Sand 3D Printing Benefits Lightweighting and EV Production

Brooks Crownhill Limited has used Voxeljet’s sand 3D printers to rapidly prototype automobile part molds, with the increased design flexibility enabling lightweighting while strengthening individual components.

The VX1000 from Voxeljet can use either furanic or phenolic resin to maximize the flexibility and choice of sand materials for metal casting. It has a build area of 1000 x 600 x 500 mm.

Photo Credit: Voxeljet

Brooks Crownhill Limited (BCP) uses Voxeljet’s 3D sand printing systems for prototyping a variety of automotive parts. This strategy enables the company to rapidly design and test highly-complex parts before manufacturing production tools, saving time and money.

Sand molds are relatively cost-effective and sufficiently refractory for application in steel and aluminum foundries. For this reason, casting with sand molds continues to enjoy great popularity, especially in the automotive industry. Voxeljet says industrial 3D printing technologies like its own binder jetting system have expanded foundaries’ range of design possibilities to include highly complex molds and cores.

Light, Enhanced Designs

"We have been using 3D printing and casting, or printed casting, for quite some time now,” says Lee Henderson, sales director at BCP. “The process is fast, cost-effective and gives designers enormous creative freedom. This is important for rethinking established components and saving as much material as possible, for example by optimizing the topology of the components."

“Today, engineers can use finite element analysis (FEM) to optimize functionality and then directly 3D print the designs,” Henderson continues. “This makes the design of engine parts a lot faster and, more importantly, the components are stronger, which in turn allows drastic weight reductions. This is extremely attractive, especially in the wake of current environmental regulations such as lightweight construction, and the associated energy savings."

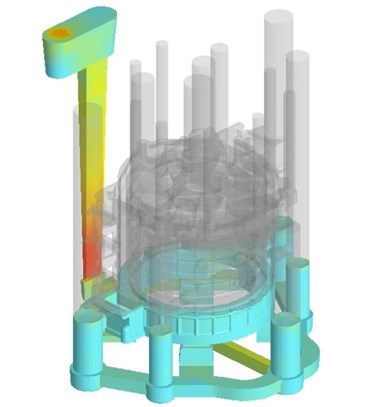

Through redesigns for 3D printing, BCP optimized this core for electric engine housing to enable more efficient engine cooling. The core is made of special ceramic sands that ensure stability and precise tolerances during metal casting.

Photo Credit: Voxeljet

Voxeljet says “lightweight” design is one of the most important design trends of recent years. Customer designs move closer and closer to the limits of manufacturability with thinner wall sections of the entire casting and higher tolerance bands for positional accuracy. As BCP largely manufactures engine components and, more recently, electric motor housing components for its customers in the automotive sector, it is on the forefront of this design trend.

"3D sand printing is irreplaceable,” Henderson says. “Not only because it allows us to realize geometries that would not be possible using conventional processes such as milling or core shooting, but, especially when we want to test brand new designs, we need the optimized prototypes quickly. We then take a close look at these with specific integrity tests (NDT, non-destructive testing) before we give the go-ahead for series production."

New Metal Casting Possibilities

"In modern engineering, 3D printing means above all that we can print complex inner cores as one part,” Henderson says. “This saves us a lot of work in casting preparation. And we can be confident that all tolerances on wall thickness and the associated stability of the cores will be maintained during the enormous stresses of metal casting. Further economic opportunities are opened up by time-saving printed castings when you reduce potential costs and conventional assembly time on complex core-stack assemblies line-side. This has a direct impact on the business model, ongoing costs and delivery times to the customer."

However, Henderson also notes that the benefits of additive manufacturing of molds and cores are not yet one hundred percent clear in the minds of engineers. "3D printing, unfortunately, still has a niche existence,” he says. “It is increasingly recognized within the foundry industry as a fully-fledged manufacturing process for casting molds, but I'm not sure to what extent the advantages are even known by both engineers and also the key buyers. There are still unimagined design and cost opportunities that could be leveraged here."

With casting simulation, users can test the behavior of molds and cores before the actual casting. If the simulations reveal any potential threats, users can then digitally optimize the molds and cores before printing to ensure an ideal casting process.

Photo Credit: Voxeljet

Process Optimization through AM Design

Other advantages go beyond the product, into the production process itself.

"With 3D printing, we can plan gas channels into the sand cores and molds during the design stage,” Henderson explains. “These are used for venting and outgassing during the casting process, making our job much easier, and have a great effect on the quality of the cast parts in terms of density and surface quality. Adding structural tie rods for better transportability of the parts is also possible and simplifies the handling of the printed parts."

BCP also relies on the use of different sand systems for specific applications. For example, it uses high-strength and high-temperature cores to ensure stability and concentricity of the inner cores during the casting process of high-temperature alloys.

Related Content

Robot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreAM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MoreRead Next

Casting Goes Digital with Sand 3D Printing, Nondestructive Testing

Tooling & Equipment International (TEI) used to make tooling for castings. Now, it casts prototype parts in a digital workflow using 3D printed sand molds in combination with simulation software, CT scanning and X-ray technology.

Read MoreAdditive Manufacturing Creates New Paths to Production

On the journey from product idea to production, when does the “mold moment” come? That is, the moment of needing to invest in tooling and make design commitments. 3D printing can delay this step on the journey or even avoid it altogether.

Read MoreAdditive Manufacturing and Metal Casting

How is additive manufacturing disrupting metal casting? A hybrid approach to consider.

Read More