With no need for molds or other tooling, additive manufacturing (AM) can deliver parts with less setup lead time than the existing supply chain, and with design innovations not possible through conventional methods. But for AM to be prepared to realize these advantages, it needs feedstock ready and waiting. Minimum order quantities may not apply to 3D printed parts, but scale can still be a limitation in acquiring the raw material.

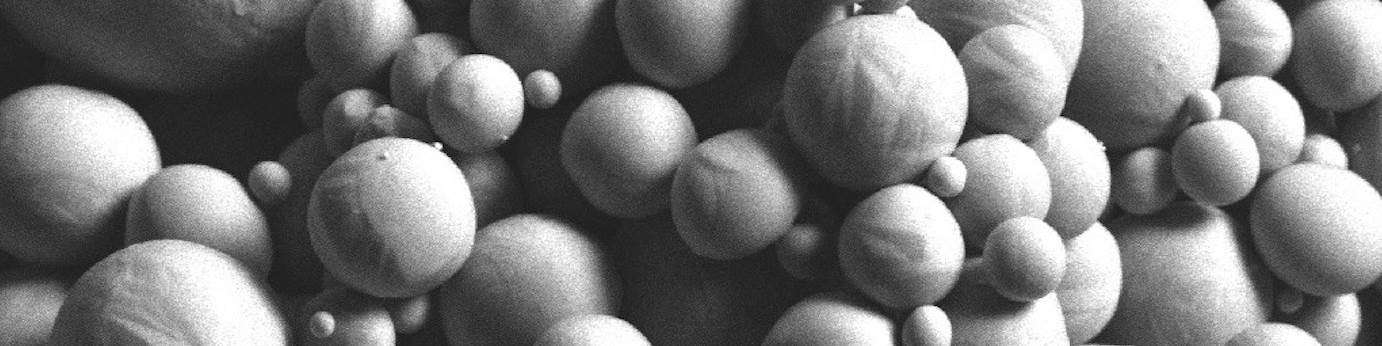

Metal powders in particular can be a bottleneck. Part of the challenge is that most of the gas atomizers used to make 3D printable metal powders were not originally built for this application, and are also utilized to produce materials for other manufacturing processes such as metal injection molding (MIM). Additive manufacturing does not command the full capacity of its material suppliers, and therefore its users can find themselves competing against other industries and applications for the capacity to make the materials they need.

Easing this bottleneck is the goal for KBM Advanced Materials, a recently announced venture backed by Koch Minerals & Trading and supported by supply chain partner Sumitomo Corporation of Americas. Headquartered in Fairfield, Ohio, but with distribution capacity throughout the United States, the company functions as an “inventory bridge” connecting metal powder suppliers with buyers in additive manufacturing and other advanced manufacturing industries through an online e-commerce portal.

“We buy it in tons and ship it in kilos,” says Kevin Kemper, CEO, to summarize the model. KBM Advanced Materials buys, stores and ships metal powders from multiple suppliers, which are all sold under the original manufacturer’s label. KBM’s bulk orders allow for passing cost savings onto buyers while providing a reliable, fast and easily accessible source of material. Customers in the lower 48 United States can schedule regular shipments of material or place orders as-needed for delivery within days through the e-commerce site. (Delivery to other parts of North America is also possible by ordering directly with a representative.)

The option to buy powder from a distributor is advantageous, Kemper says, particularly for small- to medium-sized service bureaus and additive manufacturers that may not keep large amounts of material on hand and could have difficulty placing a rush order of powder to fill a production run. Working through KBM, AM users like this will be able to order and receive powder in a timely fashion from the nearest distribution center.

“Not every job in AM is a planned job, and smaller orders of powder are harder to fill,” Kemper says. “This model makes procurement easy,” even when material orders are placed unexpectedly.

The platform is launching with Carpenter Additive, Höganäs AB and Tekna Holdings AS as its first material suppliers, and offering a selection of stainless steel, nickel, aluminum, titanium and cobalt alloy powders to start. In addition to distributing these and other powders, KBM also expects to be active in recapturing excess material. The company will accept back overused powder for refurbishment or recycling, and credit the customer for the material to incentivize these returns.

Later this year, KBM expects to expand its distribution model to Europe, and in 2022 to Asia. More types of materials and other 3D printing consumables could also travel along its distribution network.

“Additive manufacturing is difficult enough already,” Kemper says, “so we’re looking for and reducing the friction points.”

Related Content

Aluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)