3D printing offers the ability to get a product off the ground quickly, without tooling and at lower cost than conventional manufacturing technologies. But if the 3D-printed product has only a temporary lifespan, there is a danger that this shortened supply chain is only speeding its journey to the landfill.

For Pengraff UK, a small business located in the United Kingdom, 3D printing has been an enabling technology for all the benefits listed above. Matthew and Rebekah Farmer initially purchased an Ultimaker 2+ in 2016 for their own hobby use. Since starting their business in 2017, they have now sold more than 20,000 3D printed products to customers in the UK and continental Europe. The couple were able to launch their business manufacturing mounting solutions for consumer electronics and providing prototypes along with design and print services, thanks to the cost savings and flexibility of 3D printing compared to conventional manufacturing methods.

Sustainability has always been a core value of the business. The plastic mounting solutions that Pengraff UK produces are durable and strong, but not intended to be used forever. Consumers will upgrade their routers, and manufacturers will change the designs of this hardware. So what does a sustainable business look like when the nature of its product is temporary? In Pengraff UK’s case, it is a balance of on-demand manufacturing enabled by 3D printing, insourcing all parts of the design and manufacturing process, and responsibly sourced materials.

Solving One Problem Reveals More

Rebekah’s background is in the recycling industry and international trading along with design and business management; meanwhile Matthew is a veteran U.S. Air Force aerospace propulsion craftsman with mechanical engineering and design expertise. The impetus to launch the Pengraff UK business came from a problem that the Farmers were experiencing shortly after deciding to purchase an Ultimaker 2+ 3D printer for their own personal use.

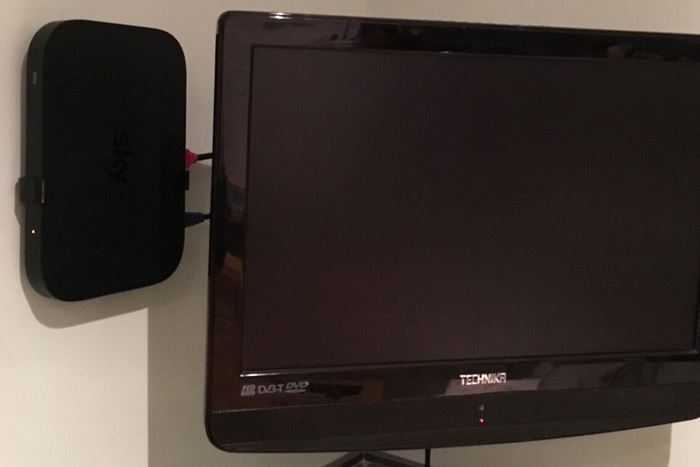

“We had a BT Home Hub, and it was just sitting on a bookcase in our hallway taking up a lot of space,” Rebekah says. “We looked online to see if we could find a wall mounting solution to get it out of the way, but there wasn’t anything on the market. Then we said, why don’t we see if we could make something ourselves? And that’s what we did.”

The couple tested some different designs and eventually came up with one that worked to mount the hub to the wall. “We wondered if other people might have a need for the same product, so we just floated the idea on eBay,” Rebekah says. “Really quickly we got a lot of people buying the mounting solution we’d made but we also had people contacting us about other products. We started taking bespoke requests, and now we have a line of products that were the first to market when nothing else was available.”

That initial exploration led the Farmers to launch Pengraff UK in October 2017. Today about 50 percent of its business is dedicated to manufacturing mounting solutions, while the rest is made up of prototypes and design and print services. Mounting solutions from Pengraff UK include products for the Sky Q Mini, Sky Q Booster, Sky Q Hub, Sky SR101/102, EE Smart Hub, BT Home Hubs, BT Smart Hub 2, NOW TV Hub Two, Plusnet and traveling watch mount for the Suunto Ambit.

3D Printing Enables Insourcing

Since October 2017, production capacity has expanded to include three Ultimaker 2+ 3D printers that operate 24/7 at their site in Cambridgeshire. Pengraff UK has stayed with this printer model even as the business has grown because of its dependability; access to support and user networks; and overall simplicity but with the option to upgrade or use more advanced features if the user chooses. Pengraff UK has found its printers to be fast enough for production needs and reliable enough to support near-constant operation.

“For our business these printers have been great,” Matthew says. “We literally hit print and forget about it. Ninety-five percent of the time they come out perfect, and the other 5 percent is human error. Obviously good maintenance is key to these machines; just like a car, they do need love sometimes.”

3D printing is what made the Farmers’ business viable in the first place, allowing them to go into production without the expense of tooling that would be necessary to injection mold these plastic products. There are no plans to pursue other forms of production at present. 3D printing is cost-effective and fast enough to meet their needs, and the ability to manufacture on demand means that there is no need to make and store large inventory. But 3D printing also provides an added benefit: insourcing.

At Pengraff UK, insourcing means product development as well as manufacturing. The company performs all its own design and rigorous product testing for new items. When designing a mounting solution for a new product model, the company will source that model for development testing to ensure that its product will fit and support the hardware as expected.

“We have direct oversight over what we’re supplying.”

For bespoke products, the Farmers work directly with their customers. “We have direct oversight over what we’re supplying,” Rebekah says. “If the customer isn’t happy or they have a query about a product, they know they’re actually speaking to the people who design and make the products. We’ve seen a lot of repeat business because of that. Pengraff UK has become a brand people know and trust.”

Insourcing also has a sustainability element to it, Rebekah says, allowing the company to have a smaller carbon footprint. Injection molding carried out by overseas manufacturers would be a possible alternative, but it comes at the price of tooling, shipping costs and import fees. For the quantities Pengraff UK needs, this approach would be cost-prohibitive. Keeping production on 3D printers in house allows for greater control over the process, more flexibility for new and custom parts, and on-demand manufacturing to help reduce waste.

Injection molding overseas comes at the price of tooling, shipping costs and import fees. #3Dprinting is this company's solution - via @addmfgmedia https://ctt.ac/Qke0T+

Second Life for Plastics

Manufacturing locally and on-demand can only go so far toward sustainability if the impact of the product being manufactured offsets these positives, however. “When I worked in international recycling, I dealt with the plastics, cardboard and paper industry,” Rebekah says. “I know that a lot of plastic goes to landfill, and products that people get rid of can’t be recycled because of the type of plastics or mix of materials used.”

The Farmers recognize that the mounting solutions they manufacture are not products that will be used indefinitely, so it was important that they find a way to manufacture with recyclable plastics. Fortunately, early on they encountered another UK-based startup with business ideals that aligned with their own.

That startup, Filamentive, supplies 3D printing filaments made from recycled material. The company uses both post-consumer recyclables from household and industrial use, as well as pre-consumer recycled plastics diverted from the waste stream during manufacturing processes. The polymer materials they produce are strong and durable, comparable to conventional plastics, but have the added benefit of breaking down more quickly once discarded. Pengraff UK prints using a variety of plastics as needed for specific applications.

To support the growing business, Pengraff UK expanded from selling on eBay to distribution through a reseller as well as its own online store. The Farmers are also looking at adding a fourth printer soon, possibly one with a larger build plate that would allow for printing larger parts or perhaps more pieces in a single build to support the prototyping arm of the business.

“We enjoy the challenge that each new business brings with their requirements.”

The company is also seeking other opportunities for consumer products and in other industries such as aviation. (The latter is of particular interest because of Matthew’s military background; a 3D-printed part he designed is already being used in aircraft maintenance for the U.S. Air Force.) The company has also provided parts to teams competing in British Superbikes, and this year is sponsoring and suppling parts to True Heroes Racing, a motorcycle race team that supports injured service people.

Many of Pengraff UK’s customers have stories similar to their own. “They will say to us: I’ve got this idea. Can I send you a file?” Rebekah says. “We can work with them to help get their product perfect. They then have the decision of whether they want to go down the route of outsourcing, employing us to produce products for them or moving on to form their own business like us. We already work with larger, established companies to provide working parts for equipment installations and products. We enjoy the challenge that each new business brings with their requirements.”

Related Content

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Additive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read MoreNiche Manufacturer Discovers How Additive and Amazon Go Together

The economics of 3D printing allow for cost-effective production of niche products, and Amazon Prime offers a way to distribute them. The Periscope Case is one company’s first venture into an all-new model aimed at bringing products to market that would never have been profitable before.

Read MoreLarge-Scale 3D Printing Supports Innovation in Construction

Branch Technology’s robot-based Cellular Fabrication (C-Fab) 3D printing technology builds open matrices in high-performance polymers. These structures could be the framework for better, more sustainable building practices.

Read More

.jpg;width=70;height=70;mode=crop)