KraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, the 184-yr-old company will enter the industrial additive manufacturing market.

This article was originally published by our sister publication, Plastics Technology (PT).

Previewed in June at a pre-show event and teased once more in a noontime press conference on the first day of K 2022, the trade show for plastics and rubber held in Germany, plastics processing machinery company KraussMaffei (KM) used a dramatic curtain dropping at its show booth to literally unveil two new additive manufacturing platforms — powerPrint large-format and precisionPrint small-format machines.

In the press conference, Michael Helneder, who leads the new division at the long-storied company, said the company’s goal is to further industrialize additive manufacturing (AM). “Our mission is to provide additive manufacturing solutions that are matched to applications, machines and materials correctly the first time,” Helneder says, noting that an end-to-end process that avoids potentially expensive and time-consuming optimization would be a requirement for the reliable industrialization of additive manufacturing.

KraussMaffei’s precisionPrint features a resolution of 18-80 µm with a build volume of 250-by-250-by-400 mm (10-by-10-by-16 in). Photo Credit: KraussMaffei

The precisionPrint is UV laser-based AM process, promising high dynamic resolution of 18-80 µm with a build volume of 250-by-250-by-400 mm (10-by-10-by-16 in). The machine is built around a dual-tank system, automated build plate changer and a long-life, 405-Nm industrial laser. The company said the tank system enables separation of parts building and handling.

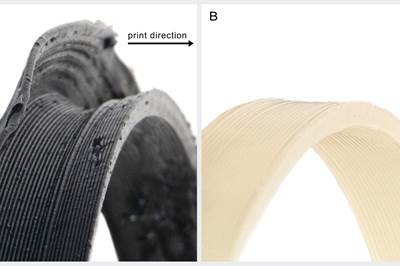

While the precisionPrint display was static, the larger powerPrint system was running at the show, with samples of parts it has created for the foundry industry also on display. Described as an extruder-based gantry system, powerPrint runs standard resin pellets in a process called Fused Granulate Modeling (FGM) for components as large as 10 m3. The machine has a build volume of 2,000 by 2,500 by 2,000 mm (79 by 98 by 79 in).

For components as large as 10 m3, KM’s powerPrint has a build volume of 2000 by 2500 by 2000 mm (79 by 98 by 79 in). Photo Credit: KraussMaffei

There are two sizes available with output capacities up to 10 or 30 kg/hr. Customers can specify the screw design, with extruder temperatures up to 400°C for processing thermoplastics composites and high-temperature resins, with nozzle sizes ranging from 2 to 20 mm. The heated vacuum print table has 16 zones, with the entire system surrounded by a heat-resistant enclosure.

Material drying is connected with the material supply by a vacuum supply system, which KM says enables continuous production without operator intervention. Depending on requirements, multiple mounting surfaces can be configured with a preset printing table temperature. The maximum printing bed temperature is 140°C. The Printcore extruder printer head is guided by linear robots from KraussMaffei, with a maximum travel speed of 300 mm/sec.

The user interface is based on HTML5 working in standard slicer output files, which KM says makes data preparation and print file creation easier, with data transfer from the preprocess system able to be done wirelessly or via USB. The company stated in a press release it will enter an intensive test phase with beta customers in 2023, after which the printers will be commercially available.

Related Content

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreSolving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreRead Next

Metal Parts Are Now Within Reach for Users of Polymer 3D Printers

An option for accessible metal 3D printing: New metal composite filament from BASF Forward AM has made it easy for Austrian company Sparox 3D to pivot its Ultimaker FFF capacity into metals, without major additional investments in skills or equipment.

Read MorePLA for Large-Format Additive Manufacturing

NatureWorks’ new Ingeo 3D700 shown to provide significant reduction in warping, minimizing print failures.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More