Materialise’s Translucent Material Expands Eyewear Design Capabilities

The company opens up new design possibilities with the fusion of 3D printing and translucent material.

Share

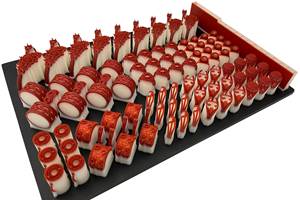

Materialise has expanded its material portfolio with a translucent material for creating 3D printed eyewear. This addition to Materialise's portfolio enables eyewear manufacturers to merge the design advantages of 3D printing with consumer demand for translucent eyewear collections. The company says the introduction of this material opens the door to visually compelling collections that will shape the future of eyewear fashion.

As eyewear manufacturers embraced 3D printing for its exceptional design capabilities, they often encountered a practical limitation: the technology couldn't replicate the translucent aesthetics traditionally associated with acetate frames. The introduction of a new translucent material empowers eyewear brands to blend translucency with the design flexibility of 3D printing, enabling designers to move beyond what is possible with acetate.

The translucent material is the result of five years of extensive trialing of over 50 different materials against the gold standard of established eyewear materials, including tests for biocompatibility, thermal resilience and impact resistance.

“The convergence of 3D printing technology with the advent of innovative translucent materials opens up a realm of exhilarating design possibilities for eyewear designers,” says Alireza Parandian, head of global business strategy, wearables at Materialise. “In the past decade, 3D printing has introduced a new level of freedom that offers designers unlimited creativity to craft intricate and customized frames. Moving forward, the introduction of translucent materials to the 3D printing palette will bring a new dimension to eyewear aesthetics. These materials, with their ethereal qualities, transform eyeglass frames into works of art, offering a unique interplay of complexity and depth.”

3D printing can offer multiple advantages for manufacturing eyewear, including shorter development cycles, faster routes to market and sustainable credentials. It also enables designers to experiment with form — offering the ability to play with complex shapes, intricate structures and textures that are impossible to replicate with traditional production techniques. Over the last decade, this has led to the widespread adoption of 3D printed eyewear across the industry.

The company says this marriage of technology and material innovation promises to redefine the future of eyewear design, offering designers a diverse array of new options to enhance both their vision and style.

- Learn about Materialise’s efforts in the medical field after it opened a medical 3D printing facility in Plymouth, Michigan. There, the company specializes in the 3D printing of personalized titanium cranio-maxillofacial (CMF) implants for more patient-specific care.

- Materialise is also working in aerospace as it partners with GKN Aerospace to propel additive manufacturing in aviation. Materialise supported the delivery of the additively manufactured wing tip for Eviation’s Alice, the world's largest all-electric aircraft, which made its maiden flight in 2022.

Related Content

EOS Launches Digital Foam Architects Network

EOS created the collaborative additive manufacturing alliance to accelerate time-to-market for 3D printed foam applications.

Read MoreChromaMotive D65 Parts Perform Well in Range of Extreme Temperatures

Formnext 2023: The Shore D thermoset polyurethane is well suited for applications that have varying temperature requirements, in a range extreme cold to elevated temperatures from -30 up to 120°C.

Read More3D Systems Offers MJP 300W Printer, Wax Material for Advanced Jewelry Additive Manufacturing

The combination of the MJP 300W jewelry printer and VisiJet Wax Jewel Ruby enables jewelry designers to more efficiently achieve new designs with greater design freedom and improved surface finish.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More