Getting to Production Faster with 3D-Printed Press Brake Tooling

A case study from Centerline Engineered Solutions demonstrates that a 3D-printed die and punch can withstand press brake forces, providing a cheaper, faster path to production.

Metalforming with a press brake involves placing sheet metal between a punch and die and applying force to bend the sheet into a desired shape. While standard metal punches and dies are available for common features such as 90-degree angles, many parts require some type of specialized tooling. Typically such tools are machined from metal, in a costly process that can take days of a machinist’s time and delay part delivery.

A case study from Centerline Engineered Solutions illustrates one alternative to conventional machined tooling: press brake tooling 3D printed from fiber-reinforced polymer. 3D-printed punches and dies can be designed and built quickly and at lower cost than machined tools, enabling the company to get to production faster.

Centerline is a machining, fabrication and engineering business based in Greenwood, South Carolina. The company manufactures production parts and one-offs for customers in the electrical, power and consumer products industries. In addition to press brake forming, Centerline also offers laser cutting, welding, and milling and turning with both CNC and manual equipment.

Phil Vickery, company owner and president, recently added a MarkForged Mark Two composite 3D printer to complement this more conventional manufacturing capacity. Centerline regularly uses the printer to make jigs and fixtures for its own operations, as well as production parts for customers. But the hardness and strength of the materials available for the MarkForged printer—the main reason Vickery chose this 3D printer—also allows it to lend itself to the manufacture of press brake tooling.

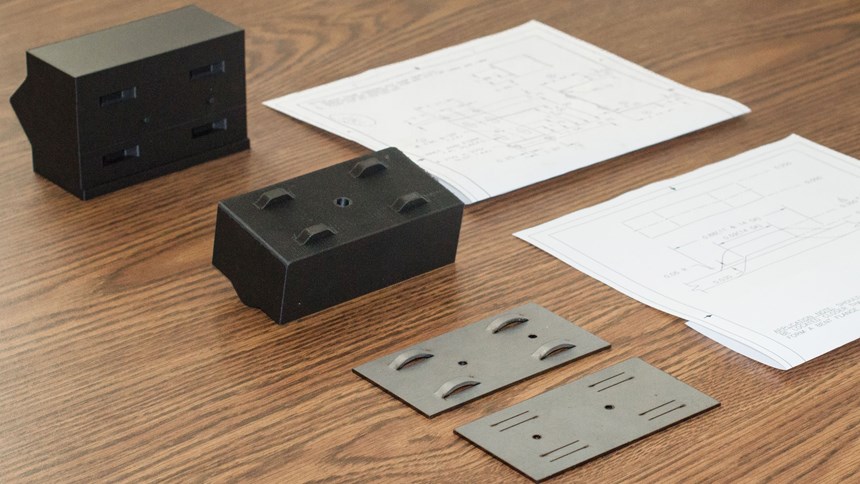

For the customer part pictured above, Centerline Engineered Solutions needed a specialized punch and die to lance and form 14-gauge steel plate. Machining this tooling from metal would have taken 12 to 24 hours of a machinist’s time in-house, Vickery says, and purchasing it from an outside supplier would likely have cost several thousand dollars.

Instead, the company designed the tooling and printed it on the MarkForged machine from Onyx material, a nylon matrix blended with chopped carbon fiber. The print was paused at strategic points to allow an operator to add 14-gauge steel inserts for extra support beneath critical features. The tooling was 3D printed in less than 48 hours, largely unattended, at a cost of only about $200.

In use on Centerline’s Trumpf press brake, the punch and die successfully withstands between 1 and 2 tons of pressure to lance the steel blank to customer depth specifications. See the 3D-printed punch and die in use in the first operation shown in the video below (the remaining work is performed using conventional metal tooling):

Centerline hasn’t yet put this tooling to the test in terms of longevity, but Vickery is confident that 3D-printed press brake tooling can support several hundred or perhaps several thousand runs. “From what we have seen thus far, 3D printing is for prototyping and small runs with light-grade sheet metal, and it has the potential to do proof of concept and short production runs,” Vickery says.

But he’s not looking at the 3D-printed parts as a permanent substitute for metal ones; rather, they are a solution for small batches or a fast-track into production for new parts. “When we have a new product or a new drawing from a customer that requires some type of specialized tooling, and they have a short production run, then I’ll first try it with a 3D-printed part,” he says. If the run requires thousands or tens of thousands, though, it’s worth making the piece out of metal. 3D printing can be a way to help customers work out new designs or a stopgap measure so that production can begin while machined metal tooling is in production.

“Customers in their designs are quite often trying new things and pushing their envelopes,” Vickery says. “3D printing allows me to make small enough quantities where I can give my customer the part for their initial launch and then convert it to a metal design longer term.”

Related Content

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreUnderstanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreCasting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreRead Next

Video: Additive Manufacturing Offers a Tooling Alternative

3D printing can offer a cost-effective alternative to conventionally produced tooling for those processes that depend on it.

Read MoreOne-Offs Without Tradeoffs

Does it have to be expensive to produce a one-off part? Does the one-off have to fall short of the manufactured part’s properties? A Boston-area 3D printer maker has an idea for how to produce components that are both low quantity and industrial quality.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)