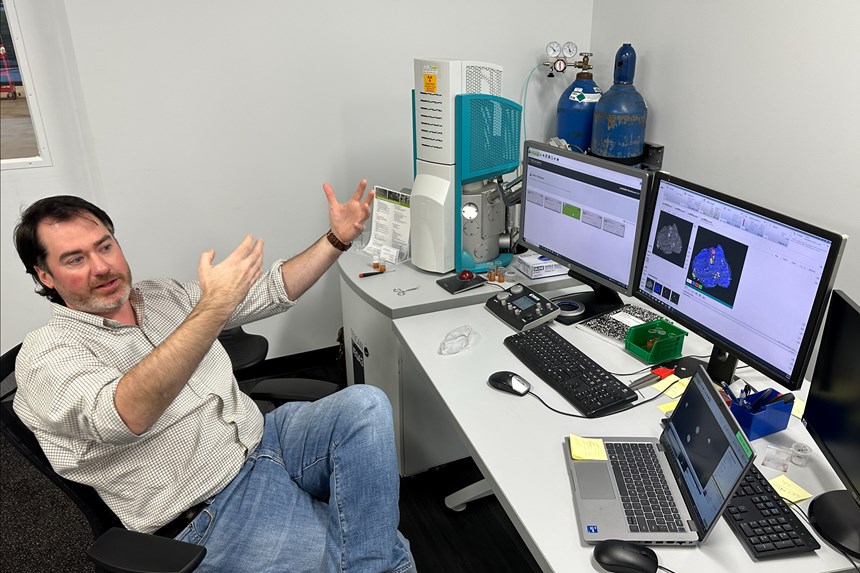

These four tenants occupy all the space in the campus’s first building, but additional businesses have found homes here as well. Also in 2023, JEOL established a presence at the campus with the installation of its electron beam melting (EBM) platform at Cumberland Additive, the first in North America. By 2024, two additional businesses joined the location as subtenants within the Metal Powder Works facility: custom signet ring company The Future of Jewelry (TFOJ) and testing and analysis company RJ Lee Group.

Tenants of Neighborhood 91

Ground has been broken on the construction of the campus’s second building, which will take lessons from the first, such as the addition of more shared resources including meeting space and amenities.

What Are the Benefits of Locating at Neighborhood 91?

Neighborhood 91 was established to be a largely self-sufficient manufacturing campus accessible by multiple means of transportation. Tenants benefit from shared resources such as a common powder storage facility, inert gas supply, an independent power grid, and in some cases manufacturing equipment. The campus is located adjacent to the Pittsburgh International Airport, as well as major highways, waterways and railways.

N91 tenants have also reported the sharing of services and additive expertise to be an advantage of colocating with the other businesses at this campus. For example, Metal Powder Works frequently supplies metal powders to next-door neighbor HAMR Industries; Cumberland Additive has performed finish machining operations for other neighbors; and all tenants have the advantage of the concentration of knowledge that now exists in this location.

What Are the Goals of Neighborhood 91?

Neighborhood 91 was established to be the “world’s first end-to-end additive manufacturing production campus.” Its stated mission is “To propel the New Collar Workforce through fostering a community of innovators in Pittsburgh — a global hub for engineering, manufacturing and technology.”

In addition to promoting a campus environment around additive manufacturing, the effort is also uniquely equipped to be a testing ground for other initiatives, such as the Resilient Manufacturing Ecosystem (RME).

What Does the Name “Neighborhood 91” Mean?

The city of Pittsburgh is said to have 90 distinct neighborhoods. The additive manufacturing campus is reportedly the 91st.

Who Started Neighborhood 91?

Neighborhood 91 was developed by key partners The Barnes Global Advisors (TBGA), the University of Pittsburgh and the Pittsburgh International Airport. The project was announced in 2019.

See Neighborhood 91

We visited N91 in 2022 to meet with its first tenant, locomotive manufacturer Wabtec. See what the site looked like at that time in the video below.

Related Resources

- The initial announcement of this end-to-end ecosystem

- A look inside the N91 facility of Wabtec, the neighborhood’s very first tenant

- A 3D printed brake panel made at this facility featured on The Cool Parts Show

Transcript

Peter Zelinski

We’re at Neighborhood 91 in Pittsburgh, Pennsylvania. Industrial Park devoted to additive manufacturing. We're here to give you a look at how Neighborhood 91 is taking shape.

Stephanie Hendrixson

The concept for this site is to bring together all the different parts of the additive manufacturing supply chain together in one place. There will be parts producers here that will be able to share resources, everything from powder storage to a microgrid that all of these different businesses can operate off of.

Peter Zelinski

Construction is underway, as you can see, but some of the tenants are already moved in.

Stephanie Hendrixson

The very first tenant to move in was Wabtec and they are already 3D printing parts for the rail industry here at this site. Joining them soon will be Cumberland Additive. Both of those companies are parts providers, but we're also going to get different upstream and downstream suppliers later. So future tenants include Arencibia which is a company that produces and recycles argon gas. Also Rusal America, which produces metal powders for 3D printing. And then later on companies providing other services like heat treat, quality assurance and finishing that might be needed.

Peter Zelinski

For a look at some of the 3D printing metal part production that's already being done at Neighborhood 91, check out our episode of The Cool Parts Show about Wabtec and brake system components.

Stephanie Hendrixson

And for more information on Neighborhood 91, check out our website, AdditiveManufacturing.media, as well as Neighborhood91.com.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreVelo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

Additive Manufacturing for Rail Industry Is Gaining Traction at Neighborhood 91

Locomotive manufacturer Wabtec is the first tenant of Pittsburgh’s N91 additive manufacturing ecosystem, where the company is ramping up production via laser powder bed fusion.

Read MoreNeighborhood 91 Expands, With Metal Powder Works and HAMR Now Open

Ribbon cuttings for the Pittsburgh campus's newest tenants coincided with the announcement that a DOD-funded resilient manufacturing program will also be developed at the site.

Read More3D Printed Brake Panel for the Rail Industry: The Cool Parts Show #52

In this episode of The Cool Parts Show, laser powder bed fusion simplifies the manufacturing of air brake panels for light rail systems made by Wabtec.

Read More

.jpg;width=70;height=70;mode=crop)