Slideshow: Inside the New Honeywell AM Facility for Reactive Metals

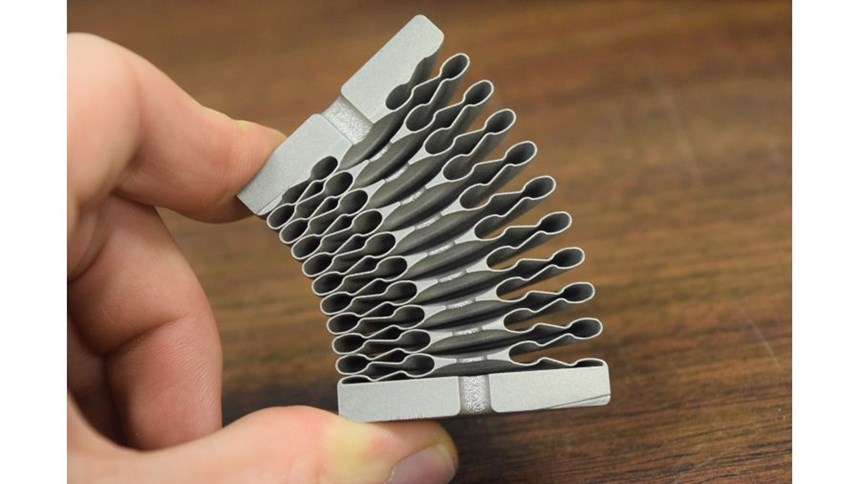

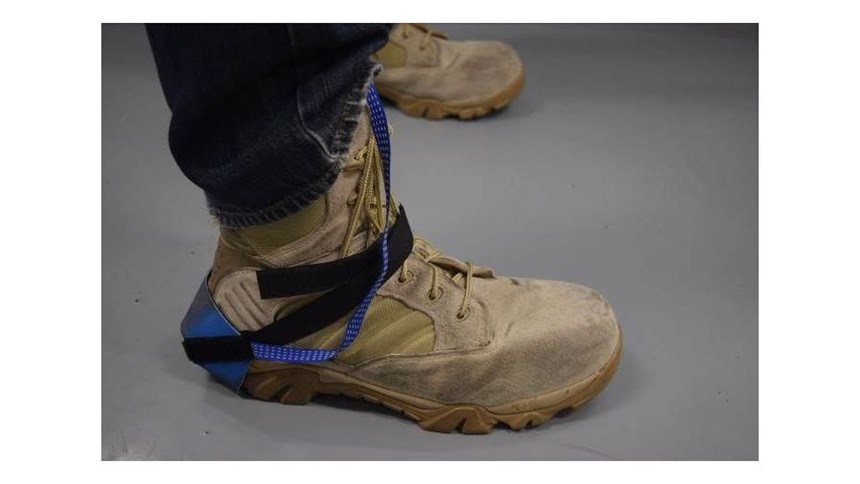

Seven machines currently committed to aluminum expand the company’s capacity to 3D print both tooling and parts. One of the photos illustrates a safety measure addressing reactive metals.

As reported in this article in the Phoenix Business Journal, Honeywell Aerospace has opened a new facility as part of its Phoenix Additive Manufacturing Technology Center that is devoted to reactive metals. At present, the new facility’s capacity is committed to aluminum, but it was recently approved for titanium-aluminum alloys as well.

Honeywell says this is the first AM facility in North America with this focus. Company engineering fellow Donald Godfrey leads the site. He expects the seven metal additive machines here will pay for themselves through the savings and speed resulting from the company’s now-increased capacity to grow aluminum parts and tooling in-house.

The article also reports that further investment in AM is coming. Honeywell plans a 30,000-square-foot facility for production additive manufacturing that will have another 10 to 16 machines.

Use the “Next Image” button above to view images from inside the new facility.

Related Content

-

AM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

-

AM 101: NanoParticle Jetting (NPJ)

The proprietary process from XJet builds ceramic and metal parts using nanoparticle suspensions. Learn how NPJ works in this introductory article, part of our AM 101 series.

.jpg;width=70;height=70;mode=crop)