Polymer 3D printing brings accessible geometric complexity, but a plastic part might not deliver all the functionality the application demands. For situations requiring electrical conductivity, EMI shielding, heat conductivity or greater strength than polymer alone, electroplating these parts can be an option. RePliForm in Baltimore, Maryland, specializes in plating polymer printed parts with layers of nickel and copper to achieve the desired effects. This video provides an overview of how the process works (from part design through plating) along with considerations for taking advantage of electroplating as an option between straight polymer and directly 3D printed metals.

Related Resources

- Much more on RePliForm and applications for plated polymer

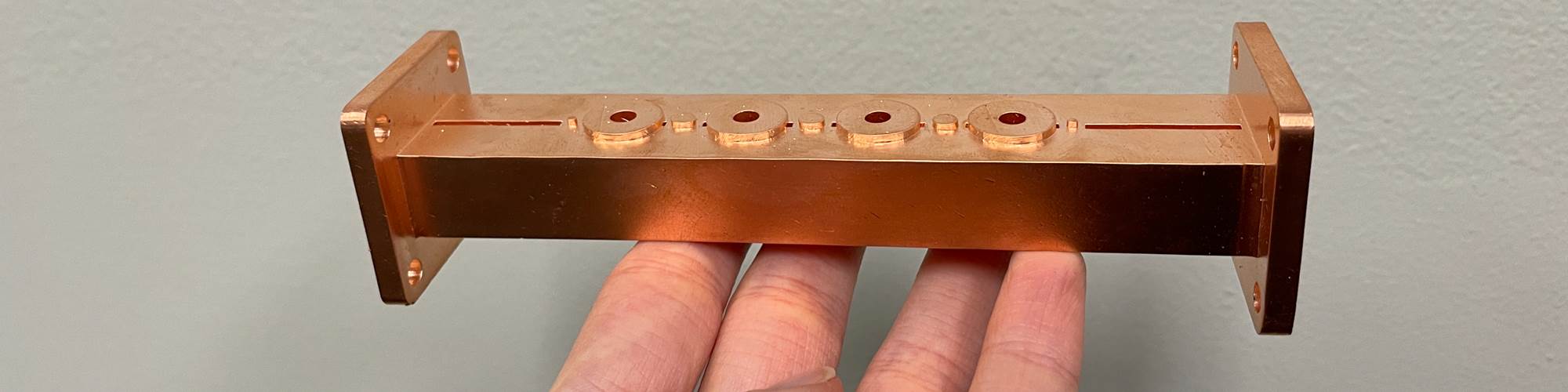

- An example of a copper plated polymer antenna in The Cool Parts Show RAPID 2022 episode

- A conversation on finishing’s role in additive manufacturing

- More on electroplating from our sister publication Products Finishing

Electroplating FAQ

What do I need to consider when electroplating 3D printed parts?

- The parts must be designed for electroplating. For example, the parts may need offsets to accommodate the added finishing material.

- The parts must be watertight as the process requires full immersion into liquid solutions.

- The parts must be clean. Oils and loose particles can hinder the electroplating process. Read: Preparation for Electroplating

What is RePliForm’s process for electroplating polymer 3D printed parts?

- The parts go through a mechanical etching process.

- The parts are metallicized in a room temperature electroless nickel process.

- Once conductive, the parts are electroplated with copper, nickel or a combination of the two.

Why electroplate polymer 3D printed parts?

Electroplating polymer 3D printed parts can provide similar properties of a metal part — without committing to a fully metal 3D printed part. These properties include

- Aesthetics

- EMI shielding

- Electrical conductivity

- Heat conductivity

- Improved strength

Transcript

What do you do when a straight 3D printed polymer part isn't quite good enough, but going all the way to direct printed metal isn't an option?

Well electroplated 3D printed plastic might be an option.

I'm Stephanie Hendrixson with Additive Manufacturing Media. I'm here at Repliform in Baltimore, Maryland, where they specialize in electroplating of 3D printed polymer parts. Parts need to be designed for this process, so they probably need offsets to accommodate for the material that's going to get added during the printing process. They have to be watertight, and they also need to be very clean.

When parts come into Repliform, they first go through a mechanical etching process, and then a room temperature electroless nickel process to be metallicized to be prepared for the electroplating process that allows them to be conductive so that they can be electroplated with copper, nickel, or some combination of those different materials to impart the desired characteristics.

There are a lot of different reasons that you might want to electroplate your 3D printed parts, including aesthetics, but also things like EMI shielding, electrical conductivity, heat conduction, as well as mechanical properties. You can improve the strength of the polymer part through this process, giving you an option in between 3D printing with straight polymer and going all the way to direct metal 3D printing.

Related Content

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreRead Next

A Conversation on Finishing's Role in Additive Manufacturing: AM Radio #12

Conventional finishing techniques like electroplating and powder coating have a role to play in AM. Stephanie Hendrixson and Scott Francis discuss how additive will go farther with finishing on the latest episode of AM Radio.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read More

.jpg;width=70;height=70;mode=crop)