Learning by Doing

The production of our own AM part gave us a direct experience of additive manufacturing. One of the insights: Uncertainty is part of the process for any new part made this way.

Share

An additive manufacturing machine is not a printer. It’s not even close. The term “3D printing” carries an unfortunate implication, particularly with regard to metal parts, because this term suggests that the machine generates a solid part from the CAD geometry as seamlessly and reliably as a printer generates a physical document from a Word file. This is not the case, and as additive manufacturing advances, its prospective users are increasingly becoming aware of this.

However, an additive manufacturing machine also is not a machine tool. This is the point that still deserves to be better understood. Even after additive manufacturing has matured into an established, widely used production process, the machines that apply this process still might never become the additive equivalents of subtractive machines. Additive manufacturing might always require a distinctive way of thinking about the manufactured part, as well as distinctive ways of thinking about how the manufacturing process is applied. For the companies active in additive manufacturing today, part of the learning curve they are rising through involves discovering and embracing the ways that the rhythm and mindset of additive manufacturing are different from other, more established methods of production.

One of those companies is Linear Mold & Engineering. At its headquarters facility in Livonia, Michigan, this company has 18 powder-bed metal additive manufacturing machines in use, making it a leader in additive capacity alone. I recently worked with Linear on a special project: producing a 3D metal version of our “Additive Manufacturing” logo to commemorate the expansion and redesign of this magazine. It was an unusual job for the company, which is accustomed to using its additive equipment to make functional engineered parts such as aircraft components. The experience was also unusual for me. Whether I am writing about CNC machining for Modern Machine Shop or additive manufacturing for this magazine, it is rare that I witness a single part’s journey all the way through conception and production. Watching “my” additive part move through the process at Linear gave me a chance to directly witness the kind of thinking and effort that are characteristic of this process, and the sorts of considerations additive manufacturing demands that differ from any other method of making parts.

Linear’s president, John Tenbusch, routinely explains both to customers and to companies considering additive manufacturing that the machine alone accounts for at best just 30 percent of succeeding with additive.

So what goes into the other 70 percent? Perhaps I knew this much, but it was certainly confirmed to me: One of the considerations is a clear-eyed acceptance of the possibility of failure.

Ten Years of AM

Linear began as a machine shop. More specifically, it began as a tool and die shop. The company bought its first EOS powder-bed metal additive manufacturing machine in 2005 with the aim of using it to make mold inserts. Unlike machined inserts, mold inserts that are grown additively can include internal cooling channels that wend and spiral to follow the contours of the mold surface, achieving dramatically more effective cooling than straight channels that are merely drilled. Supplying these conformal-cooled inserts to moldmakers is a business that continues to grow for the company. However, making prototype and production parts through additive manufacturing for sectors including aerospace and defense is a business that has grown faster, so Linear has expanded and changed over the years to become something more than solely a toolmaker.

Today, Linear believes it has more metal additive manufacturing machines in use than any other independent manufacturer in North America. Machines at the Livonia site come from EOS and SLM Solutions. Of the company’s 140 employees, 40 officially belong to the additive manufacturing group, while approximately another 30 are so involved with additive manufacturing that it accounts for the majority of their time. For example, 95 percent of the wire EDM team’s work consists of completing additive jobs by wire-cutting finished parts off of build plates. This year (2015), Linear’s additive manufacturing sales are likely to overtake its sales in traditional moldmaking and machining, despite the fact that its activity in these areas has also been steadily growing.

A walk through the company’s facility gives lie to the widespread misconception that additive processes are only for prototyping and don’t have a role in production. Additive build plates throughout Linear’s shop are full of batches of identical parts. The work is almost all confidential, so no photographs of the parts appear here and I won’t describe them, but it was production parts I saw queuing at the wire EDM.

To be sure, just a few customers have gone so far as to commission Linear for ongoing, volume additive production of an established part number. Their production work occupies six of the additive machines. Yet these customers are just slightly farther ahead than others, say company leaders. Several other customers are far enough along in their development efforts for additive parts that they are close to committing to additive production themselves. Thus, Linear is contemplating an expansion of its headquarters that will add enough room for more metal additive machines.

Design Choices

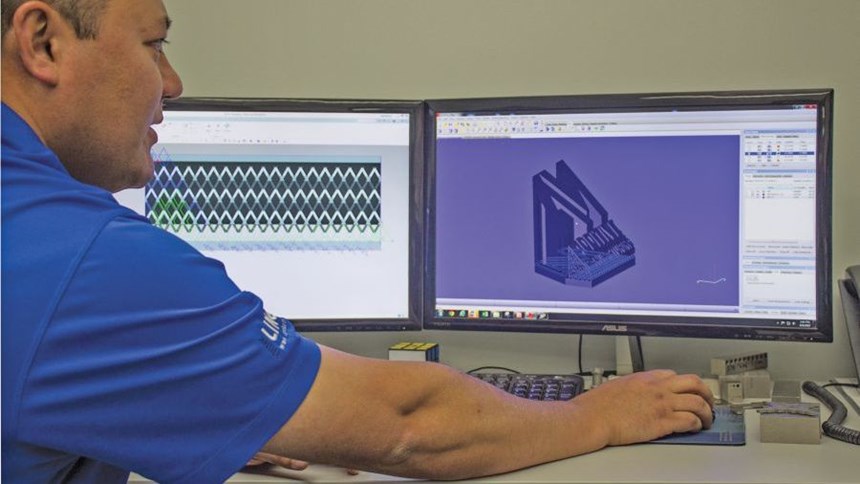

CAD Operations Manager Kevin Jonatzke is the one who turned the 2D logo and title of the magazine into a 3D part. I initially thought he might see this weird assignment as having drawn the short straw, but he persuaded me later that he had fun getting to take this on.

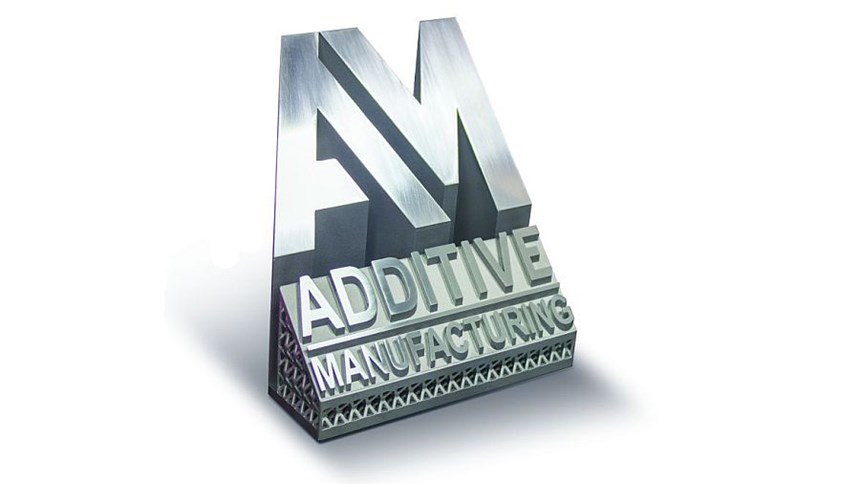

My agenda was to obtain a monolithic part that could only be made through additive manufacturing. That, after all, is additive manufacturing’s chief promise: It will enable surprising part designs that are not being considered today because they are not possible to produce using established processes. Jonatzke delivered on that aim, creating a form featuring a lattice structure, deep pockets with sharp internal corners and hollow recesses inside of the supports that hold up the “AM” logo form. As a practical matter, no mold or machine tool could have produced this part in one piece.

I discovered later that Jonatzke had an agenda of his own in the design choices he made. Specifically, he wanted to maximize the likelihood that the build would be successful. At 6 × 6 × 6 inches, the part I was asking for was on the large side relative to other parts produced on powder-bed machines. The resulting cycle time for this part within the machine would be 32 hours, and I was asking Linear to make two of them. Plus, I confess that we didn’t come up with the idea to have a part made for our first new issue until rather late in our own process, so there was a leadtime constraint. Accordingly, Jonatzke made conservative choices in the part’s design to minimize the risk that the build might fail, and thus consume valuable time.

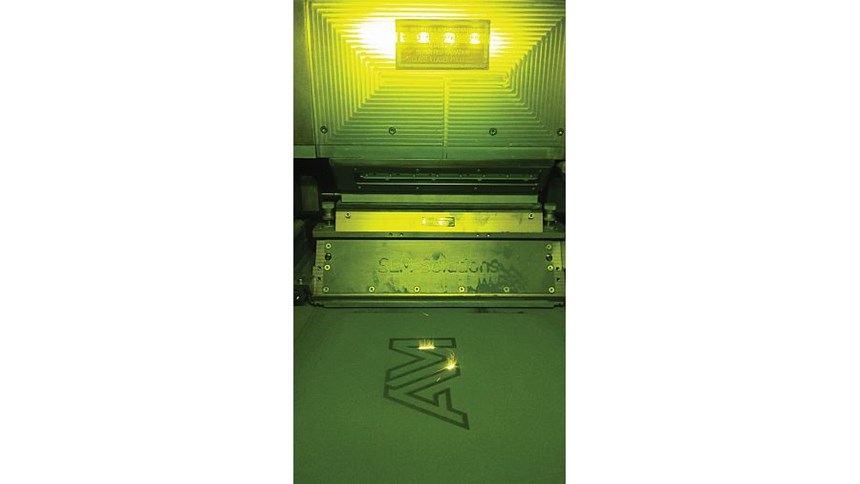

For example, any overhanging feature with an angle of up to 45 degrees from vertical usually can grow successfully on its own without the need for supports underneath. However, to be safe, Jonatzke designed the lattice features in the logo part to depart from vertical by just 30 degrees. In addition, while he could have made a lighter part using less metal by devising a system of thinner walls to support the logo, he opted for a wall thickness of 1.5 mm because experience has taught Linear that this wall thickness works reliably for tall walls in aluminum. The aluminum alloy, AlSi10Mg, was chosen because of this material’s low tendency to distort from thermal stress. That choice incidentally suggested which machine would be used, because Linear’s machine number “SLM3” (from SLM Solutions) is kept dedicated to running this aluminum alloy.

Different from Machining

Recognizing the potential for a build failure is inherent to additive manufacturing (at least as it exists today), and the nature of that potential makes additive very different from creating a part through machining. A machining cycle even for a new part is generally predictable enough that, if the part is scrapped, the reason usually is something having gone wrong. That is, there was a tool break or some other fault. But in additive manufacturing, a build fails because the designer and manufacturer have not yet learned what is right when it comes to that particular part. For any additive job, generally the part geometry combined with the complexity of the behavior of the material produces a large realm of uncertainty, meaning a large range of part-geometry and parameter choices that simply might or might not work. Typically, the only way to find out is to try. With the logo part, the geometric requirements were so few that this part could be designed to play it safe, maximizing the likelihood the build would succeed. By comparison, while this part was being built, Linear tried to economize the cycle by building a customer’s unusual heat exchanger component on the same plate at the same time. That build failed—its geometry collapsed—leaving the rest of the cycle devoted to the logo part alone. Linear’s experience over time has steadily increased the team’s effectiveness at anticipating and preventing build failures. But even so, in additive manufacturing, the company’s most successful customer relationships have involved companies willing to explore with Linear what works and what does not—that is, willing to invest in potential failure—in order to find the best design and parameter choices for a given job.

Here are some other ways additive manufacturing fundamentally differs from more traditional part-making methods, machining in particular:

- Long cycle times. Certainly machining can also have long cycle times. However, in additive manufacturing of metal parts, cycles extending to 24 hours or more are the norm. The machines’ controls feature a continually updated prediction of the remaining build time for the job, similar to the prediction of time remaining when a large file is being copied to your computer. Employees in the additive area keep an eye on these time estimates to anticipate which machine will be ready next for unloading and changeover to the next job.

- Rough finish. In machining, the surface finish of the final part is far more controllable. Light cuts with a carefully chosen cutting tool can achieve a finish that is smooth. But in additive manufacturing, the lack of any similar control over finish means that AM—as labor-free as it is during the build cycle—is often followed by extensive hand finishing as the very next step. Indeed, this is an important point about additive manufacturing that is not sufficiently appreciated. Linear has a hand-finishing area devoted to additive manufacturing that is generally staffed by 12 people at a time.

- Microstructure management. In machining, the part’s microstructure is in place before machining begins. Certainly it can change at the surface through work hardening. But in additive, all of the metallurgical structure of the part comes together during the cycle. It also changes as the cycle proceeds. The result is a far more dynamic and less predictable process than machining. In particular, the possibility for residual stress to distort the part as it grows has to be anticipated in additive. Lattice structures like the ones in the logo part are risky, Jonatzke says. In a material more prone to stress distortion (such as titanium), a distortion causing an incomplete lattice to rise vertically by a microscopic amount could turn that feature into a hook to seize or scar the recoater bar that is distributing powder during the build. Watching how residual stress will play out in the build of a particular form is one of the reasons for the trial and error that additive requires.

Linear has also found one further way that additive manufacturing is distinct. In additive, the company has concluded that the techniques it has learned are better shared, so it freely teaches them. It does this through training given even to companies considering their own additive machines. In an organized, detailed, week-long instruction program, Linear employees regularly teach small classes of visitors about the company’s approach to CAD file preparation for additive, machine setup, part design considerations, EDM technique for finished builds and methods for maintaining part traceability in the AM process. Linear considers it a benefit to the company to see this knowledge advance. More knowledgeable customers will be able to make better use of the potential that additive manufacturing offers them. And companies that go so far as to install their own machine will find so much use for additive that Linear expects one machine alone will not fill the demand, leaving Linear (it hopes) as an obvious choice for the overflow.

Stay Tuned

The big question is whether additive manufacturing will always be so different. In the future, additive manufacturing build speeds will be faster, adoption will have spread and the metallurgy of part formation will be better understood. As these successes accrue, will there come a time when an additive manufacturing machine essentially is a machine tool—producing parts as predictably as a lathe or machining center does?

Or is it more true to say uncertainty will always be part of this process?

I don’t know the answer. I suspect today’s users of additive manufacturing can’t predict the answer, either. But stay with us—keep reading this magazine—and let’s see whether the answers to questions such as this one become apparent over time.

Related Content

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More